According to data released by the China Foundry Association, driven by the rapid growth of new energy vehicles and the development of light-weight vehicles, the overall output of automotive aluminum alloy die-casting in my country has shown a fluctuating upward trend in recent years, and large-scale integrated die-casting has triggered an unstoppable development trend in the global die-casting industry.

The 2024 Shanghai International Nonferrous Diecasting Exhibition (CID & CNF) with the theme of "New Energy Vehicle Development Builds a New Global Pattern of Die Casting" was grandly opened, and 900T-16000T super-large automotive die-casting parts made their first splendid appearance.

The following is a display of die-casting parts of super-large automotive casting manufacturing equipment 900T-16000T:

Integrated rear base plate large casting (9000T die casting machine)

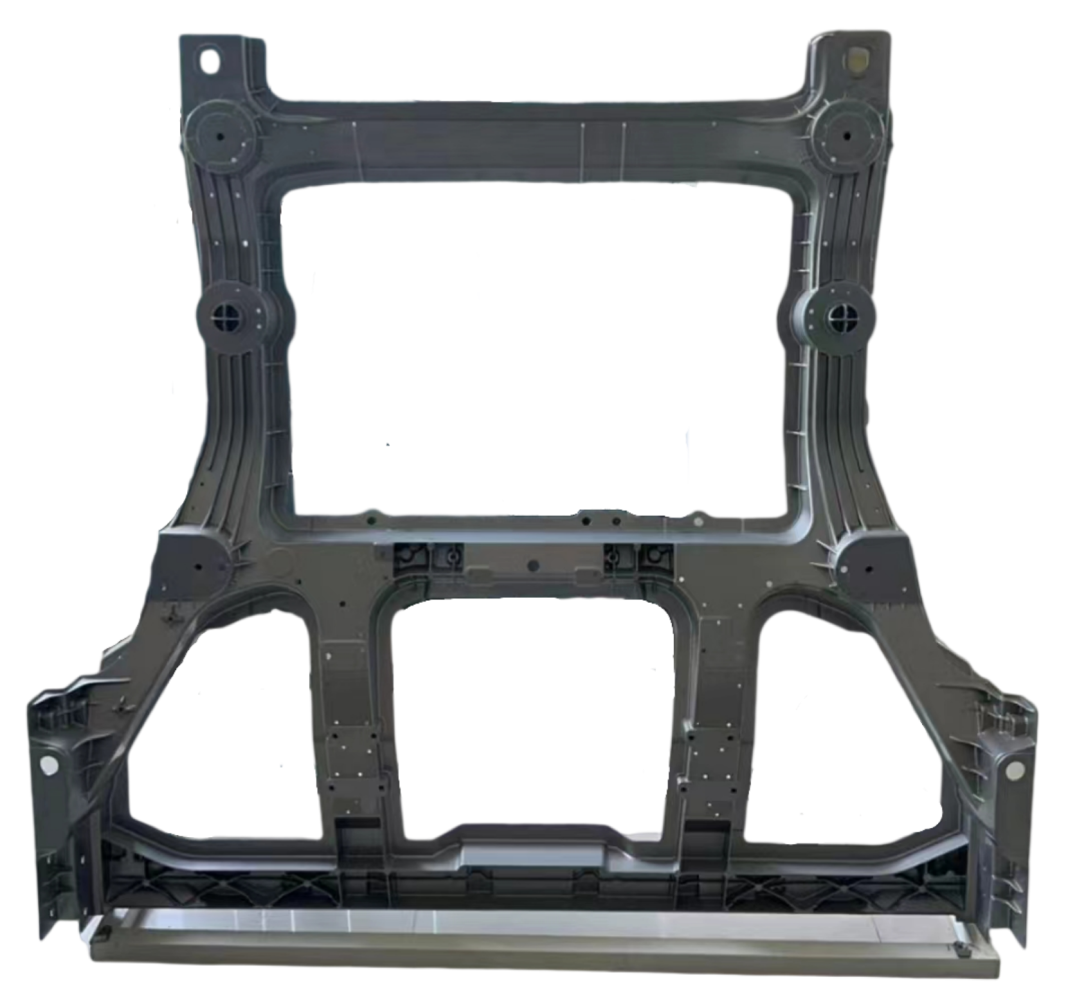

Integrated die-casting front cabin (9000T die casting machine)

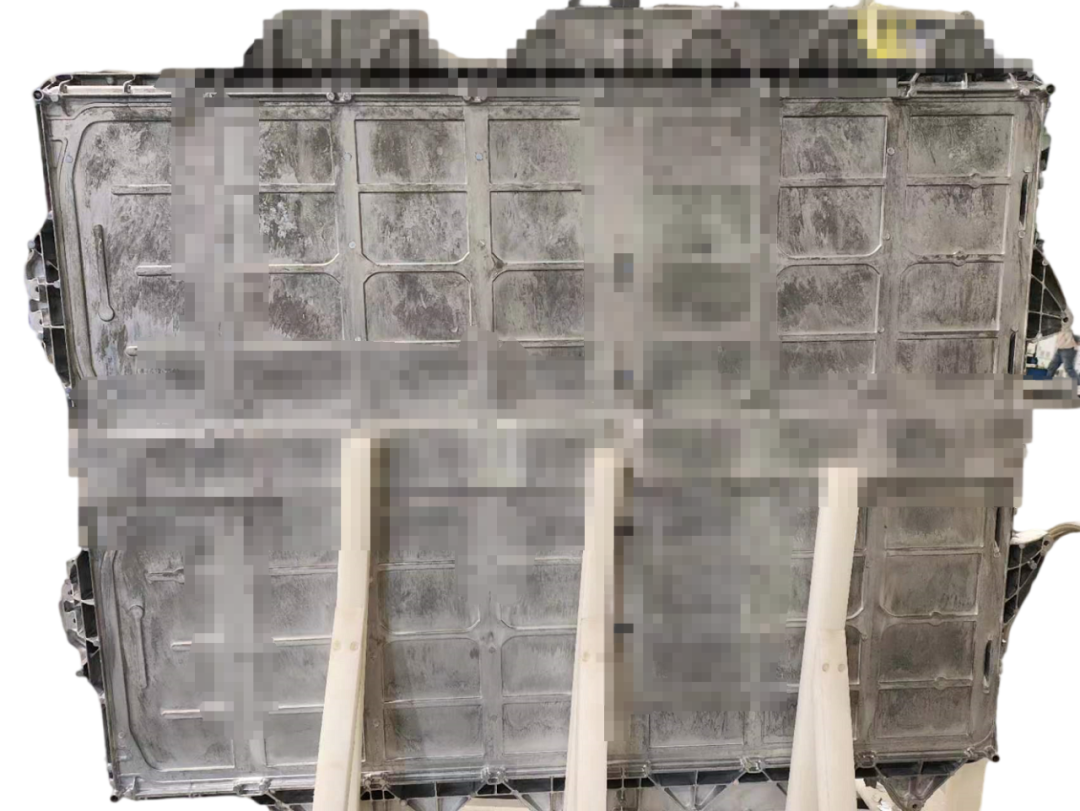

Double-shot battery body integrated die-casting overall chassis (13000T double-shot die-casting island die casting machine)

Battery tray (16000T die casting machine)

The above products show that with the continuous advancement of die casting technology, extra-large die-castings will play a key role in promoting the light-weighting of new energy vehicles, improving energy efficiency and reducing costs. In the future, large-scale integrated die-casting technology will be the key technical direction for leading companies in the industry to deploy, and will contribute more to the development of the global new energy vehicle industry!