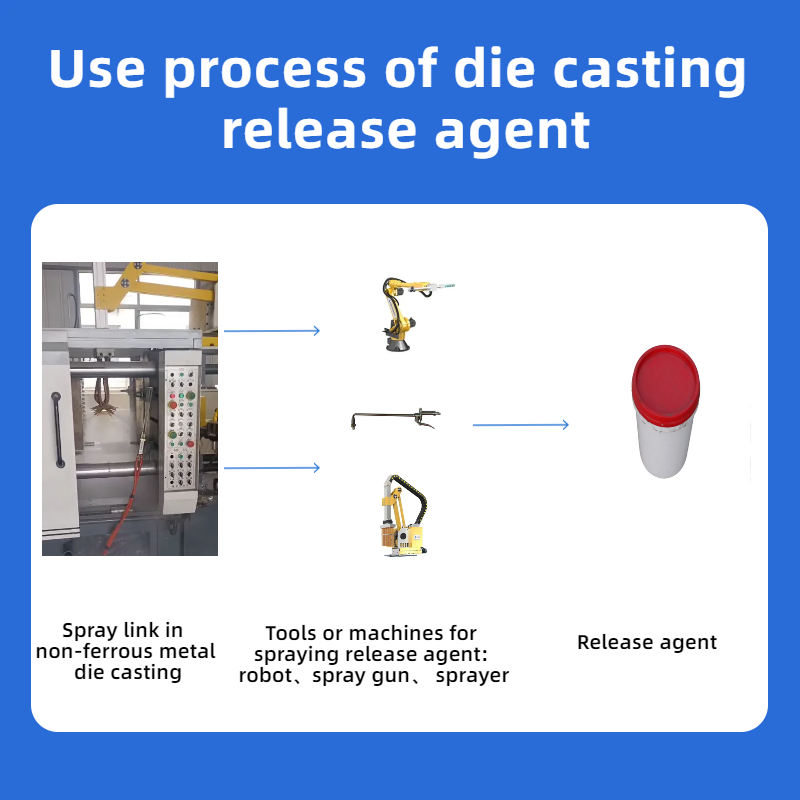

In the die-casting industry, release agents are substances used to coat the surface of the mold during the

die-casting process to facilitate smooth demoulding. The following are some characteristics of release agents:

1. Mold release: Mold release agent has good mold release performance, which can effectively reduce the

adhesion between the metal and the mold surface, making the die casting easy to come out of the mold,

reducing product damage and production cycle.

2. Degradability: Release agents usually have certain degradability and can quickly evaporate or decompose

at high temperatures. They will not remain on the surface of die castings and avoid the impact of subsequent

process steps.

3. High temperature resistance: Since the high temperature is involved in the die-casting process, the release

agent needs to have good high temperature resistance and be able to maintain a stable mold release effect

under high temperature conditions.

4. Does not pollute the metal surface: The release agent needs to comply with environmental standards and will

not pollute or affect the surface quality of the die casting to ensure that the product quality meets the requirements.

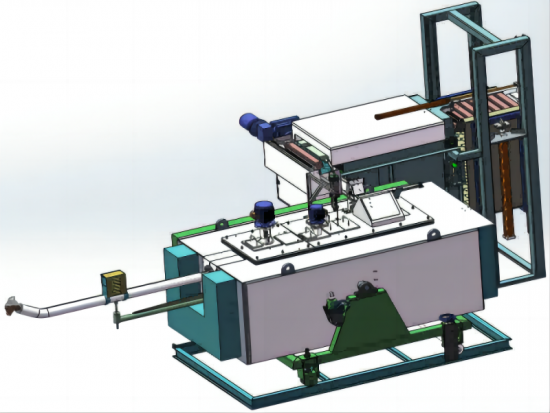

5. Uniform coating: The release agent needs to have good coating performance and can evenly cover the mold

surface to ensure uniform overall surface quality of the die casting.

6. Easy to clean: The release agent needs to be easy to clean after the die-casting is completed, so that it will not

cause trouble to subsequent processing and surface treatment processes, and improve production efficiency.

7. Stability: The release agent needs to maintain stability during long-term storage and use, and will not affect the

release effect due to long storage time or changes in environmental conditions.

8. Adaptability: The release agent needs to be able to adapt to different types of die-casting materials and mold

surfaces, maintain a stable mold release effect, and be suitable for various die-casting process conditions.

1.Performance characteristics

It does not burn and has good lubrication properties, making die castings smooth and shiny.It does not contain powder, so the mold does not need to be frequently dismantled and repaired. It can

extend the service life of the mold and save man-hours. There is no corrosion on the castings and mold

equipment. The casting products have clear outlines and smooth and traceless surfaces.

Does not stick to the mold, does not turn black, has low odor, is environmentally friendly, and is not

prone to accumulation on the mold surface, making it easy to clean.

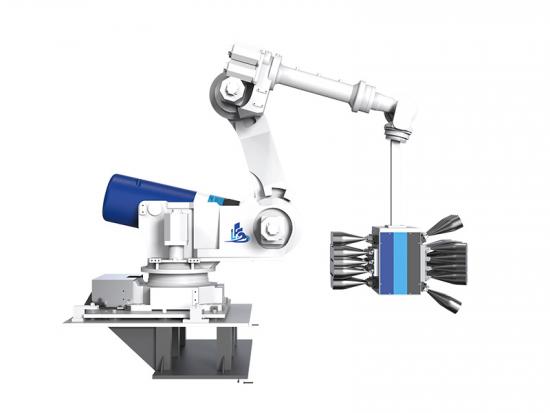

Provide a good working environment for production.2. How to use

Determine the dilution ratio through trials based on on-site usage conditions.

3. Precautions

To protect the environment, please do not place it in the open air.

Do not mix or use the same container with other different types of liquids.

Clean the container well and replace or replenish it regularly.

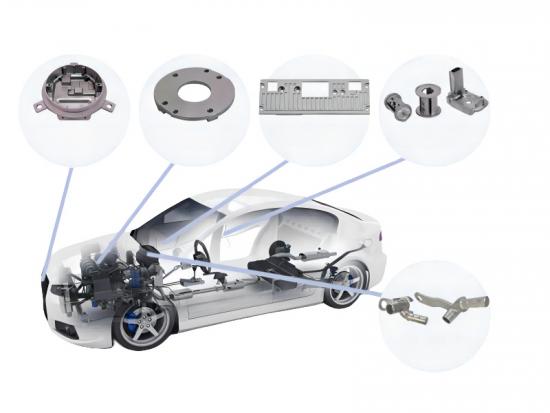

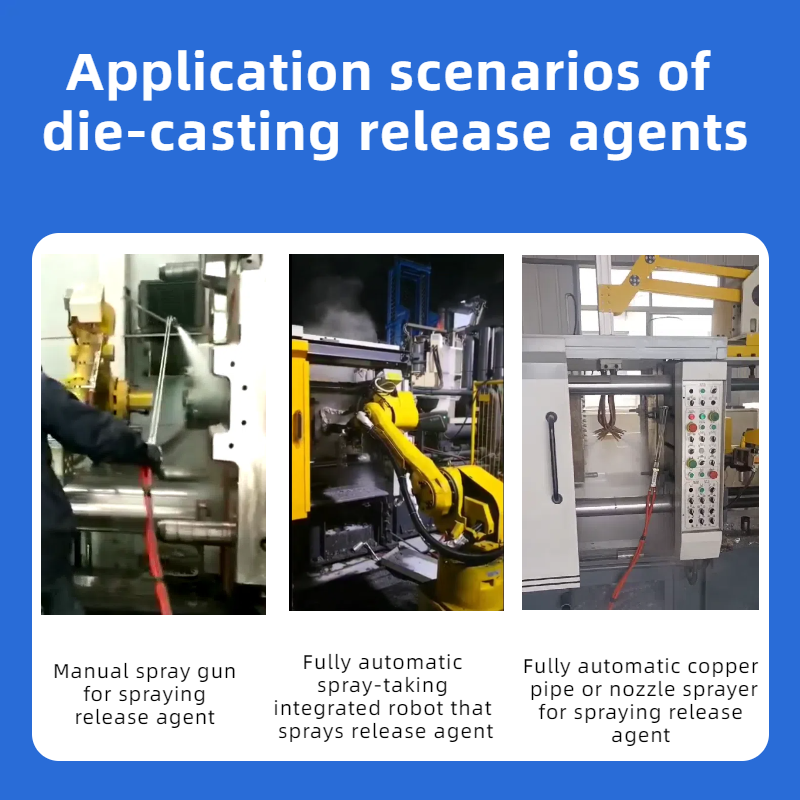

4.Usage scenarios

Automobile industry, electromechanical industry, hardware industry, communication industry