Product Details

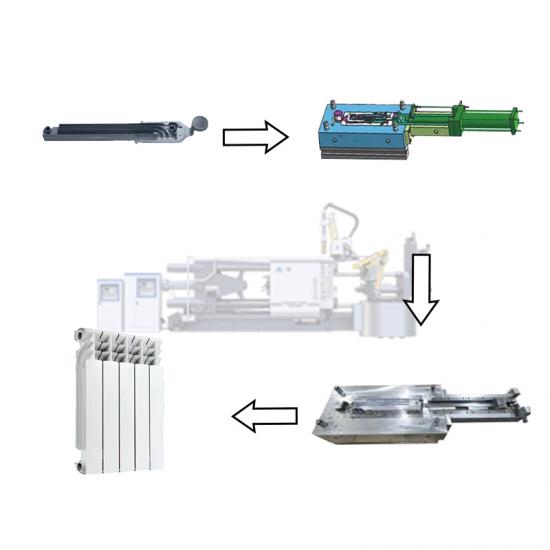

The production of radiators involves multiple processes and steps, and the specific production process may vary

depending on the manufacturer and product type. The following are the main steps of a typical radiator production

process:

1. Raw material preparation: The first step in producing radiators is to prepare the necessary raw materials.Common raw materials include cast iron, aluminum alloy, etc. These materials undergo strict quality inspection

to ensure compliance with product design and quality standards.

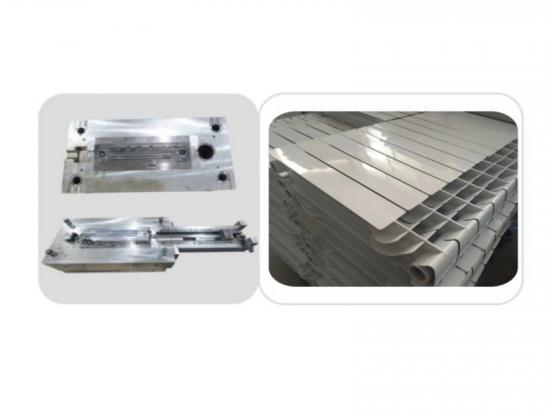

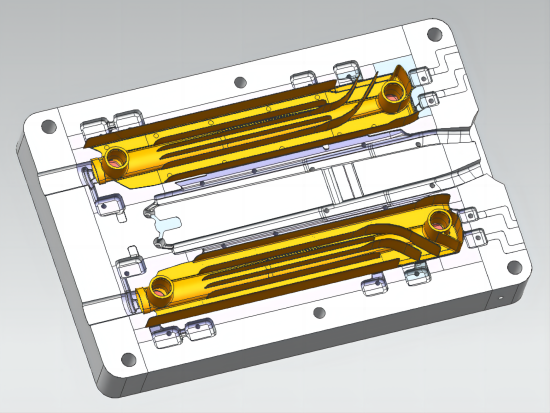

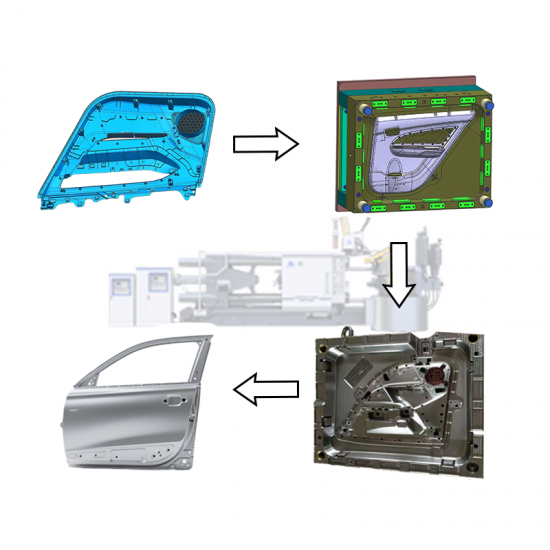

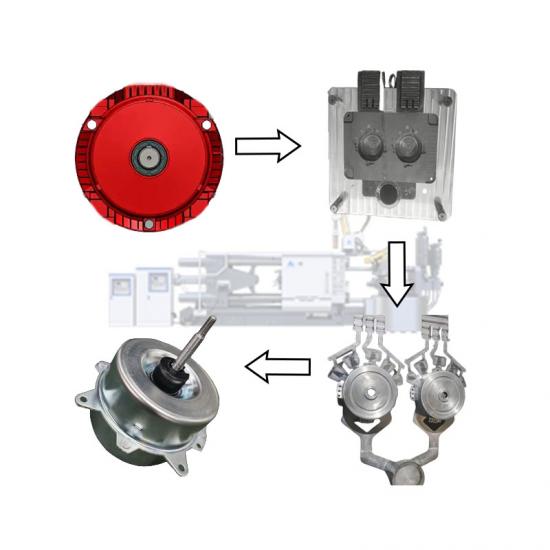

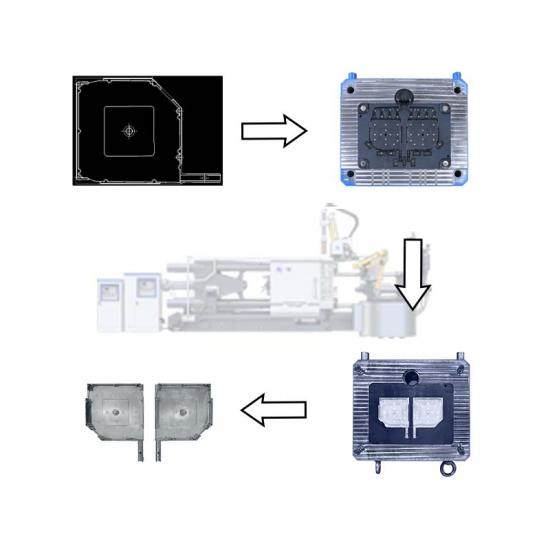

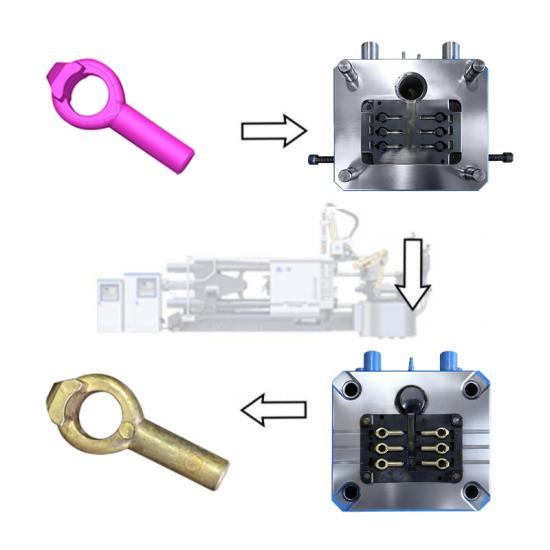

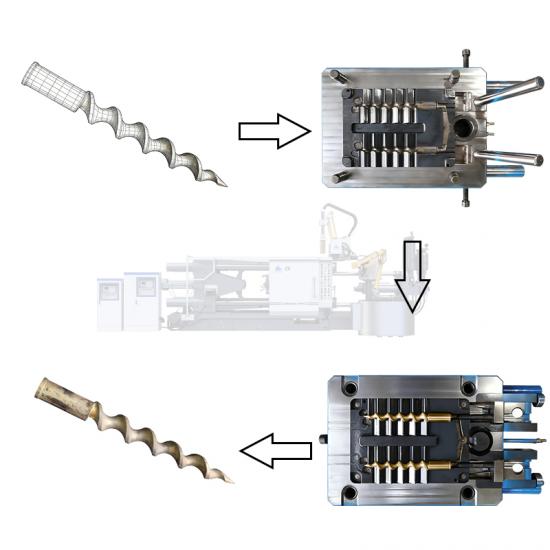

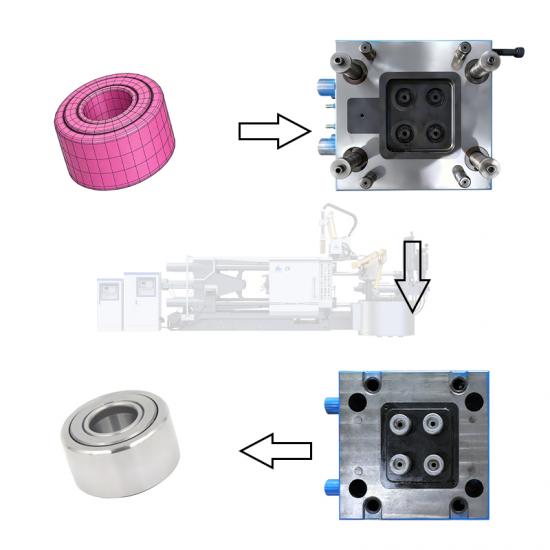

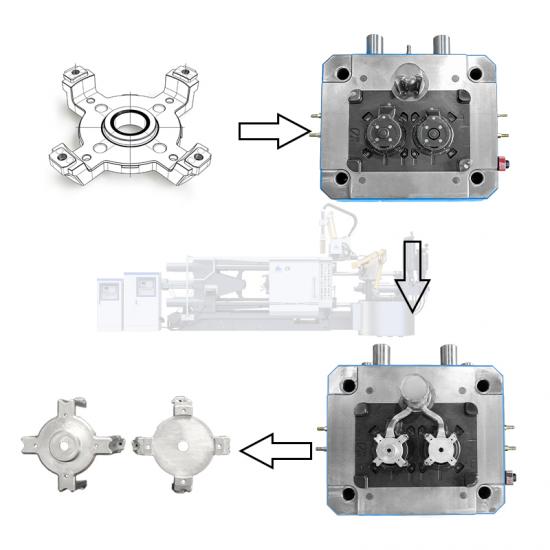

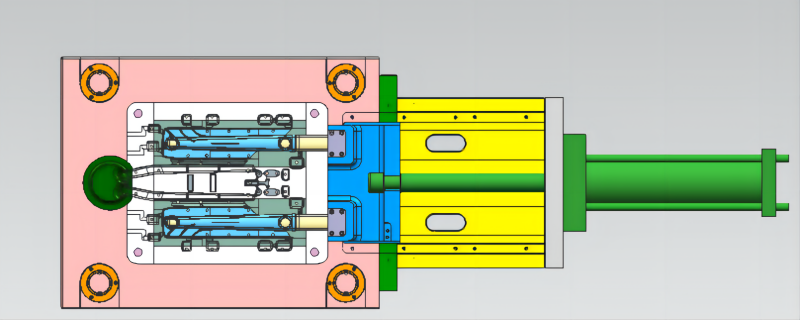

2. Mold manufacturing: Manufacturing radiators typically requires the use of molds to ensure product consistencyand accuracy. Molds are usually made based on product design and can be metal molds or other suitable materials.

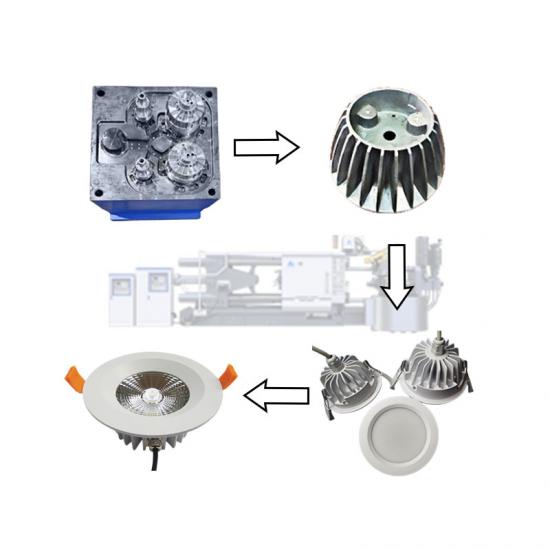

3. Aluminum die-casting process: Aluminum die-casting process is a key step in producing cast iron radiators.

In this process, heated metal (cast iron or other alloys) is injected into the mold to solidify and form in a specific

shape of the mold.

4. Processing and shaping: Once the basic shape of the radiator is formed, it is necessary to process and shape

it to ensure the accuracy and surface quality of the product. This may include cutting, grinding, and other.

Mechanical processing steps:

1. Raw material preparation: The first step in producing radiators is to prepare the necessary raw materials.

Common raw materials include cast iron, aluminum alloy, etc. These materials undergo strict quality inspection

to ensure compliance with product design and quality standards.

2. Mold manufacturing: Manufacturing radiators typically requires the use of molds to ensure product consistencyand accuracy. Molds are usually made based on product design and can be metal molds or other suitable materials.

3. Aluminum die-casting process: Aluminum die-casting process is a key step in producing cast iron radiators.

In this process, heated metal (cast iron or other alloys) is injected into the mold to solidify and form in a specific

shape of the mold.

4. Processing and shaping: Once the basic shape of the radiator is formed, it is necessary to process and shape

it to ensure the accuracy and surface quality of the product. This may include cutting, grinding, and other

mechanical processing steps.

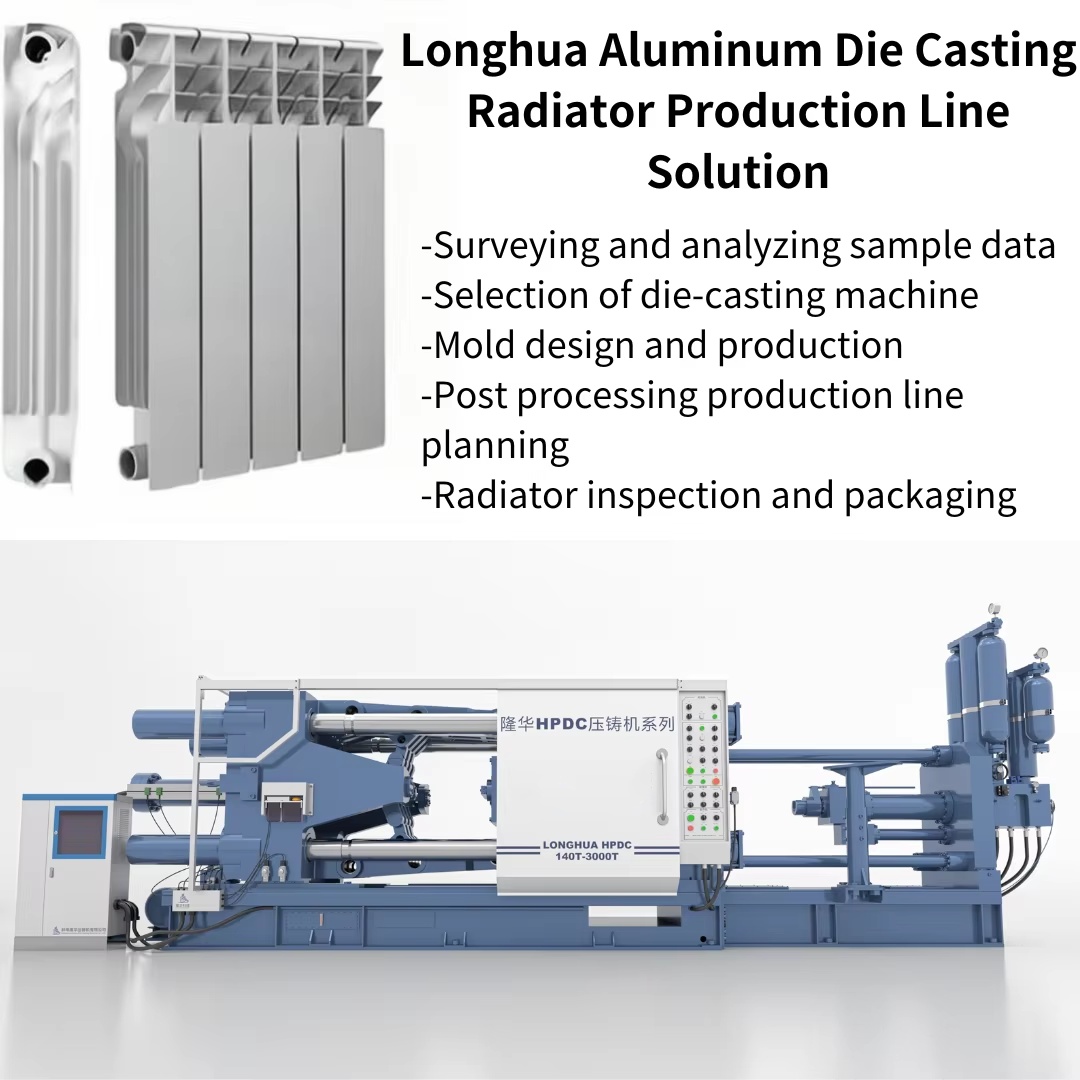

In addition to the above steps, there are also processes such as heat treatment and packaging. Our company

can customize all subsequent processing and equipment for you and provide you with a turnkey procurement plan.

|

Product Type |

LH-RADIATOR-PRODUCTION LINE |

|

Product name |

Panel Radiator Automatic Production Line |

|

Usage |

Aluminum die-casting radiators |

|

Application |

Die casting |

|

Function |

Stable |

|

Condition |

New |

|

Final product |

Radiator |

|

Material |

Stainless Steel Material |

|

Capacity |

1000 Pcs/8h |

ABOUT US

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.

It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry for several

decades.The company focuses on research,development,production,and sales of various types of die casting

machines.The company's product range covers cold chamber die-casting machines,die-casting manipulators,

industrial robots and peripheral equipment of die-casting machines to meet the needs of different customers.