A servomechanism, also known as a follow-up system, is a feedback control system designed to accurately follow or reproduce a process. Servo system an automatic control system that enables the position, orientation, state and other output controlled quantities of the object to follow arbitrary changes in the input target (or a given value). Its main task is to magnify, transform and control the power according to the requirements of the control command, so that the torque, speed and position control of the output of the drive device is very flexible and convenient. Servo system in many cases, the amount of points to be controlled (system) of the output is the mechanical displacement or displacement velocity and acceleration feedback control system, its role is to make the output of the mechanical displacement (or Angle) to accurately track the input displacement (or Angle), its structure and other forms of feedback control system there is no difference in principle. Servo system was initially used in the national defense industry, such as gun control, ship, aircraft autopilot, missile launch, etc., and then gradually promoted to many sectors of the national economy, such as automatic die-casting production line, wireless tracking control, etc.

First, the main role

1. Control high-power load with low-power instruction signal;

2. In the absence of mechanical connection, the input shaft controls the output shaft located in the distance to achieve remote synchronous transmission;

3, make the output mechanical displacement accurately track electrical signals, such as recording and indicating instruments.

Ii. Development history

Servo is a shortening of ServoMechanism, which comes from Greece and means slave. As the name suggests, ServoMechanism refers to the system following external instructions to perform the desired motion. The motion factors include position, speed and torque. Reviewing the development history of servo system, from the earliest hydraulic and pneumatic to the current electrification, servo system composed of servo motor, feedback device and controller has gone through nearly 50 years.

Nowadays, with the continuous maturity of technology, AC servo motor technology with its excellent cost performance, gradually replace DC motor to become the dominant motor servo system. The mature technology of AC servo system also makes the market show a rapid diversified development, and become one of the supporting technologies of industrial automation.

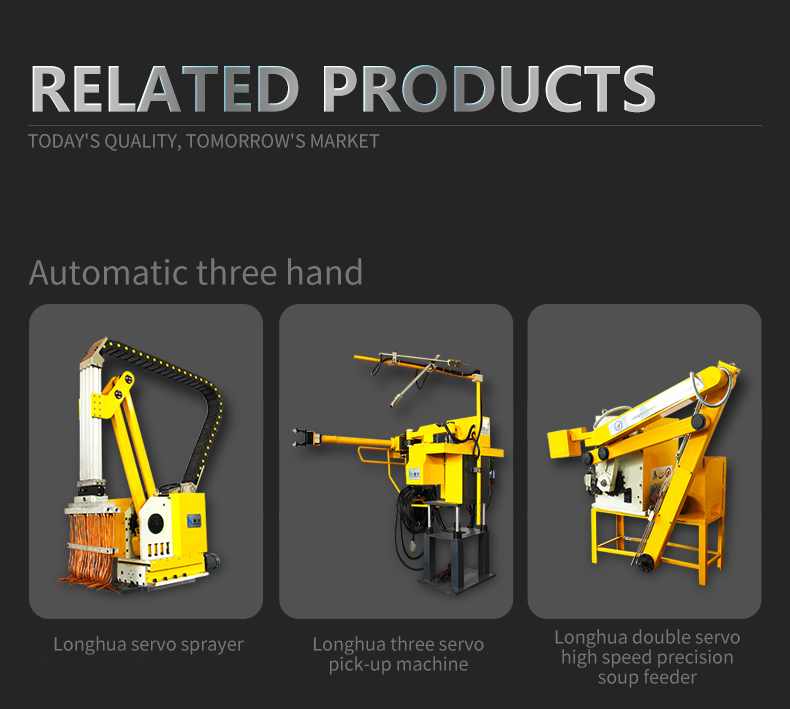

3. Die-casting machine equipped with servo robot