Feature

Features of motorcycle parts die-casting machine:

1. Miniaturized design: Motorcycle parts are usually relatively small, so motorcycle parts die-casting

machines often adopt miniaturized designs to adapt to the production needs of small parts.

2. High strength requirements: Motorcycle parts usually need to withstand high pressure and impact,

so the motorcycle parts die-casting machine needs to have sufficient die-casting capacity and material

strength to ensure that the parts produced have good strength and durability.

3. Precision machining: The size of motorcycle parts is usually small, so the accuracy requirements are

high. The motorcycle parts die-casting machine needs to have high-precision processing capabilities to

ensure that the size and shape of the parts meet the design requirements.

4. High-efficiency production: The motorcycle market is highly competitive, and production efficiency is

crucial to manufacturers. Therefore, motorcycle parts die-casting machines need to have high-efficiency

production capabilities and be able to produce large quantities of parts quickly and stably.

5. Diversified materials: Motorcycle accessories usually use a variety of materials, including aluminum

alloy, magnesium alloy, etc. The motorcycle parts die-casting machine needs to have the ability to adapt

to the casting of multiple materials to meet the production needs of different parts.

6. Flexibility and adjustability: The designs of motorcycle accessories are diverse, so the motorcycle parts

die-casting machine needs to have strong flexibility and adjustability, and can be adjusted and customized

according to the requirements of different accessories.

7. Quality Control: The quality of motorcycle accessories is crucial to safety and performance. The

motorcycle parts die-casting machine needs to have a strict quality control system to ensure that the

quality of the parts produced is stable and reliable.

8. Energy conservation and environmental protection: Although production efficiency is crucial, energy

conservation and environmental protection are also important trends in modern industry. The motorcycle

parts die-casting machine needs to be energy-saving and environmentally friendly to reduce energy

consumption and emissions and comply with environmental protection requirements.

| LH series of standard parameter table (450 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 4500 |

| Opening stroke | mm | 580 |

| Die thickness(Min--Max) | mm | 320~800 |

| Space between tie bars | mm | 760*660 |

| Ejector stroke | mm | 120 |

| Ejector force | KN | 240 |

| Injection position(0 as center) | mm | 0,-220 |

| Injection force(intensification) | KN | 450 |

| Injection stroke | mm | 580 |

| Plunger diameter | mm | ¢70 ¢80 ¢90 |

| lnjection weight(aluminum) | Kg | 6.9 |

| Casting pressure (intensification) | MPa | 135/117/92 |

| Max. casting area(40Mpa) | CM2 | 1250 |

| Injection plunger penetration | mm | 250 |

| Diameter of pressure chamber flange | mm | 130 |

| Height of pressure chamber flange | mm | 15 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 22 |

| Dimensions (L*W*H) | m | 7.7*2.1*3.1 |

| Machine lifting reference weight | T | 20 |

| Oil tank capacity | L | 1000 |

will not be changed without notice)

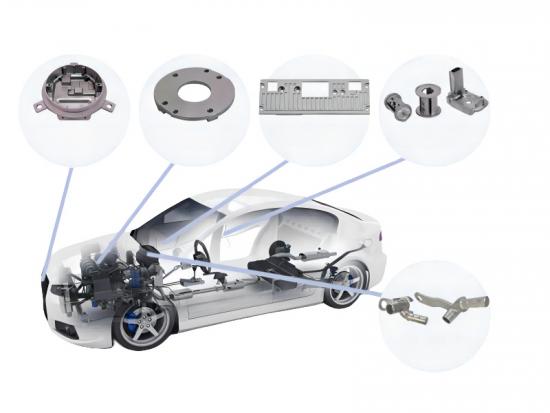

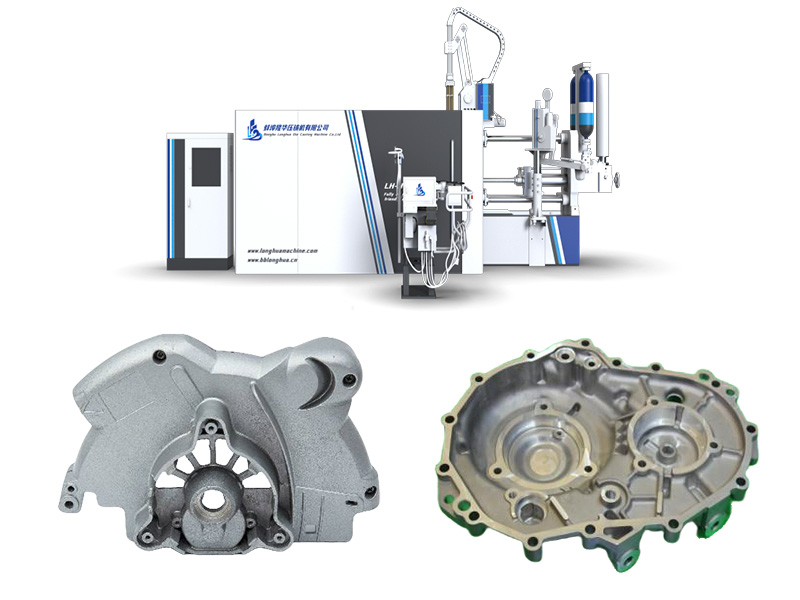

Die-cast motorcycle parts are motorcycle parts manufactured using die-casting technology, usually

made of aluminum alloy, magnesium alloy or other metal alloys. The manufacturing process of

these accessories involves heating the metal to a liquid state and then injecting it into a predesigned

mold through high pressure, ultimately forming the desired motorcycle accessory product. Here are

some common types of die-cast motorcycle accessories and their features:

1.Engine parts: Die-casting technology can be used to manufacture various parts of motorcycle

engines, such as engine blocks, cylinder heads, crankcases, etc. These parts often require high

strength and wear resistance to ensure proper engine operation and long-term reliability.

2.Frame components: Die-casting technology can also be used to manufacture various components

of motorcycle frames, such as frame side panels, frame connectors, etc. These components usually

need to have excellent strength and rigidity to ensure the stability and safety of the vehicle while

driving.

3.Wheel parts: Die-casting technology can manufacture various parts of motorcycle wheels, such as

hubs, spokes, rims, etc. These parts need to be lightweight and high-strength to improve vehicle

handling and driving stability.

4.Appearance decoration parts: Some motorcycle accessories are designed as appearance decoration

parts, such as fuel tank caps, seat back shells, etc. These accessories often feature exquisite designs

and finishes that enhance the vehicle's appearance and match the overall style of the vehicle.

5.Control system parts: Various parts of the motorcycle control system, such as brake handles,

clutch handles, etc., can also be manufactured through die-casting technology. These parts need

to have good wear resistance and operating feel to ensure vehicle handling and driving safety.

ABOUT US

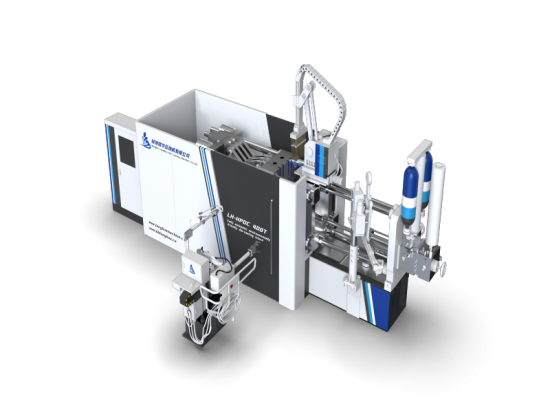

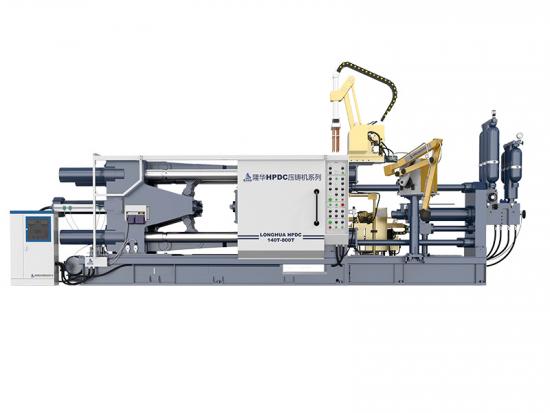

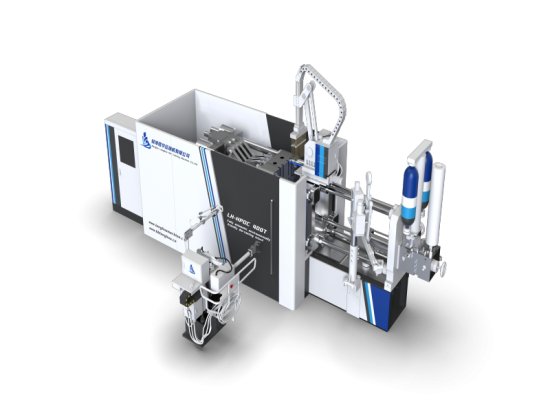

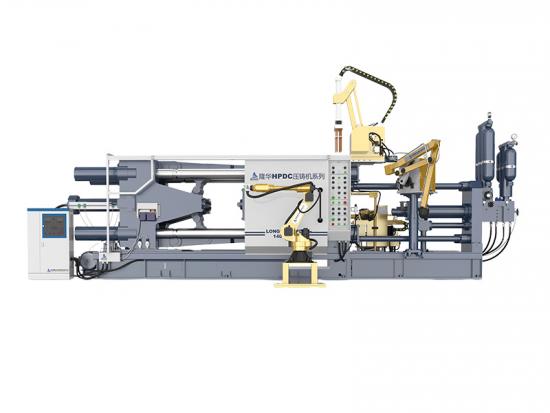

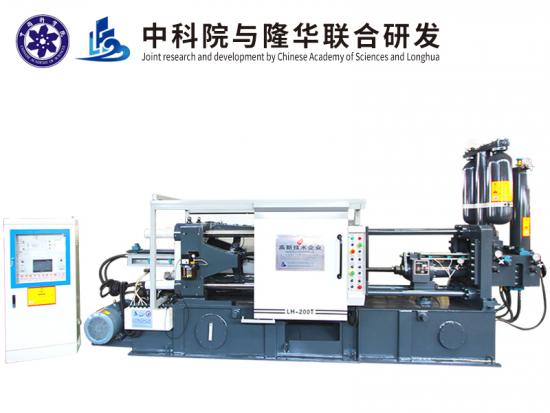

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,

China.It specializes in the manufacturing of die casting machines and related equipment.

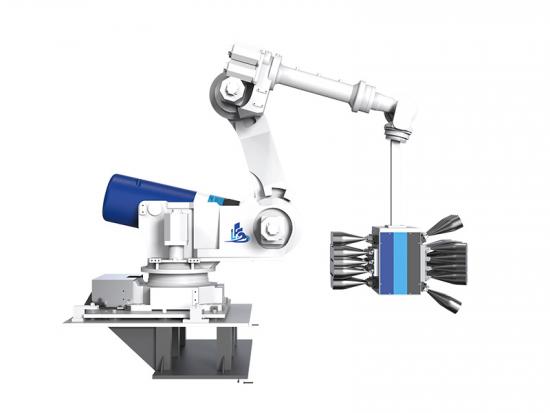

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting

industry for several decades.The company focuses on research,development,production,and

sales of various types of die casting machines.The company's product range covers cold chamber

die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of

die-casting machines to meet the needs of different customers.

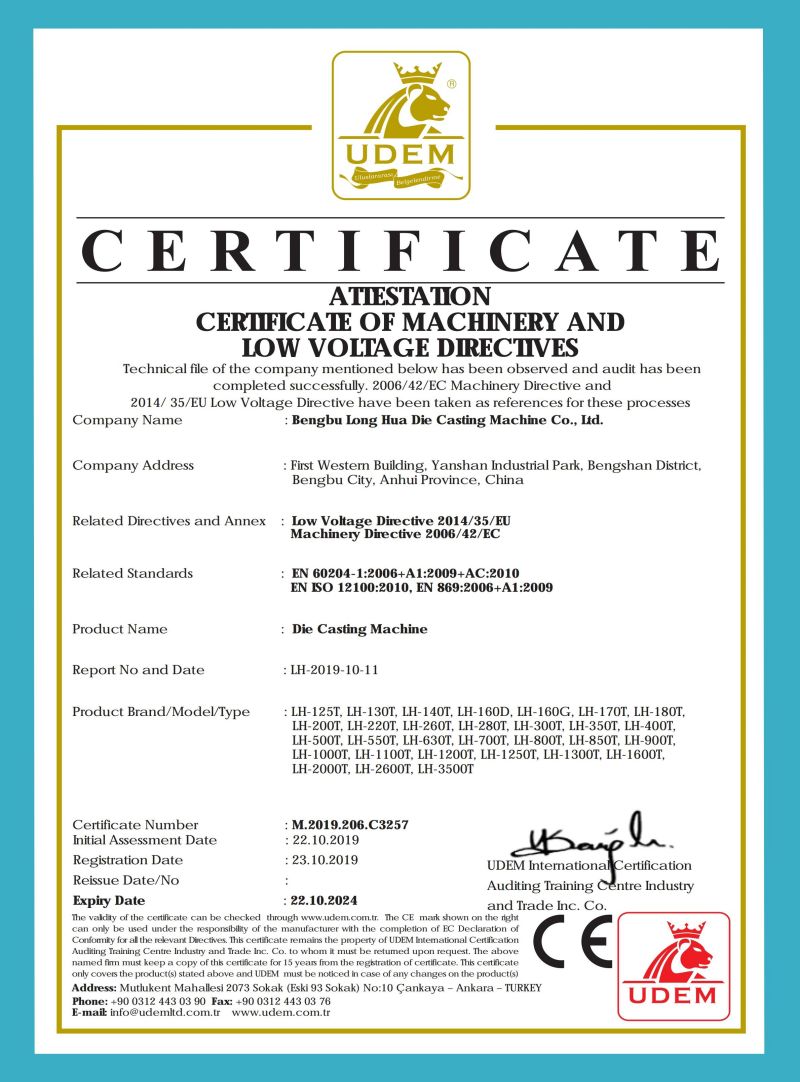

CE certificate