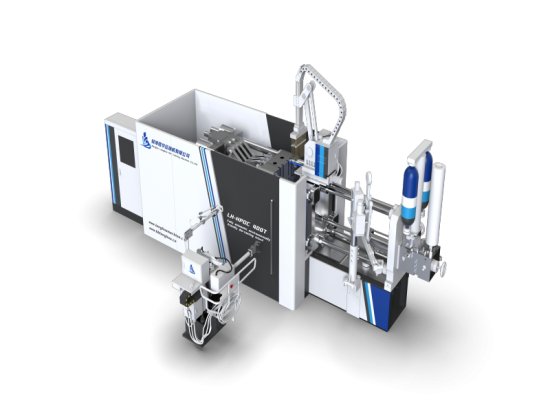

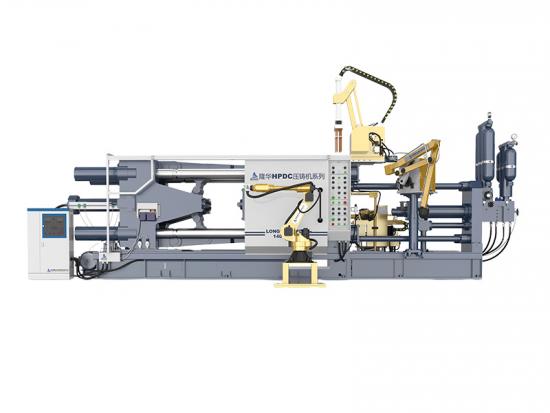

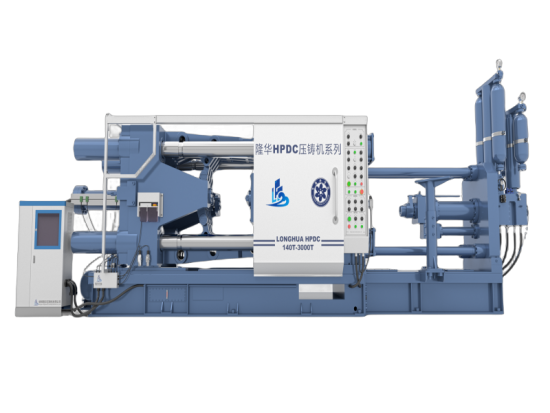

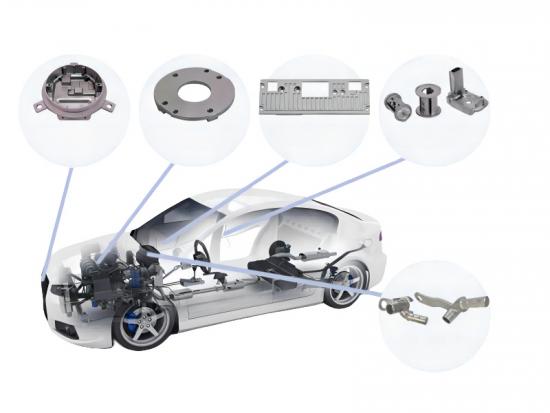

The intelligent horizontal die-casting machine for energy hydraulic valve parts is a die-casting equipment

specially used to produce energy hydraulic valve parts. Its features usually include:

1. Horizontal design: The horizontal design makes the operation more convenient, is more suitable for

larger-sized workpieces, and also reduces the labor intensity of workers.

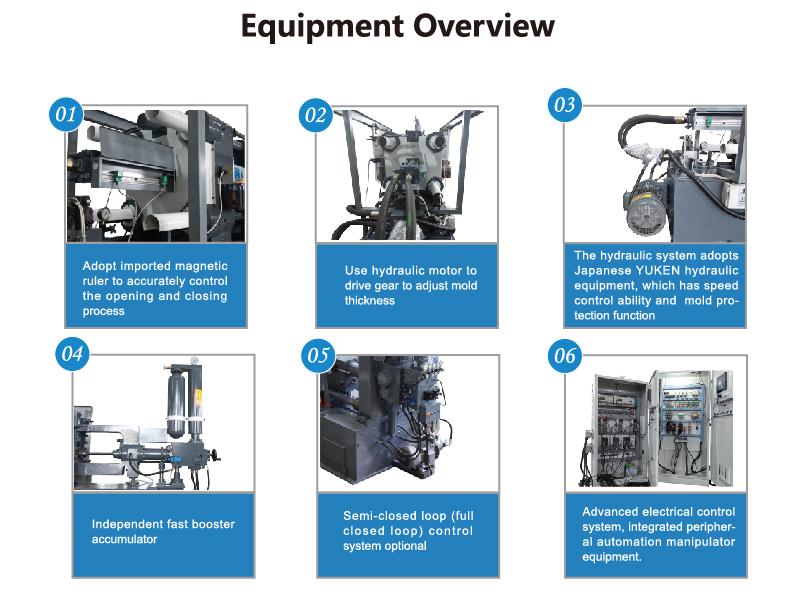

2. High-precision production: The intelligent control system can realize a high-precision die-casting process

to ensure that the size and shape of the valve parts meet the design requirements.

3. Efficient production: Die-casting machines usually have fast production cycles and high productivity, and

can meet the needs of mass production.

4. Intelligent control system: Equipped with an advanced intelligent control system, it can monitor and adjust

the die-casting process in real time, improving the stability and efficiency of production.

5. Quick mold replacement: Designed to quickly replace molds to adapt to the production needs of valve

parts of different shapes and sizes, improving production flexibility and efficiency.

6. Energy saving and environmental protection: Using advanced energy-saving technology and

environmentally friendly materials reduces energy consumption and waste emissions, and meets

environmental protection requirements.

7. High-pressure injection system: It is usually equipped with a high-pressure injection system, which can

inject metal alloy into the mold cavity at high pressure to ensure that the casting is fully filled and

improves the density and integrity of the casting.

8. Automated control: Equipped with an automated control system, it can realize automated operations of

the entire production process, including injection, cooling, mold replacement, etc., improving production

efficiency and consistency.

9. Quality control: Strict quality control is carried out throughout the production process to ensure that the

size, surface quality and function of the valve parts meet the design requirements and customer needs.

| LH series of standard parameter table (220 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 2200 |

| Opening stroke | mm | 400 |

| Die thickness(Min--Max) | mm | 200~600 |

| Space between tie bars | mm | 510*510 |

| Ejector stroke | mm | 90 |

| Ejector force | KN | 120 |

| Injection position(0 as center) | mm | 0,-140 |

| Injection force(intensification) | KN | 270 |

| Injection stroke | mm | 370 |

| Plunger diameter | mm | ¢40 --¢70 |

| lnjection weight(aluminum) | Kg | 2.8 |

| Casting pressure (intensification) | MPa | 152/106/77 |

| Max. casting area(40Mpa) | CM2 | 550 |

| Injection plunger penetration | mm | 140 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 11 |

| Dimensions (L*W*H) | m | 5.8*1.6*2.4 |

| Machine lifting reference weight | T | 8.5 |

| Oil tank capacity | L | 600 |

(Due to the continuous progress of science and technology,the picture,parameter configuration,etc,

will not be changed without notice)

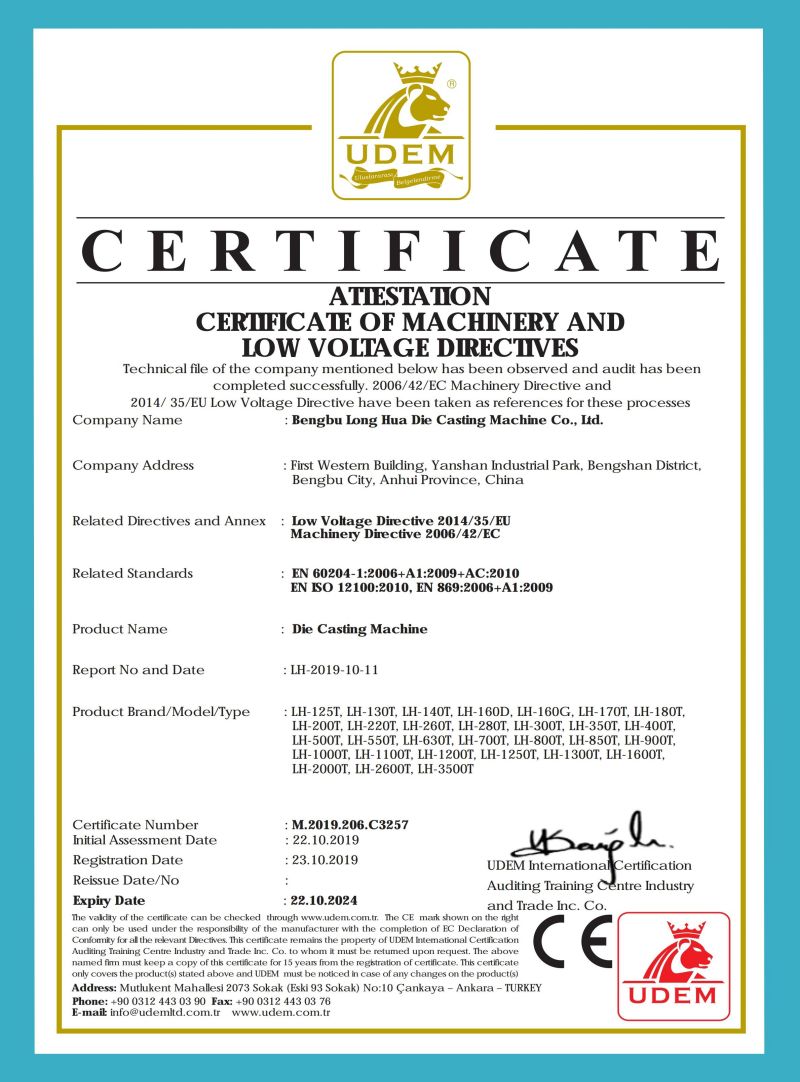

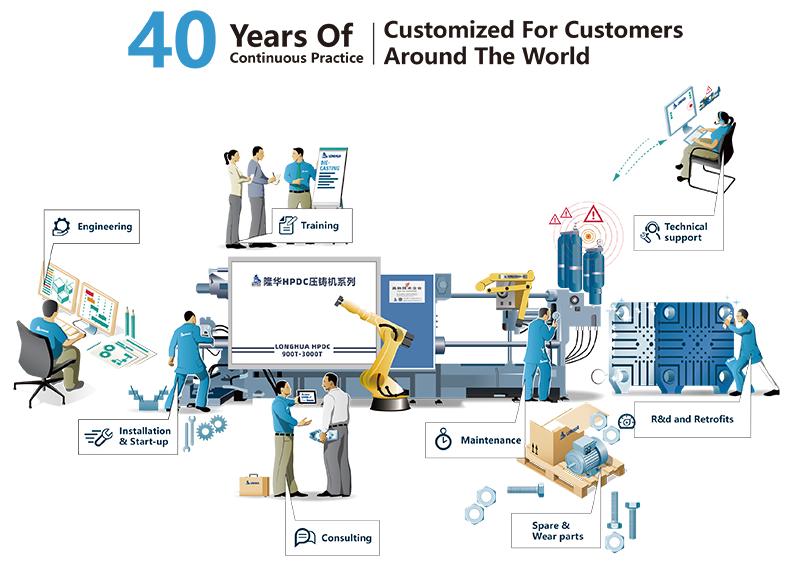

ABOUT US

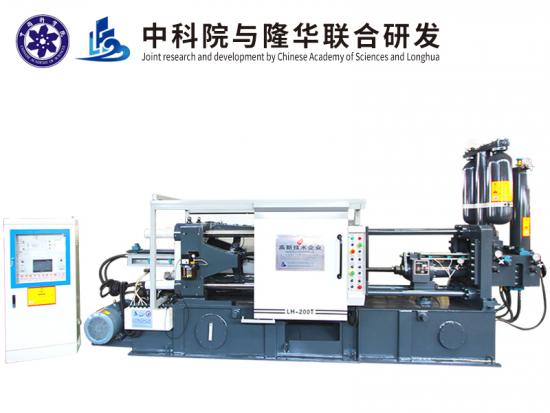

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,

China.It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting

industry for several decades.The company focuses on research,development,production,and

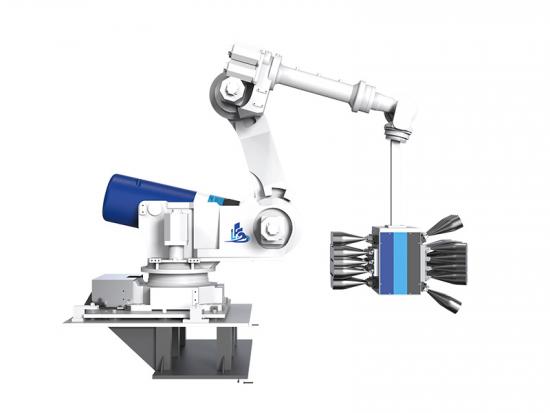

sales of various types of die casting machines.The company's product range covers cold chamber

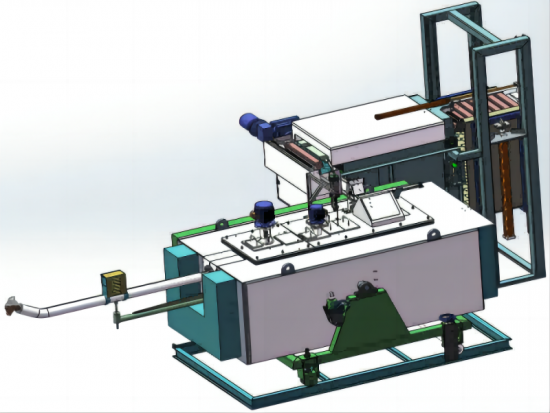

die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of

die-casting machines to meet the needs of different customers.