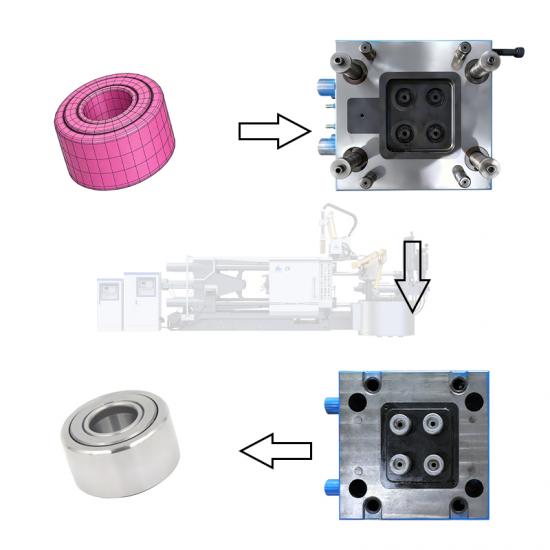

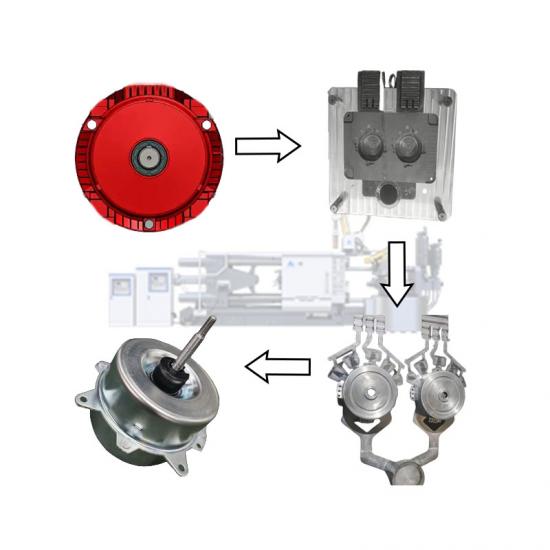

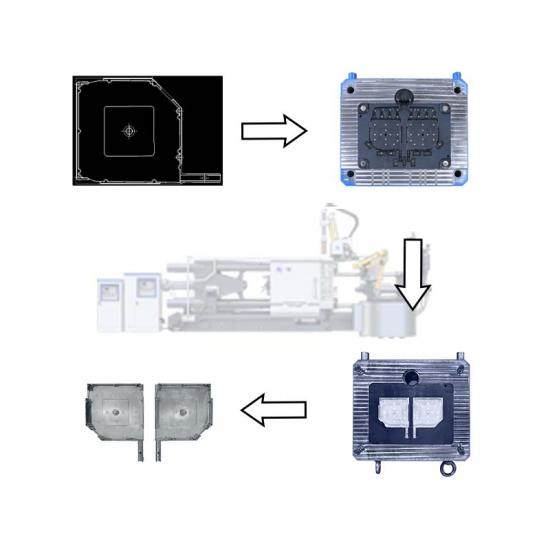

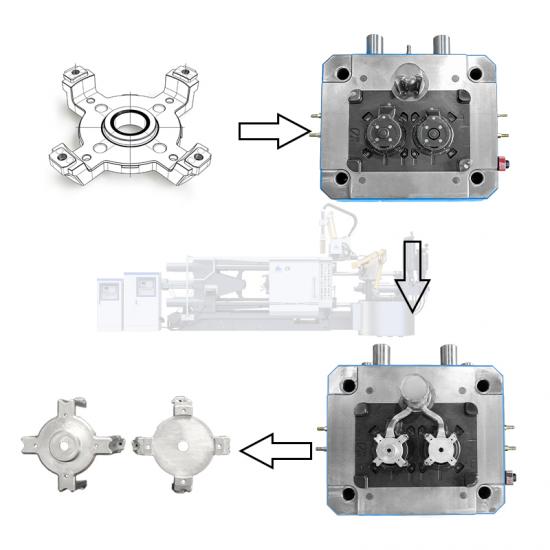

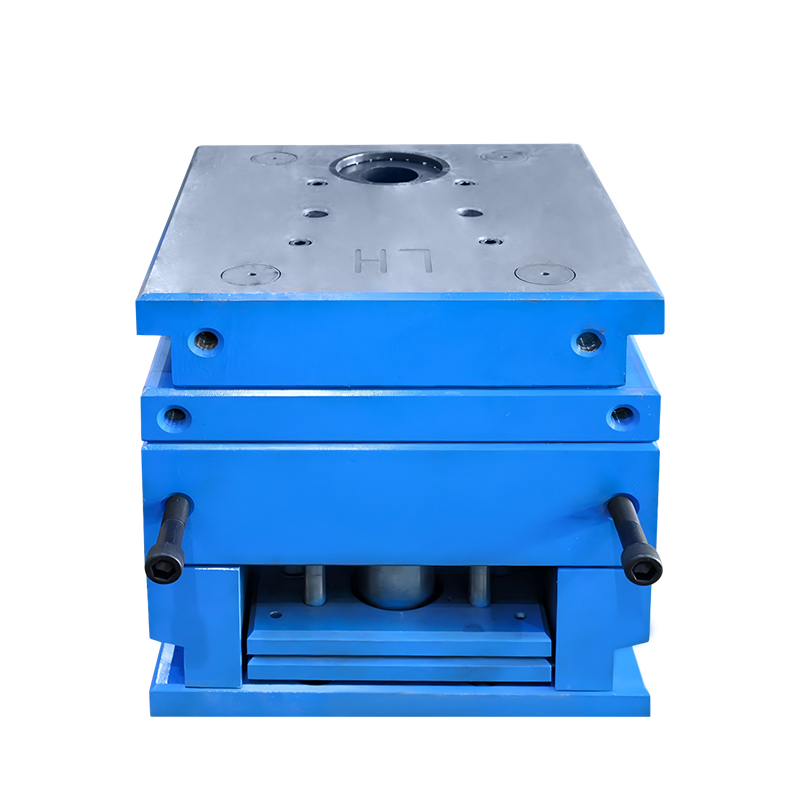

| Product Name | Longhua - Rotor Mold |

| Application | For die-casting rotors |

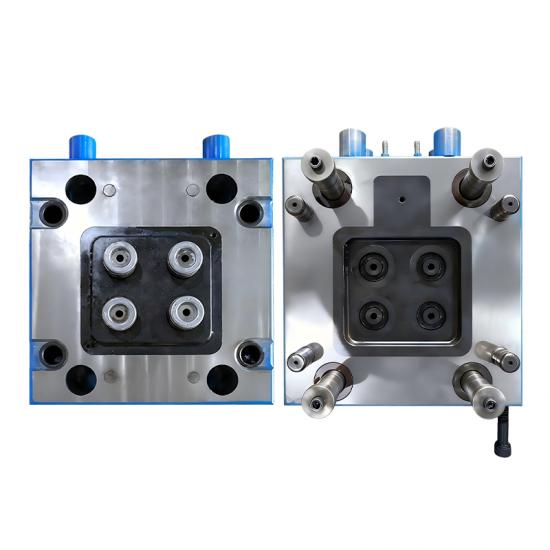

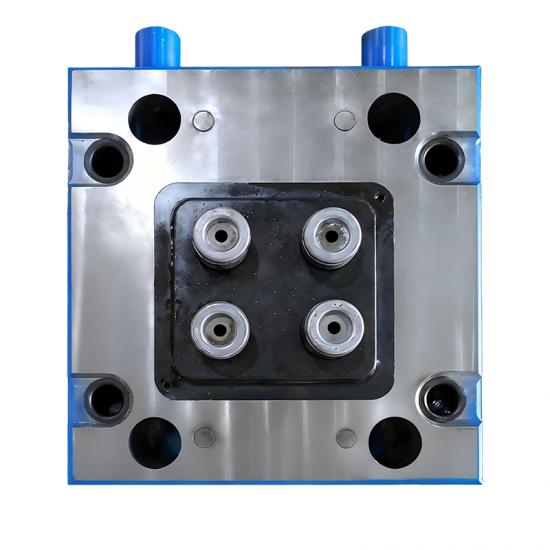

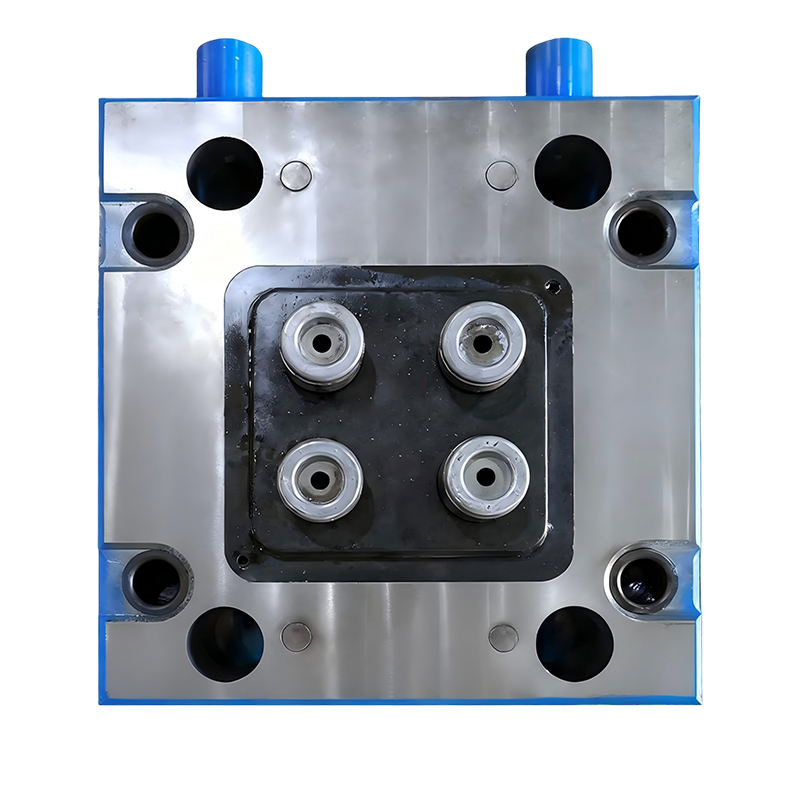

| Cavity Count | 4 cavities per cycle |

| Mold Material | Steel |

| Final Product | Rotor |

| Advantages | High efficiency, high precision, pore-free |

| Performance Feature | Stable performance |

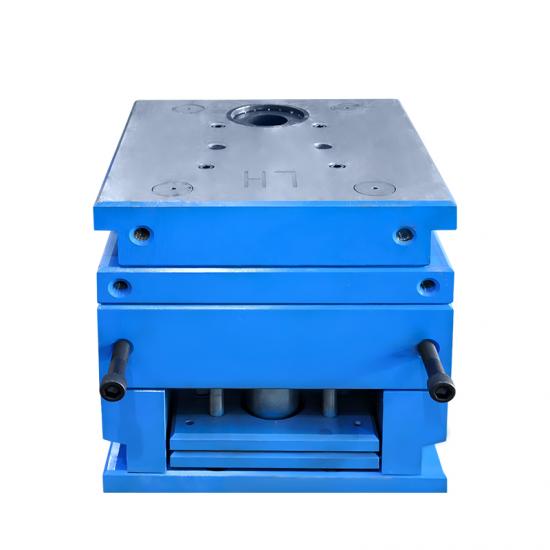

| Production Capacity | 1,000 cycles per 8 hours |

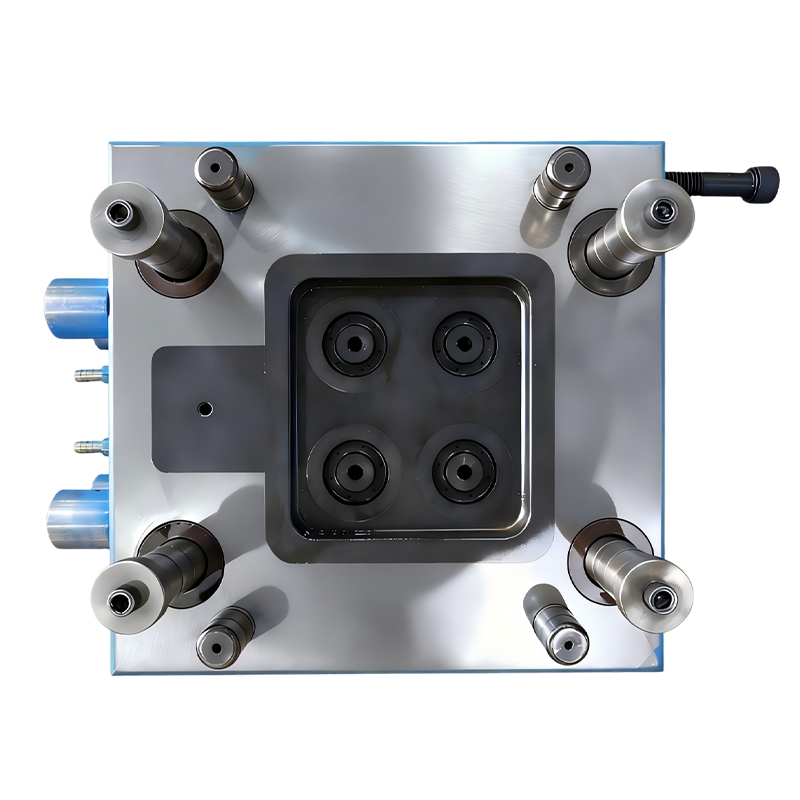

This special precision die·casting mold for rotor bearings is designed to solve common industry pain points, including poor coaxiality between rotors and bearing positions, unstable dimensional accuracy, uneven wall thickness, easy scratching, difficult demolding, and poor batch consistency.

By optimizing the gating system, balanced cooling, ejection structure, and coaxial positioning of the cavity, it effectively improves the following aspects:

· Stable dimensional accuracy and coaxiality

· High surface finish, no scratches or shrinkage holes

· Short molding cycle and high production efficiency

· Long mold service life and significantly improved yield rate

· Reduced post·processing costs, suitable for mass stable production

Application Fields

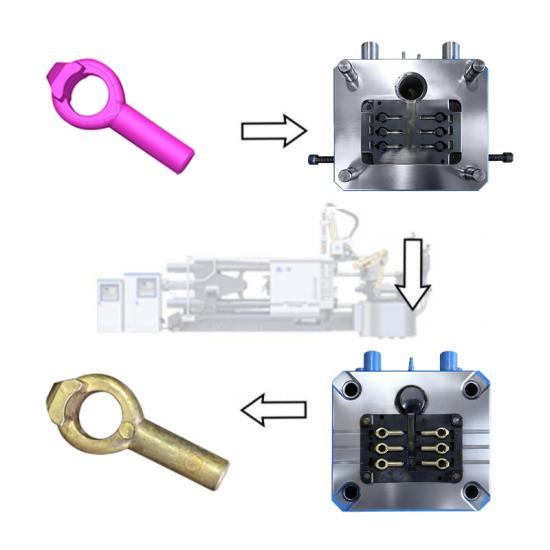

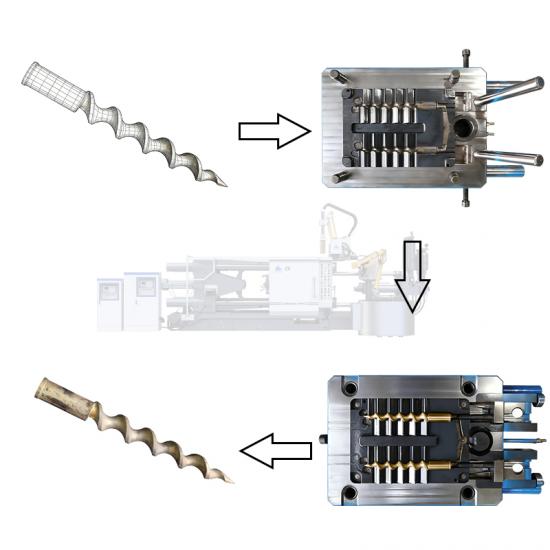

It is widely used in the production of precision die·casting parts such as motor rotors, water pump rotors, fan rotors, electric tool rotors, bearing seats, bearing end covers, and small precision transmission components.

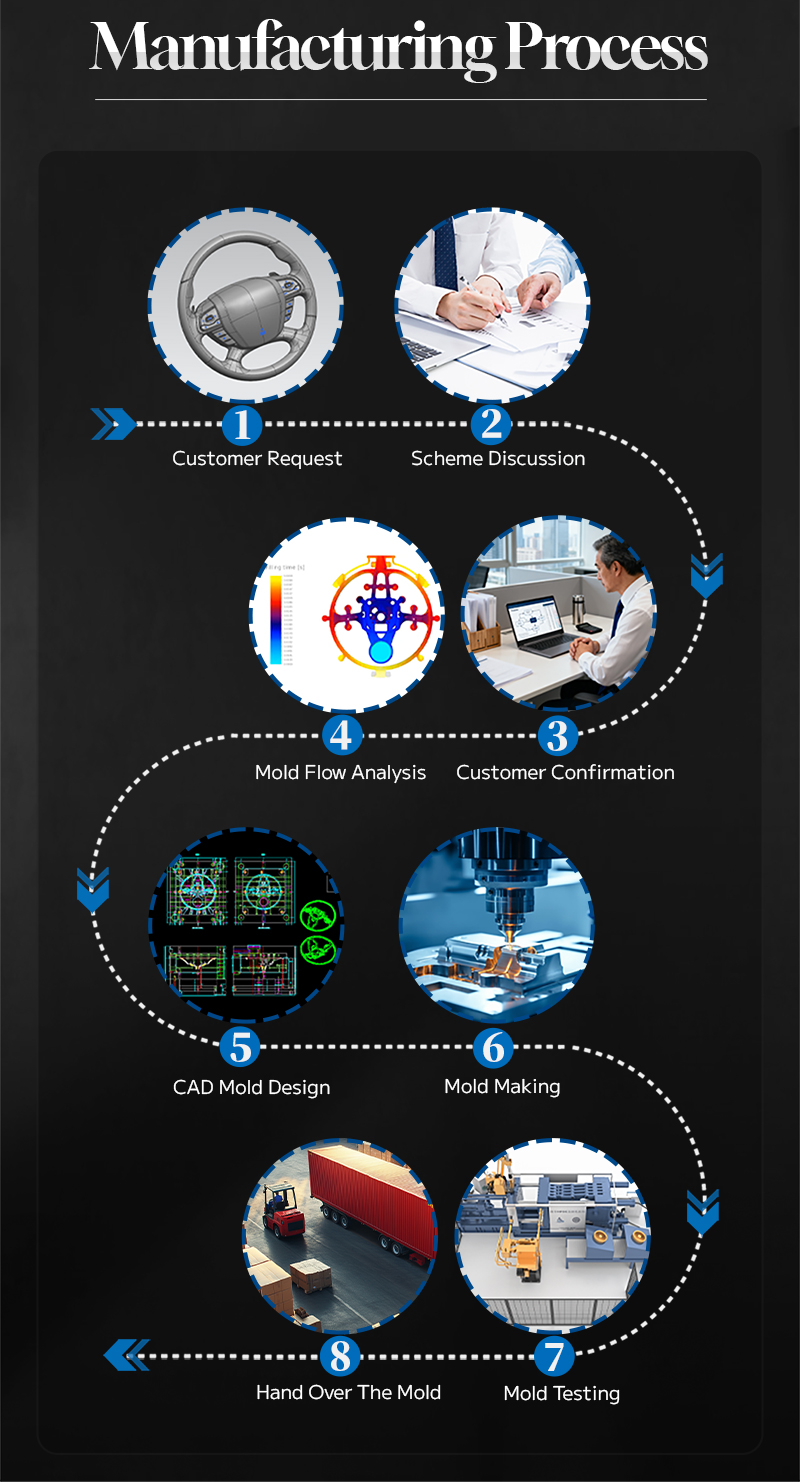

How to Identify a High-Quality Mold Supplier

· Possess specialized design experience in precision die·casting molds for rotors/bearings and be familiar with coaxiality control.

· Able to provide runner analysis, cooling solutions, precision commitments, and mold service life guarantees.

· Adopt high·quality mold steel and standard accessories to ensure processing accuracy.

· Provide one·stop services including mold testing, machine adjustment, after·sales maintenance, and technical support.

· Have mature practical cases of motor/rotor/bearing molds and a stable customer reputation.

1. Who are we?

We are based in Anhui, China, Longhua was founded in 1950 and has specialized in the R&D and manufacturing of die-casting machines since 1982.We now have 44 years of history in R&D and casting.To date, our products have been exported to 43 countries.

2. How can we guarantee quality?

Always final Inspection before shipment;

3. What can you buy from us?

Die casting machines, die casting machine robots, die casting machine parts and consumables, moulds, melting furnaces and other peripheral equipment.

4. Why should you buy from us not from other suppliers?

Longhua Die Casting Machine has 44 years of production experience, and cooperate with the Chinese Academy of Science and Technology, you know that China's space shuttles are cooperating with the Chinese Academy of Science and Technology.

5. What services can we provide?

Accepted Delivery Terms: FOB/EXW;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,Cash;

Language Spoken:English,Chinese