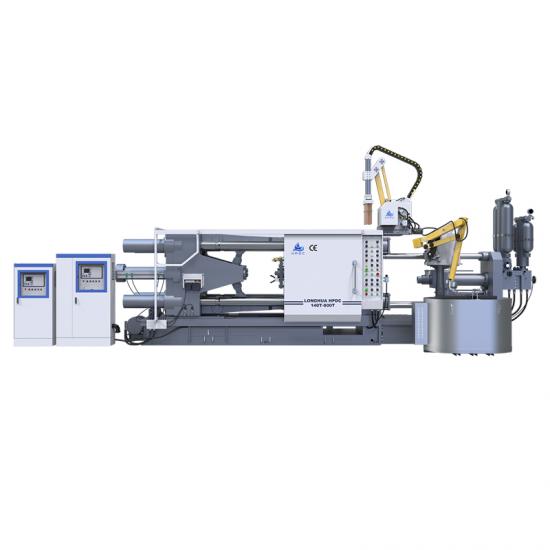

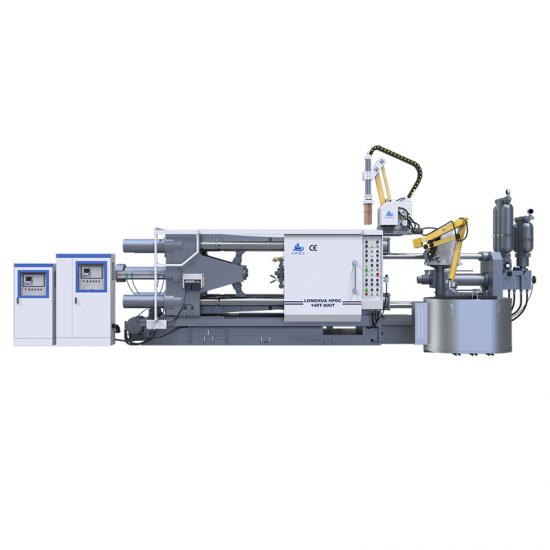

Feature

Features of small aluminum die casting machine:

1. High-efficiency production: Small aluminum die-casting machines have high-efficiency production

capabilities and can quickly and stably produce a large number of small aluminum alloy die-casting parts

to meet production needs.

2. Precision processing: The small aluminum die-casting machine has high-precision processing

capabilities, which can ensure that the size, shape and surface quality of the die-casting parts meet

the design requirements and ensure product quality.

3. Flexibility and adjustability: Small aluminum die-casting machines need to have strong flexibility

and adjustability, and can be adjusted and customized according to the requirements of different

die-casting parts to meet customer needs.

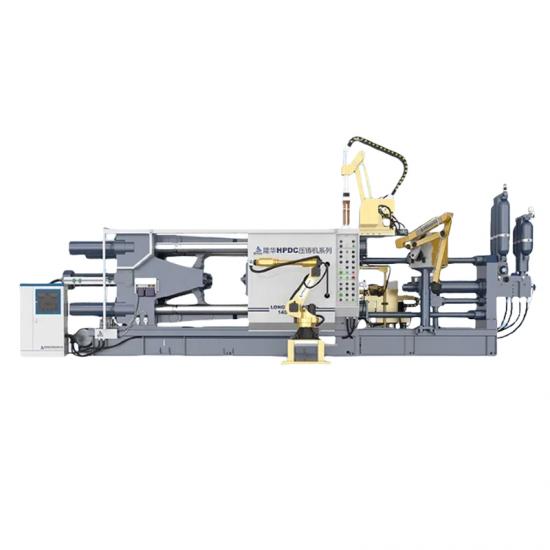

4. Automated control system: The small aluminum die-casting machine is equipped with an advanced

automated control system to achieve fully automatic production, reduce manual intervention, and

improve production efficiency and consistency.

5. Energy saving and environmental protection: Modern small aluminum die-casting machines use

energy-saving technology and environmentally friendly materials to reduce energy consumption and

emissions and meet environmental protection requirements.

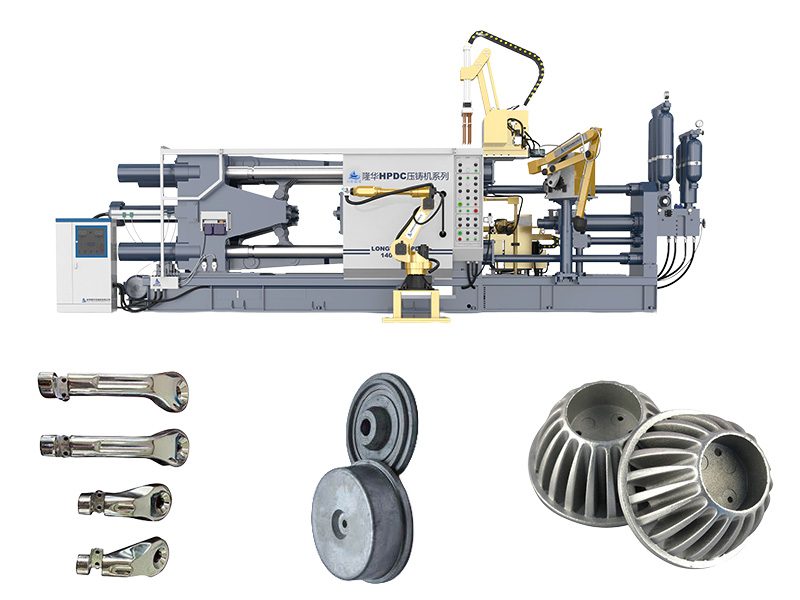

6. Versatility: Small aluminum die-casting machines can be used to process a variety of aluminum

alloy materials to meet the needs of different applications.

7. Cost control: The production of small aluminum die-casting machines needs to consider cost

control, including material costs, production process costs, labor costs, etc., to ensure that product

prices are competitive.

8. Quality control: Small aluminum die-casting machines need to be equipped with a strict quality

control system to ensure that the quality of the aluminum alloy die-casting parts produced is stable

and reliable and meets relevant standards and requirements.

Specification

| LH series of standard parameter table (120U) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 1400 |

| Opening stroke | mm | 350 |

| Die thickness(Min--Max) | mm | 200~500 |

| Space between tie bars | mm | 420*420 |

| Ejector stroke | mm | 80 |

| Ejector force | KN | 100 |

| Injection position(0 as center) | mm | 0,-100 |

| Injection force(intensification) | KN | 180 |

| Injection stroke | mm | 320 |

| Plunger diameter | mm | ¢40 ¢50 ¢60 |

| lnjection weight(aluminum) | Kg | 1.3 |

| Casting pressure (intensification) | MPa | 143/92/64 |

| Max. casting area(40Mpa) | CM2 | 350 |

| Injection plunger penetration | mm | 120 |