In the die casting industry, a copper alloy furnace is a device used to heat copper alloy materials to the

melting temperature. Here are some features of copper alloy stoves:

1. High-temperature heating capability: The copper alloy furnace can provide a high enough temperature

to heat the copper alloy material to above its melting point to facilitate subsequent die-casting processing.

2. Rapid heating speed: Copper alloy furnaces usually have rapid heating capabilities and can heat a large

amount of copper alloy materials to the required temperature in a relatively short period of time,

improving production efficiency.

3. Precise temperature control: The copper alloy furnace is equipped with a precise temperature control

system, which can accurately control the heating temperature to ensure that the copper alloy material

reaches the required melting state and ensures stable product quality.

4. Adjustable heating mode: Copper alloy furnaces usually have a variety of heating modes and heating

methods, which can be adjusted according to different production needs and adapted to copper alloy

materials of different specifications and shapes.

5. Energy saving and environmental protection: The copper alloy furnace adopts efficient energy utilization

technology during the heating process, which can minimize energy consumption and waste gas emissions,

and has certain energy saving and environmental protection advantages.

6. High temperature resistance and durability: Copper alloy stoves are usually made of high temperature

resistant materials, can withstand high temperatures and operate for a long time, and have strong

durability and stability.

7. Safe and reliable: The copper alloy furnace is designed to comply with safety standards and is equipped

with safety protection devices to ensure the safety of operators and equipment while operating stably and

reliably.

8. Easy to operate: Copper alloy furnaces usually have simple and easy-to-operate interfaces and control

systems, so operators can easily master operating skills and improve production efficiency.

This furnace can melt aluminum, magnesium, zinc and other non-ferrous metals

|

MODEL |

SPECIFICATIONS (¢-H)

|

MAXIMEM POWER (KW)

|

MELTING RATE (KG/H)

|

TEMPERATURE |

MELTING FLUX (KG)

|

WEIGHT (T)

|

|

150 |

1240*880 |

42 |

50 |

750 |

150 |

0.9 |

|

200 |

1300*1020 |

51 |

80 |

750 |

200 |

1 |

|

250 |

1330*1020 |

63 |

100 |

750 |

250 |

1.1 |

|

300 |

1330*1090 |

68 |

120 |

750 |

300 |

1.2 |

|

350 |

1440*1090 |

70 |

150 |

750 |

350 |

1.3 |

|

400 |

1490*1140 |

70 |

200 |

750 |

400 |

1.4 |

|

500 |

1560*1225 |

80 |

250 |

750 |

500 |

1.5 |

|

600 |

1660*1325 |

80 |

300 |

750 |

600 |

1.6 |

|

800 |

1760*1425 |

100 |

400 |

750 |

800 |

1.8 |

|

1000 |

1860*1525 |

120 |

500 |

750 |

1000 |

2 |

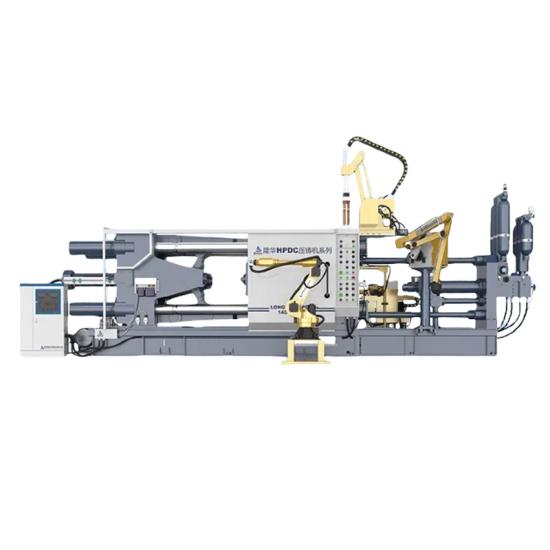

ABOUT US

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.It

specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry for

several decades.The company focuses on research,development,production,and sales of various types of

die casting machines.The company's product range covers cold chamber die-casting machines,die-casting

manipulators,industrial robots and peripheral equipment of die-casting machines to meet the needs of

different customers.