During the manufacturing process of die castings, pitting (also called pitting) is a common surface defect that affects the appearance and quality of the part. Pockmarks usually appear as many small bumps or depressions on the surface, similar to pitting. The following are some common causes of pitting problems in die castings and their corresponding solutions:

1. Gases and bubbles of metallic liquid:

Cause of the problem: The gas and bubbles in the metal liquid were not completely eliminated during the filling process, resulting in pitting on the surface of the die casting.

Solution: Optimize the treatment process of the metal liquid, take measures such as vacuum evacuation or inert gas treatment to reduce the gas content, optimize the pouring system and pouring parameters to ensure that the filling of the metal liquid is uniform and stable, and reduce gas trapping.

2. Improper temperature control of metal liquid:

Cause of the problem: If the temperature of the metal liquid is too high or too low, it may lead to poor fluidity of the metal liquid during the filling process, and it is easy to form pits.

Solution: Strictly control the pouring temperature of the metal liquid to ensure that it is poured within a suitable temperature range and avoid the temperature being too high or too low.

3. Mold surface problems:

Cause of the problem: There are problems such as wear, oxidation or contamination on the mold surface, which causes the metal liquid to easily flow unevenly during the pouring process and form pitted surfaces.

Solution: Clean and maintain the mold regularly to ensure the mold surface is smooth and clean, and use appropriate coatings or paints to prevent oxidation or contamination of the mold surface.

4. The flow of metal liquid is not smooth:

Cause of the problem: The metal liquid is hindered or flows unevenly during the filling process, resulting in insufficient filling and prone to pitting.

Solution: Optimize the design of the pouring system, reduce the resistance of the metal liquid during the flow process, increase the pouring port or change the pouring direction to promote the flow of metal.

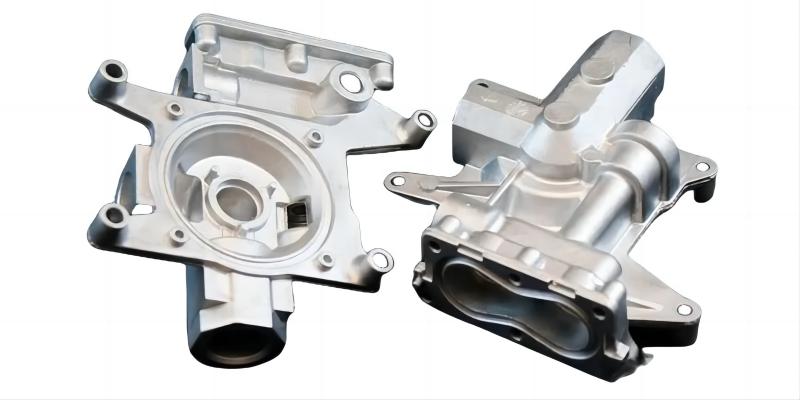

Longhua has extensive experience in the field of designing high-precision molds, which can effectively prevent and reduce pitting problems in die castings and improve the surface quality and appearance of die castings.