Magnesium alloys offer advantages such as light weight, high specific strength, high specific elastic modulus, high damping and shock absorption properties, and high thermal conductivity. Additionally, they cause little corrosion to casting molds, resulting in a long service life of the molds. The magnesium alloy die castings produced by this production line exhibit excellent dimensional stability, are not prone to sticking to molds, and the molds are less likely to crack. They have a small draft angle and can undergo surface treatments such as anodizing and surface coating in acidic or alkaline environments to enhance surface corrosion resistance. At present, they have been widely used in high-tech fields such as automobile manufacturing and communication equipment. For example, in the field of automobile manufacturing, they can produce various components such as automobile instrument panel skeletons, doors, and steering wheels, meeting the demand for automobile lightweighting and improving the overall performance of automobiles.

The magnesium alloy die casting production line of Bengbu Longhua Die Casting Machine Co., Ltd., with its characteristics of safety, reliability, high efficiency, energy saving, and excellent quality, takes a leading position in the industry. Whether in the domestic market or the international market, it can provide customers with high-quality products and services, helping enterprises stand out in the fierce market competition and work together to create a brilliant future.

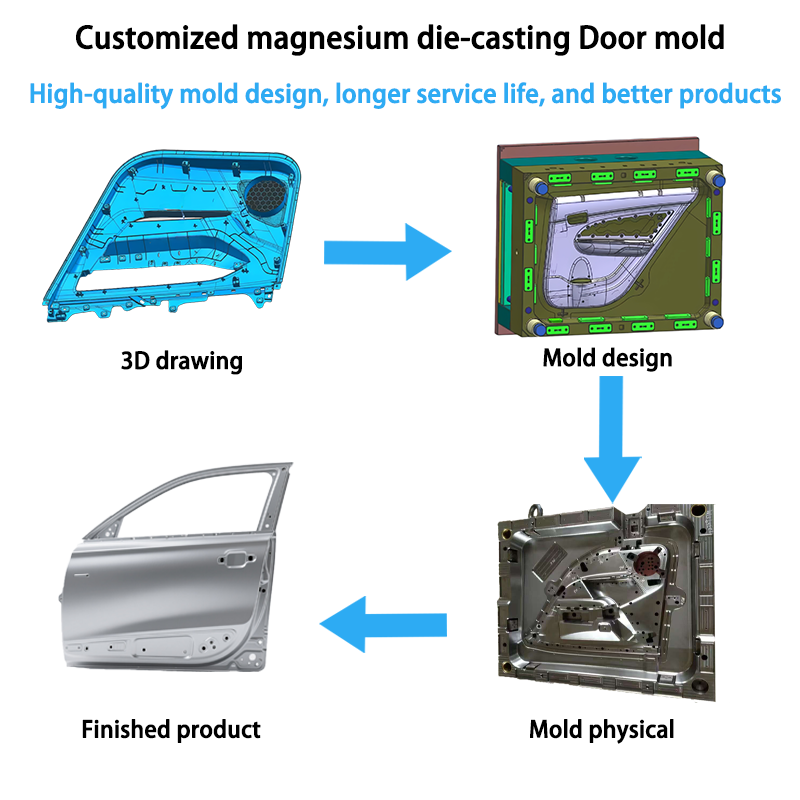

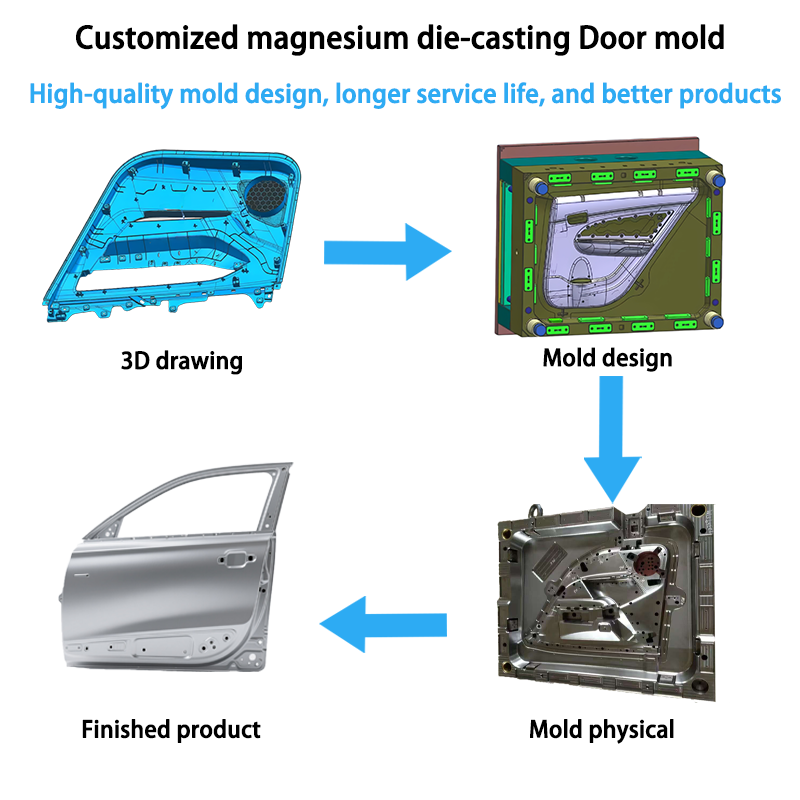

Customized magnesium die-casting Door mold

The Bengbu Longhua magnesium alloy door side panel die - casting production line is a specialized production solution tailored for the automotive industry, characterized by high efficiency, precision, and safety.

This production line relies on the company's independently developed large - scale magnesium alloy explosion - proof die - casting equipment. By combining the structural characteristics and production requirements of door side panels, it realizes an integrated process from the melting of magnesium alloy raw materials, quantitative pouring to die - casting forming. In terms of safety performance, it inherits the company's core explosion - proof technology. Through multiple gas protection, precise temperature control, and anti - leakage design, it fundamentally eliminates potential safety hazards in the magnesium alloy processing process, ensuring stable and reliable production throughout the entire process.

In terms of production precision, the production line is equipped with a high - precision mold positioning system and an intelligent pressure control system. It can accurately control various parameters during the die - casting process, keeping the dimensional tolerance of door side panels within a very small range, thus ensuring the consistency and assembly precision of the products. Meanwhile, taking advantage of the magnesium alloy's light weight and high strength, the produced door side panels not only meet the structural strength requirements of the automobile body but also significantly reduce the weight of the doors, contributing to the lightweight of automobiles and improving fuel economy and endurance.

In addition, the production line adopts an intelligent production management system, which can realize real - time monitoring, analysis, and traceability of production data, greatly improving production efficiency and the stability of product quality. One production line can complete the die - casting production of dozens of door side panels per hour, which can meet the mass production needs of large automobile manufacturers.

The Bengbu Longhua magnesium alloy door side panel die - casting production line, with its advanced technology, reliable performance, and efficient production capacity, provides a high - quality production solution for magnesium alloy parts in the automotive industry, helping automobile manufacturing enterprises take solid steps on the path of lightweight and energy - saving development.

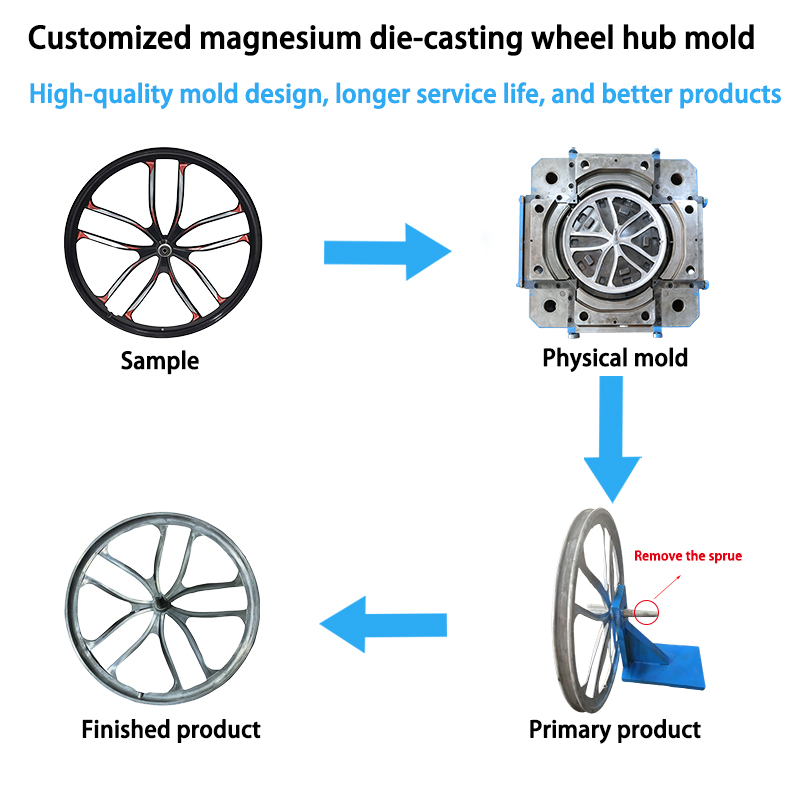

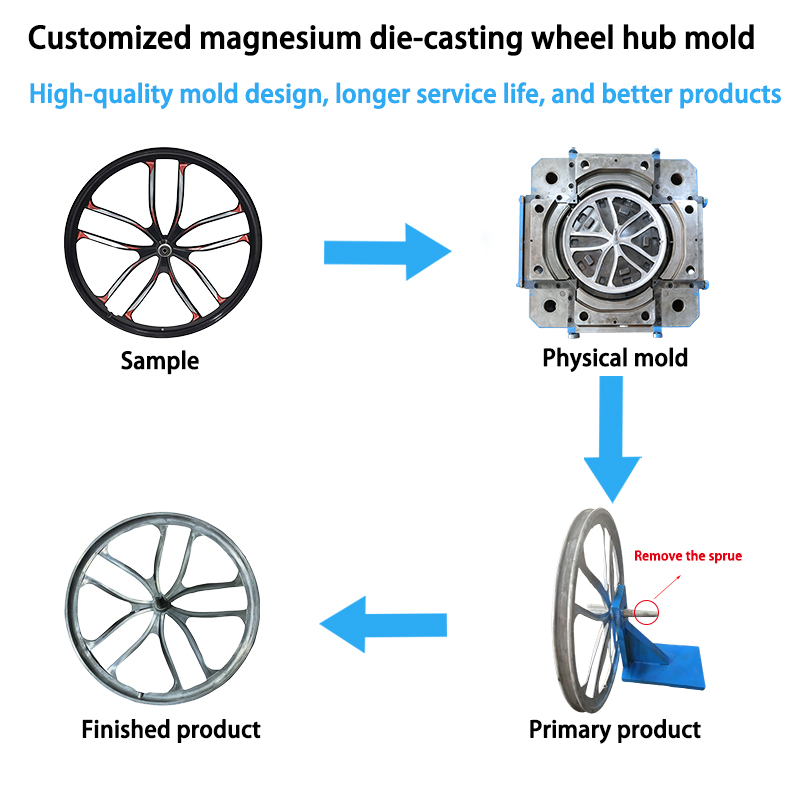

Customized magnesium die-casting wheel hub mold

I am an operator of Bengbu Longhua Die Casting Machine Co., Ltd. Here is the text introduction about the magnesium alloy bicycle wheel hub die-casting production line to be uploaded to the official website:

The Bengbu Longhua magnesium alloy bicycle wheel hub die-casting production line is a specialized production system developed in response to the bicycle industry's demand for lightweight and high-strength components.

This production line integrates the company's accumulated core technologies in magnesium alloy die-casting over the years, adopting an integrated die-casting process to achieve efficient connection from the melting of magnesium alloy raw materials, precise pouring to the forming of wheel hubs. In terms of safety assurance, it is equipped with a complete explosion-proof system, including inert gas protection devices, real-time temperature monitoring and abnormal warning mechanisms, ensuring the safety of magnesium alloy during high-temperature processing and laying a solid foundation for stable production.

Considering the strict requirements of bicycle wheel hubs for strength and precision, the production line is equipped with high-precision molds and an intelligent pressure control system, which can accurately control key parameters such as pressure, speed and time during the die-casting process, enabling the dimensional accuracy of the wheel hubs to reach a high standard and ensuring their good stability and durability during riding. At the same time, the magnesium alloy material itself has the characteristic of light weight. The bicycle wheel hubs die-cast by this production line are significantly lighter than those made of traditional materials, which can effectively reduce riding resistance and improve riding portability and flexibility.

In terms of production efficiency, the production line has realized a high degree of automated operation, and the process from raw material input to finished product output has been optimized. A single production line can complete the die-casting production of dozens of wheel hubs per hour, which can meet the mass production needs of bicycle manufacturers. In addition, the intelligent production management system can track and analyze production data in real time, facilitating timely adjustment of production parameters to ensure the consistency of product quality.

With its ability to produce lightweight, high-strength and high-precision products, as well as its efficient and safe production performance, the Bengbu Longhua magnesium alloy bicycle wheel hub die-casting production line provides a high-quality component production solution for the bicycle industry, helping the bicycle industry develop in a more lightweight and efficient direction.

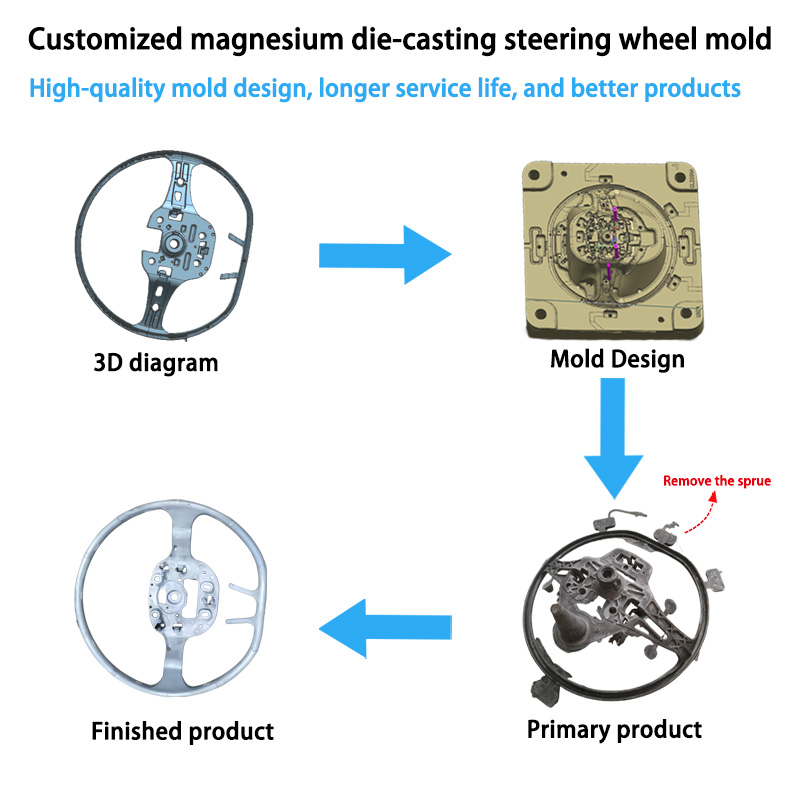

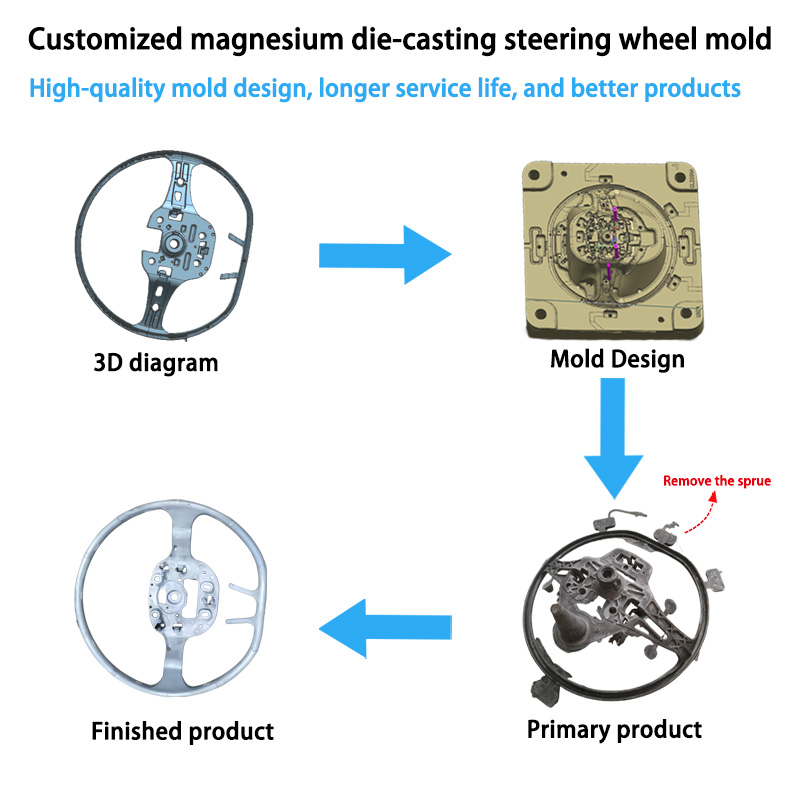

Customized magnesium die-casting steering wheel mold

The Bengbu Longhua magnesium alloy automobile steering wheel die-casting production line is a professional production system integrating safety, precision and efficiency, built for the automotive manufacturing field, and is committed to meeting the strict requirements of automobile steering wheels for material performance and process accuracy.

This production line inherits the company's technical accumulation in the field of magnesium alloy die-casting, and adopts a customized integrated die-casting process, covering the entire process from precise proportioning of magnesium alloy raw materials, constant temperature melting, quantitative pouring to integral forming of the steering wheel. In terms of safety protection, it uses a mature explosion-proof technology system, equipped with multiple inert gas protection devices, a fast-response temperature abnormality monitoring system and a leak-proof sealing structure, which helps to avoid safety risks in high-temperature processing of magnesium alloys and ensures stable and controllable production throughout the entire process.

Considering that the automobile steering wheel is closely related to driving safety, the production line is equipped with a high-precision mold positioning system and an adaptive pressure regulation module, which can accurately control more than 20 key parameters such as pressure holding time, alloy flow rate and cooling rate during the die-casting process, so that the dimensional tolerance of the steering wheel frame is controlled within 0.05mm, which is conducive to achieving good adaptation with airbags, steering columns and other components. At the same time, relying on the characteristics of high specific strength and good shock absorption of magnesium alloy, the produced steering wheel is more than 30% lighter than the traditional aluminum alloy scheme, and can improve the stability of driving control through the damping characteristics of the material itself, reducing hand fatigue during long-distance driving.

In terms of production efficiency, the production line realizes full-process automated operation, integrating auxiliary processes such as automatic part taking, burr cleaning and online inspection. A single line can produce 80-100 qualified products per hour, which can meet the mass production needs of mainstream automobile manufacturers. The equipped intelligent MES system can collect process data in real time and generate quality traceability reports, and continuously optimize production parameters in combination with algorithms, so that the product qualification rate remains at a high level.

The Bengbu Longhua magnesium alloy automobile steering wheel die-casting production line, with reliable safety guarantee, precise process control and efficient production capacity, provides automobile manufacturers with a full-cycle solution from process design to mass production, helping the automotive industry continue to develop on the road of lightweight upgrading and safety performance improvement.