How does cold chamber die casting machine work?

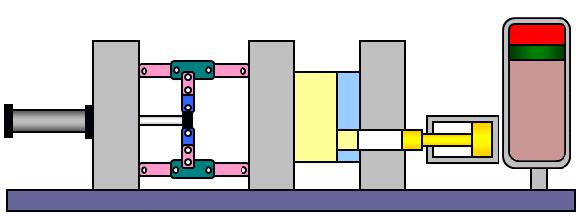

(The working procedure of cold chamber die casting machine)

Die casting is a manufacturing process that can produce geometrically complex metal parts through the use of reusable molds, called dies. The die casting process involves the use of a furnace, metal, die casting machine, and die. The metal, typically a non-ferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die casting machine. There are two main types of die casting machines - hot chamber machines (used for alloys with low melting temperatures, such as zinc) and cold chamber machines (used for alloys with high melting temperatures, such as aluminum).

Now let's talk about the working process of cold chamber die casting machine。

Cold chamber high pressure die casting technology is ideal for production of a diverse range of aluminium and magnesium automotive castings such as engine blocks, gearbox casings, oil sumps, engine mounts and structural parts like cross-car beams.

High pressure die casting technology can produce very large light alloy parts, in high volumes and great speeds.These machines deliver light alloy parts with high precision, superior surface finish, excellent uniformity and optimum mechanical properties.The high pressure die casting process can also produce components with thin walls and "co-cast” parts with different types of inserts, such as screws and liners, that then become an integral part of the product itself.It is widely used in other sectors to manufacture components in applications that range from the simplest – a lighting component – to the most demanding, such as aerospace engine parts.

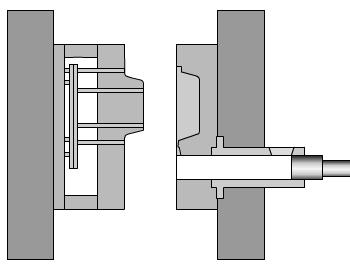

In a high pressure die casting process, molten metal or metal alloy is injected at high speed and high pressure into the mould.Horizontal high pressure die casting machines ensure the die closes completely. These are rated by how much closing force they can apply。

In cold chamber process the metal is first melted in a separate furnace, then poured into the cold chamber die casting machine and injected into the mould. The extra material is used to force additional metal into the die cavity to compensate for shrinkage, which takes place during solidification.

Bengbu Longhua die casting machine company offers a wide range of cold chamber high pressure die casting machines.