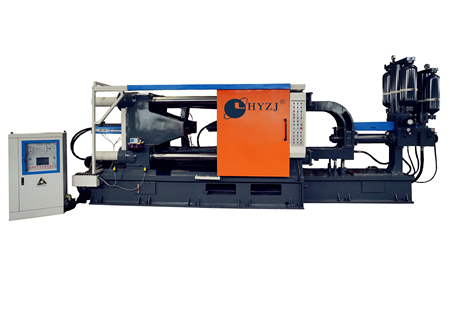

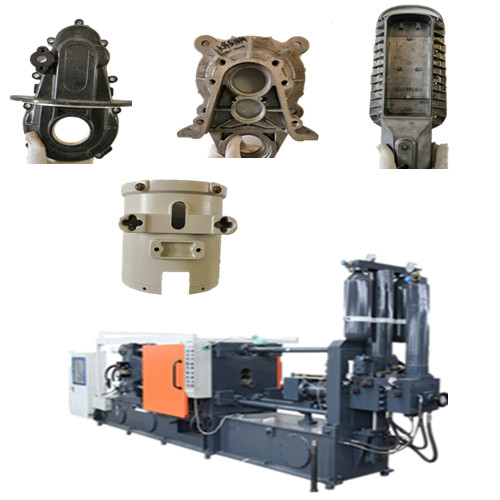

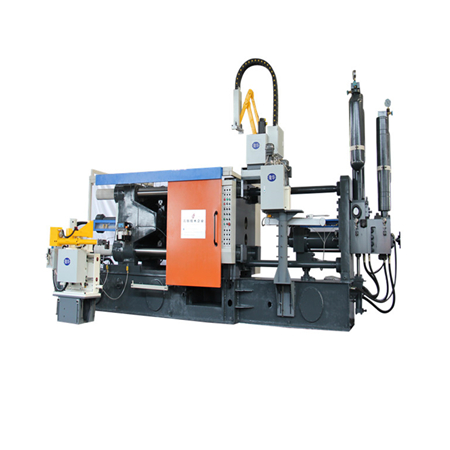

Today, Longhua Die Casting Machine introduces some operation requirements of aluminum alloy die casting machine, let's take a look together!

1. Strictly monitor the die casting process

The temperature of the molten aluminum in the holding furnace should be controlled at ± 3 ° C in order to stabilize the stirring temperature. The temperature after stirring must be adjusted according to the chemical composition of each furnace to ensure that the solid phase rate is stable at ± 2%. The temperature of the mold must be checked and controlled so that the alloy can be smoothly filled and orderly solidified. It is necessary to rationally formulate and timely adjust the process parameters of the die casting machine, and make regular inspections on the die casting to ensure the quality of the die casting.

2.Precautions for release agent spraying operation

Pay attention to how much paint is applied to the release agent to avoid too much paint, too little or missing paint. More paint can be sprayed on the parts that are difficult to be demolded, and less paint can be sprayed on the parts that are easy to demold. When spraying paint, use a spray gun to move from top to bottom in layers to let the water accumulated in the cavity flow from top to bottom and blow excess water out of the cavity. The cavity is easily adhered to the mold, first spraying at a short distance to cool down, and then spraying at a longer distance to form a coating film. Do not spray too close to prevent paint water from flowing in the cavity. After spraying, use air to blow away the excess and accumulated paint in the cavity, especially pay attention to the paint in deep cavities or dead corners to prevent the water from vaporizing into a large amount of gas after the heat, making the casting appear pores. , Under casting, cold insulation, blistering, this has a very important role in eliminating the occurrence of pores in the casting.

3.Precautions for hot film of die casting machine

After using the mold temperature machine hot mold, when starting the die casting hot mold, you can use the liquid alloy low speed die casting hot mold 5-10 mold, and then use the normal semi-solid alloy and semi-solid die casting parameters for die casting production, which can protect the mold, It can also prevent flashing and flying materials.