The die temperature machine, also known as a die thermal control unit or die heater/chiller, plays a crucial role in the die casting process. Its main functions and benefits include:

1. Temperature control: The die temperature machine is responsible for precisely controlling and maintaining the temperature of the die or mold used in the die casting process. It can heat or cool the die as needed to achieve the desired temperature range for optimal casting conditions. Controlling the die temperature is essential for ensuring consistent quality, dimensional accuracy, and mechanical properties of the castings.

2. Thermal balance: The die temperature machine helps to achieve thermal balance throughout the die. By evenly distributing heat or cooling within the die, it reduces temperature variations and gradients that can lead to thermal stresses, warpage, or defects in the castings. Maintaining thermal balance ensures uniform filling and solidification of the molten metal, resulting in better casting quality.

3. Cycle time reduction: Proper die temperature control with the die temperature machine can significantly reduce the cycle time in the die casting process. By preheating the die to the desired temperature, it allows for faster and more efficient mold filling, solidification, and cooling of the castings. This shorter cycle time improves productivity and overall throughput.

4. Defect prevention: The die temperature machine helps to prevent defects in die castings. By controlling the die temperature, it minimizes the occurrence of surface defects such as porosity, cold shuts, and flash. It also helps to reduce internal defects like shrinkage and cracking by ensuring proper metal flow and solidification throughout the casting.

5. Energy efficiency: The die temperature machine optimizes energy consumption by efficiently heating or cooling the die. It minimizes energy waste by providing precise temperature control and minimizing heat loss from the die. This energy efficiency not only reduces operational costs but also contributes to a more sustainable and environmentally friendly die casting process.

In summary, the die temperature machine plays a critical role in die casting by controlling the die temperature, achieving thermal balance, reducing cycle time, preventing defects, and improving energy efficiency. It is an essential tool for ensuring high-quality castings and optimizing the overall die casting process.

When selecting a die temperature machine, several important factors should be considered. Here are some key aspects to consider during the selection process:

1. Temperature range: Determine the required temperature range based on the die casting materials and process requirements. Ensure that the selected die temperature machine can cover the necessary temperature range and provide the desired temperature control accuracy.

2. Heating and cooling capacity: Verify that the die temperature machine has sufficient heating and cooling capacity to rapidly reach and maintain the desired die temperature. Consider the time required for heating and cooling the die, as well as the rate of temperature change required for efficient die casting operations.

3. Temperature control accuracy: Check the temperature control accuracy of the die temperature machine. Precise temperature control is essential for maintaining consistent die temperature and ensuring quality castings. Look for a machine that offers a high level of temperature control accuracy and stability.

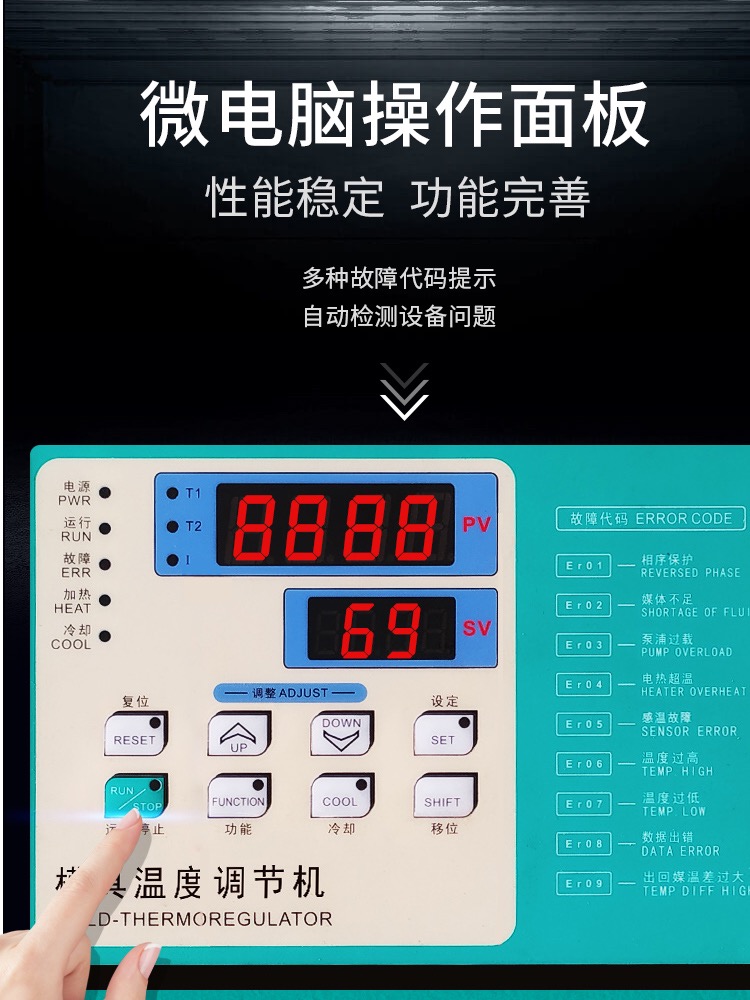

4. Control interface and functionality: Evaluate the control interface and functionality of the die temperature machine. An intuitive and user-friendly interface can simplify operation and monitoring. Look for features such as digital displays, programmable temperature profiles, and remote monitoring capabilities for enhanced control and convenience.

5. Safety features: Consider the safety features of the die temperature machine. Look for features like over-temperature protection, fault diagnostics, and emergency stop functions to ensure safe operation and minimize risks to personnel and equipment.

6. Reliability and durability: Select a die temperature machine from a reputable manufacturer known for producing reliable and durable equipment. Review customer reviews and seek recommendations to gauge the machine's reliability, longevity, and resistance to wear and tear.

7. Energy efficiency: Assess the energy efficiency of the die temperature machine. Look for features such as insulation to minimize heat loss, energy-saving modes, and efficient heating/cooling systems. Energy-efficient machines can help reduce operational costs and minimize environmental impact.

8. Service and support: Consider the availability of service and support from the manufacturer or supplier. Ensure that they provide reliable customer support, including technical assistance, spare parts availability, and maintenance services.

By considering these factors and aligning them with your specific die casting requirements, you can select a die temperature machine that meets your needs for temperature control accuracy, efficiency, reliability, and support.

Longhua is a one-stop delivery platform for global die casting solutions, we can provide you with the right mold temperature machine selection and integrated die casting solutions, for you to save costs and improve production efficiency. If you need anything, please feel free to contact us at info@longhuamachine.com