Die casting machine is mainly composed of mould closing mechanism, injection mechanism, hydraulic system and electric control system.

In addition, the die casting machine has parts and bases, other devices, auxiliary devices and other parts.

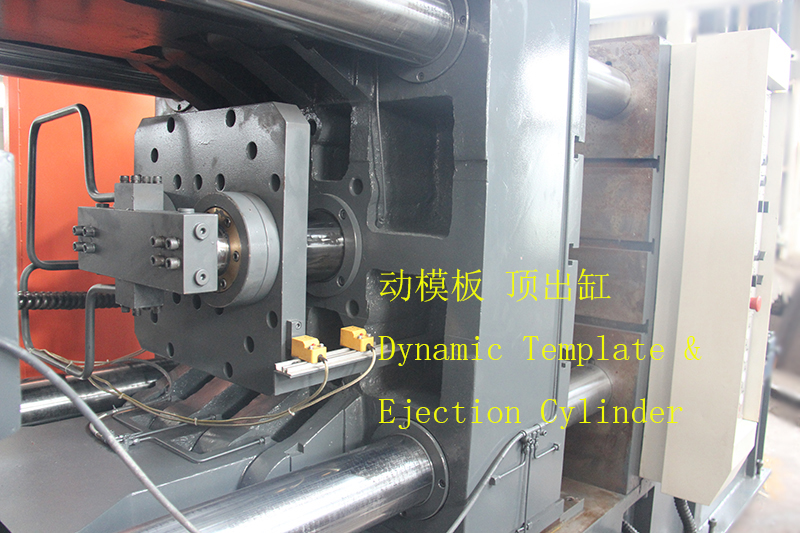

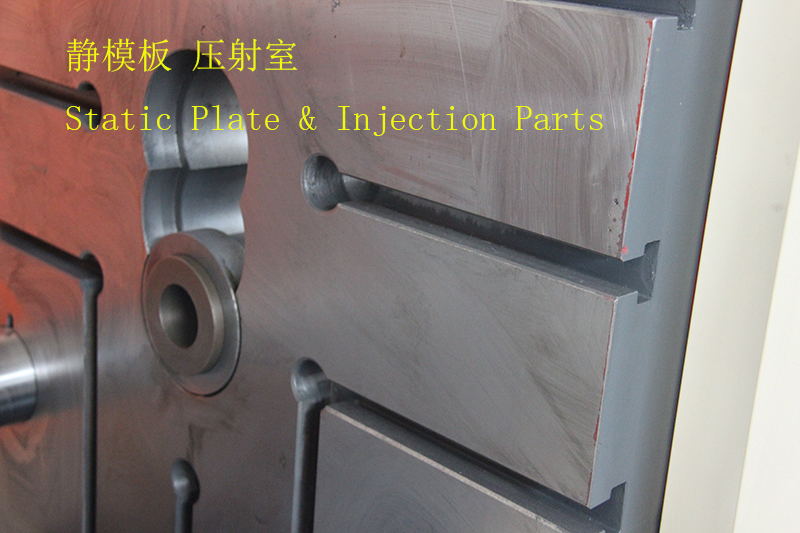

Die closing mechanism: Drives the die to close and open.

When the mold is closed, it has enough ability to lock the mold to ensure that the parting surface of the mold will not expand during the process of injection filling. The clamping force of the mold is known as the clamping force (also known as the clamping force), the unit is thousand kN (kN), which is the primary parameter to characterize the size of die casting machine.

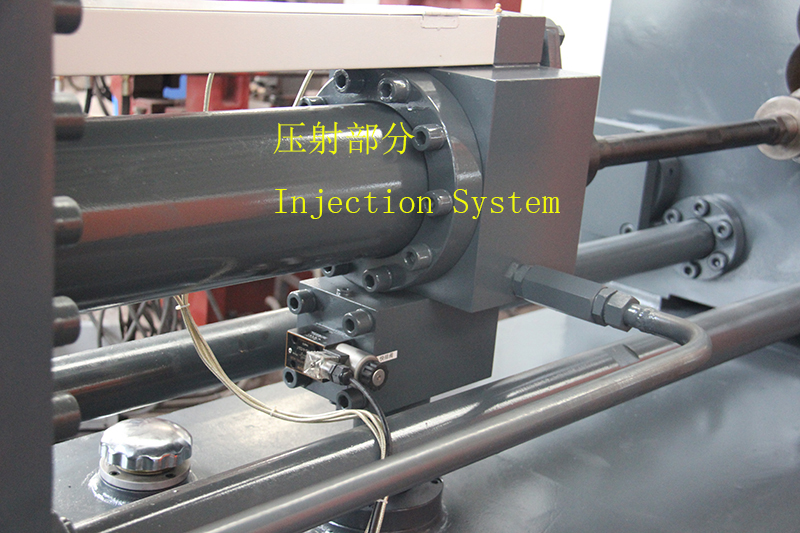

Injection mechanism: push the metal liquid in the pressure chamber at a specified speed, and have enough energy to make it flow through the runner and gate in the mold, and then fill the mold cavity, and then maintain a certain pressure transfer to the solidifying metal liquid, until the die casting.

After the injection action is completed, the injection punch returns to reset.

Hydraulic system: provide enough power and energy for the operation of die casting machine.

Electrical control system: control the operation of each mechanism of the die casting machine according to the predetermined procedure.