Circular motor housing mold

Circular motor housing die casting process

Preliminary preparation:

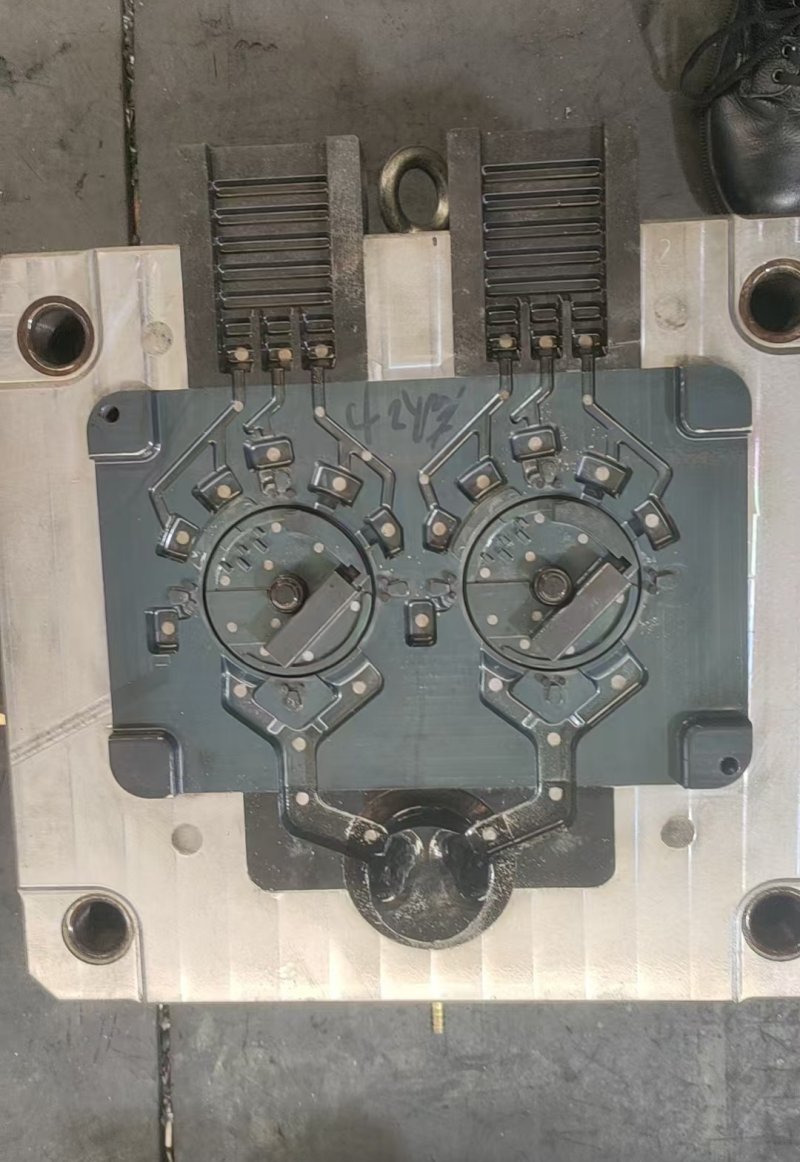

Analyze the structure of the motor housing, including material selection (such as AlSi10Mg) and size determination (such as 393mm×123mm×312mm).

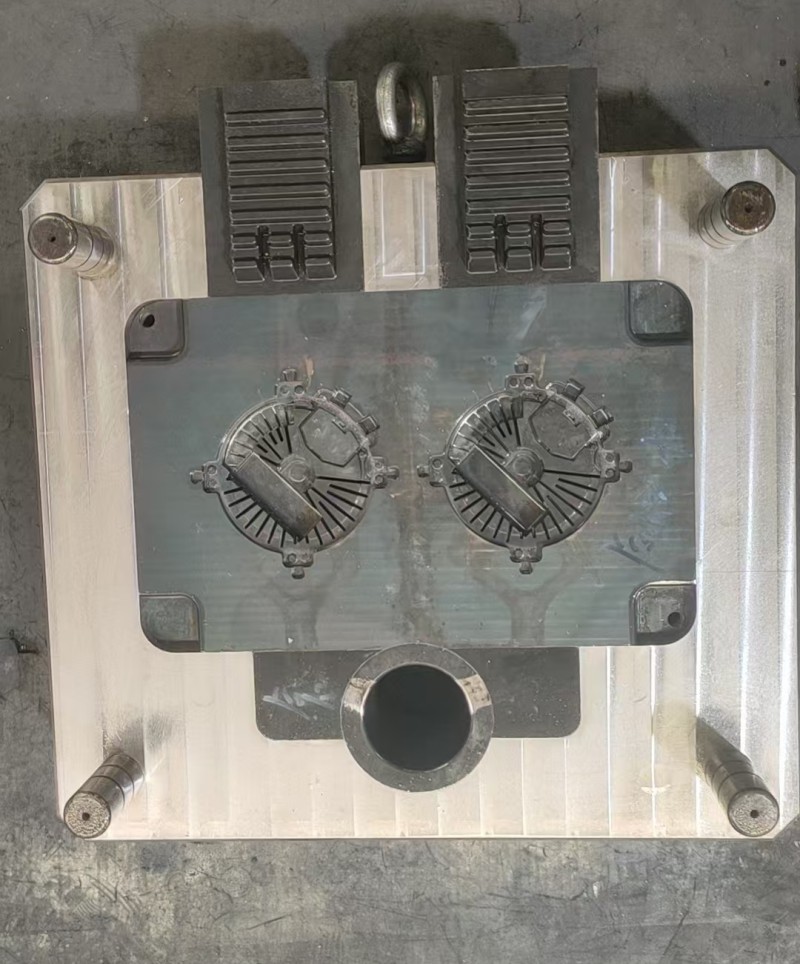

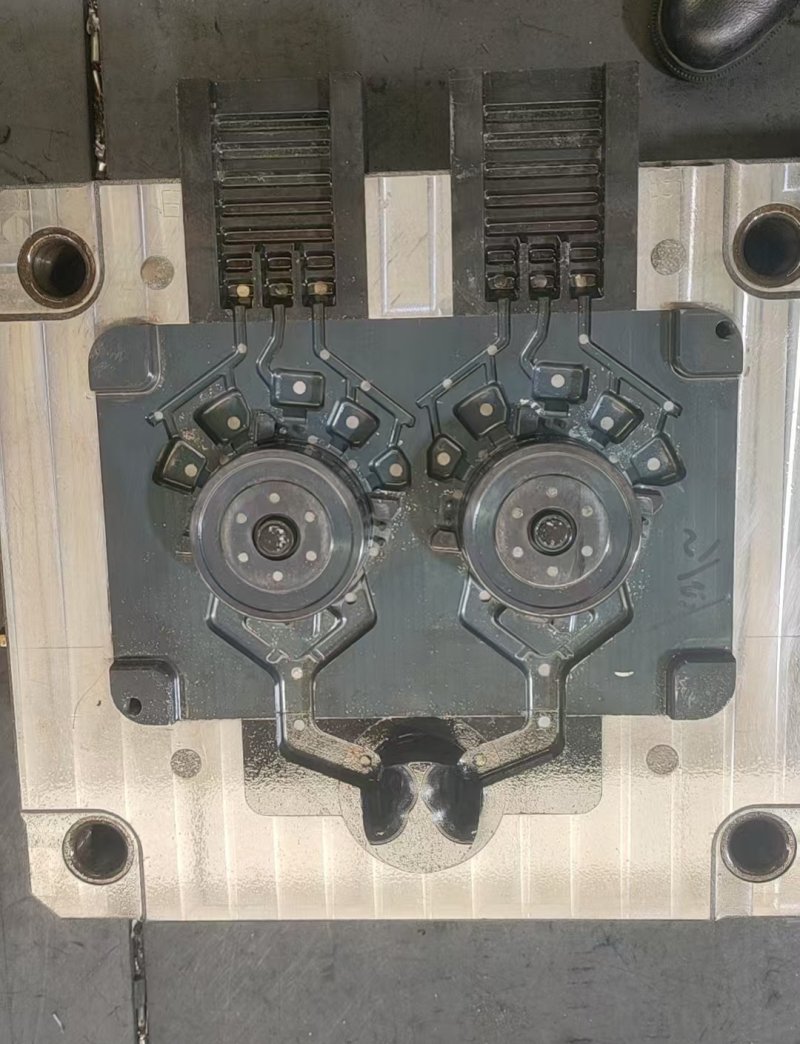

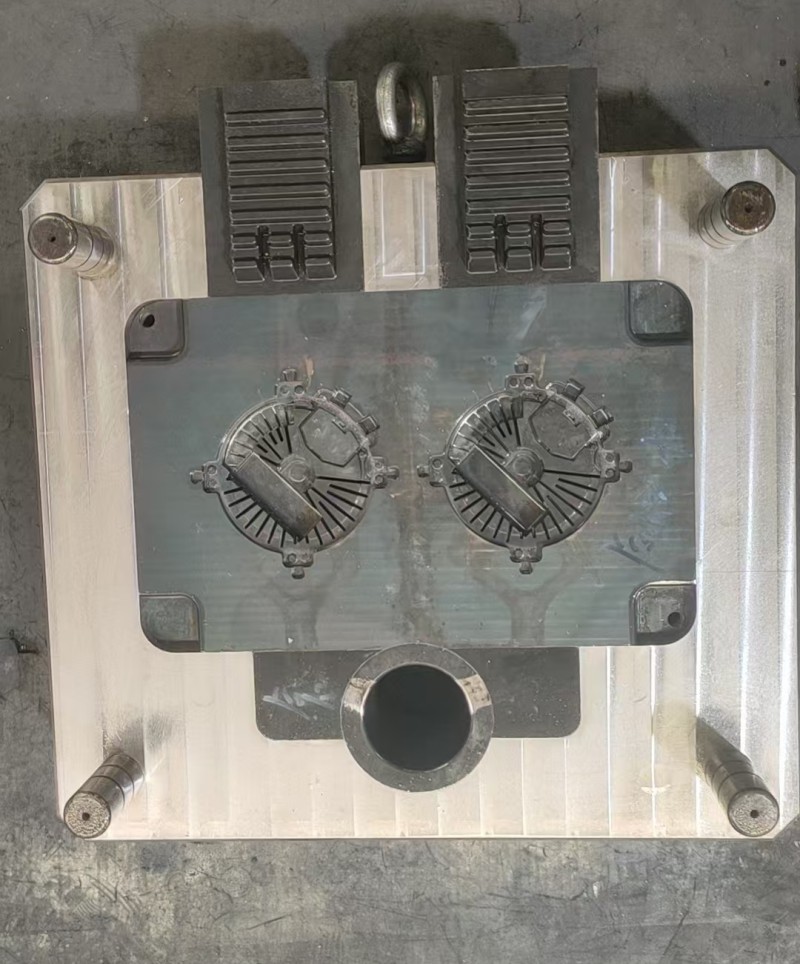

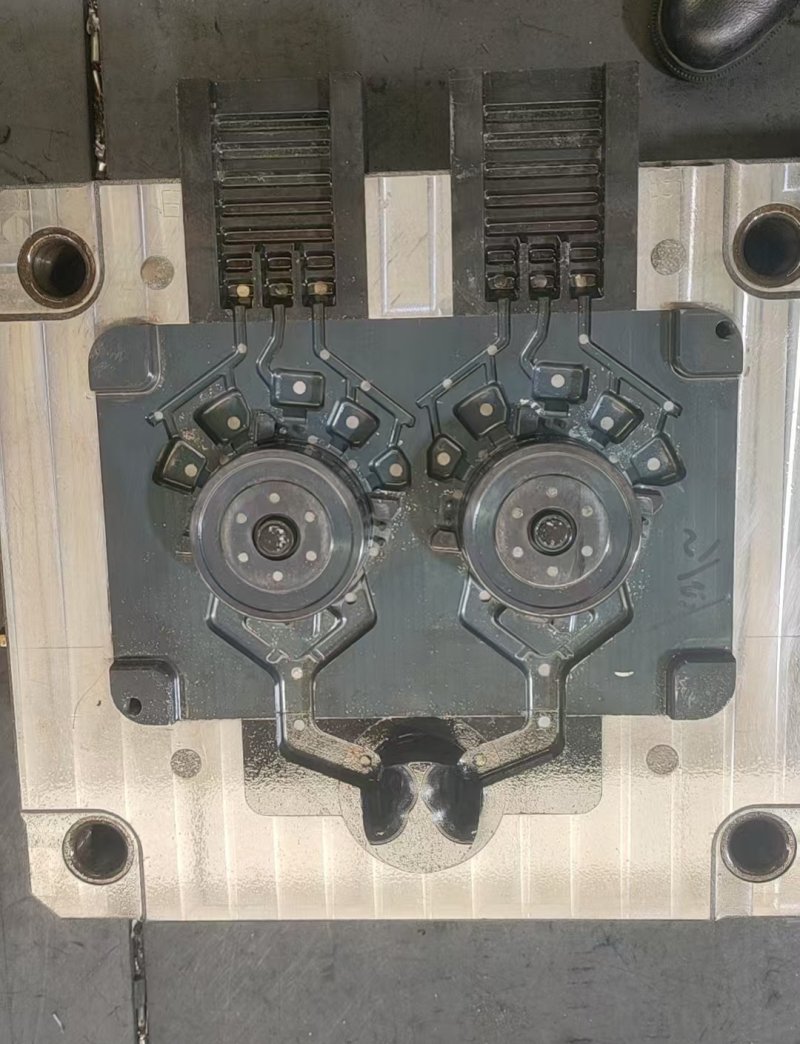

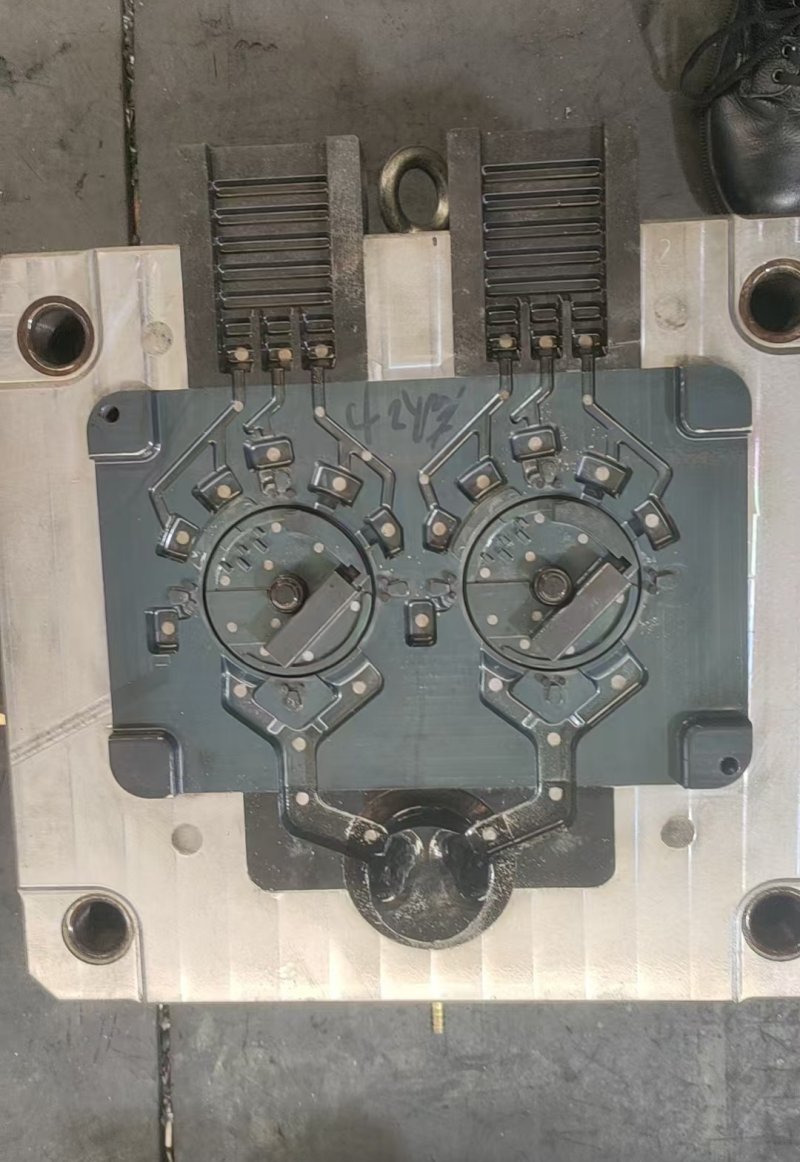

Design the die casting mold and optimize the pouring and overflow system through mold flow simulation analysis software.

Die casting steps:

Melting metal: Melt aluminum or other alloy materials and prepare for die casting.

Die casting: Use a die casting machine to inject molten metal into the mold, and use high pressure to fill the mold cavity with metal to form the shape of the motor housing.

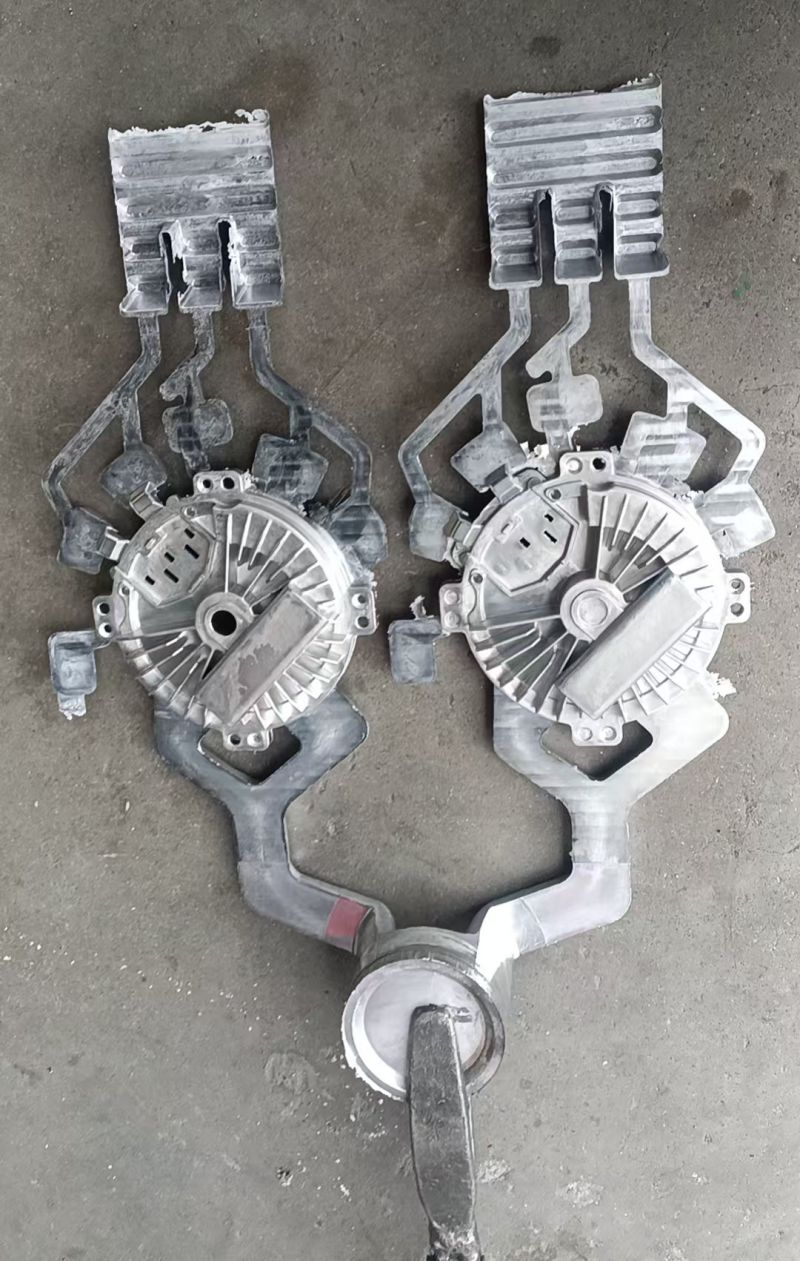

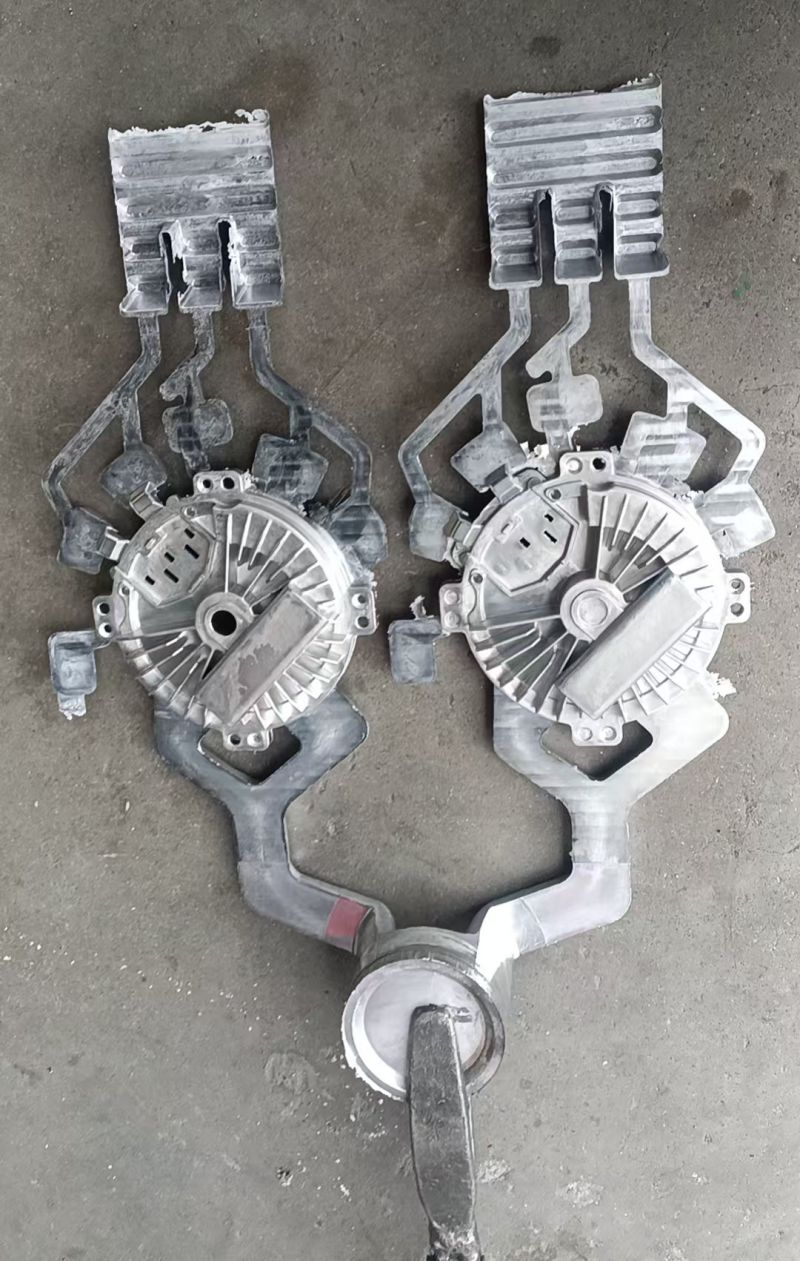

Demolding and post-processing: After the metal cools and solidifies, open the mold, take out the motor housing, and perform necessary post-processing, such as cleaning and trimming.

Product Origin:

Anhui ,ChinaItem NO.:

LH-SMShipping Port:

LiangyungangLead Time:

45daysPayment:

T/T