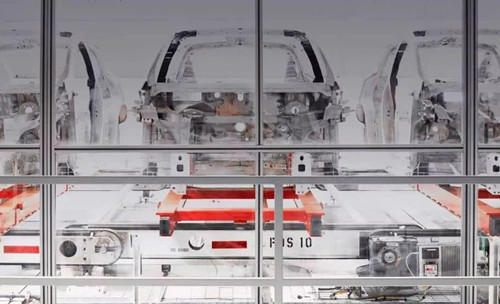

Musk has revealed that Tesla is trying to use Model Aluminum to build the Model Y's body, rather than a mix of stamped steel and aluminum, so that batch automated production can be faster.

In this way, we can build some large casting machines and turn 70 body parts into one, greatly reducing the design and expenditure of the assembly robot.

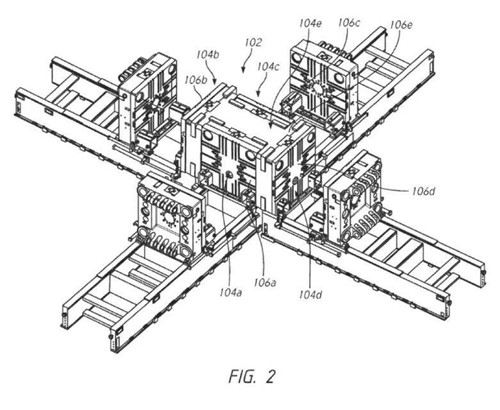

Tesla described the current problems in vehicle die casting: "Generally, during the production and die casting of frames, different die casting machines require different die casting machines. For example, a single die casting machine in a factory It is used to die-cast a single frame component. Then, a factory worker or a robot system will assemble or fix the components casted by each die-casting machine (such as by welding) to form a frame (such as an integrated frame). For other casting and production processes that assemble other individual components (such as due to the high cost of casting equipment and metal molds), the die casting process usually requires high costs, so it is necessary to improve the die casting machine and related die casting methods, especially to reduce the final Assembled into a frame of die-casting work. "Tesla proposed a system that allows several molds to converge in one center. According to the patent application, the system was designed by Matt Kallas, Tesla's "mold manufacturing director," and Matt Kallas left Tesla to become a die-casting mold designer for GF Linamar.

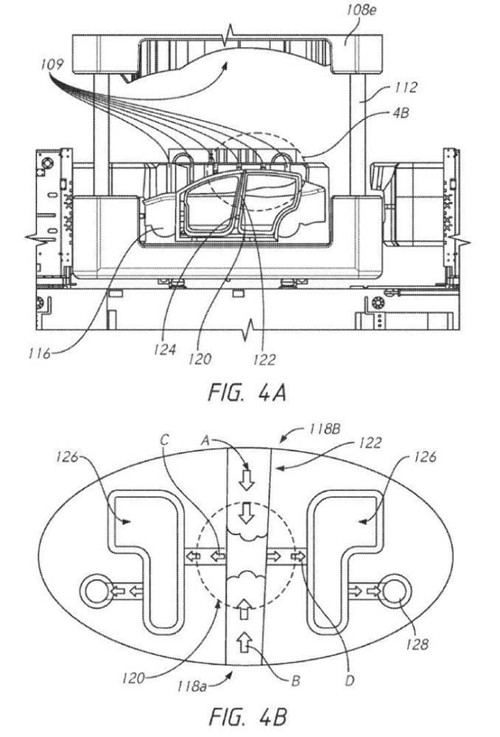

The patent states: "The multi-directional die casting machine configured according to the current frame includes a mold with a car cover and several punches that can be translated relative to the cover mold. These punches are moved to the casting machine respectively. The central casting area is responsible for casting different Parts and do most of the frame casting work on one machine. "Tesla believes this design can" reduce production time, operating costs, production costs, factory floor space, factory operating costs, tool costs, and number of equipment. In addition, Tesla even said that it can reduce the number of casting machines that produce frames and produce "completely or partially completed" frames on its own.

According to reports, the patent was designed by Matt Callas, Tesla's "mold manufacturing director." He held the job at Tesla for a long time, but later left Tesla and switched to General Motors to continue his car foundry work.

It is reported that this patent was designed by Matt Kallas, Tesla's "mold manufacturing director". He had long held this job at Tesla, but later left Tesla and switched to General Motors to continue his work in vehicle foundry. At present, Tesla has high hopes for this new type of casting machine.

Bengbu Longhua , founded in Bengbu, Anhui Province of China ,in 1982, is a professional high-tech enterprise engaged in the design, manufacture and sale of cold chamber die casting machine, die casting peripheral equipment, oil field equipment and new energy equipment (natural gas, nitrogen, wellhead, casing, raw materials, liquefied petroleum gas, special gas, compressor).

Longhua Oilfield new energy equipment project product range can be divided into: CNG filling station series compressors, oil and gas field series compressors, medium and high pressure series compressors, special gas series compressors, chemical process series compressors, power series compressors . Product parameters range: exhaust gas from 0.05-200m3/min, exhaust pressure in 0.1-50MPa, compressible air, nitrogen, liquefied petroleum gas, gas, natural gas, carbon dioxide, propane, hydrogen, helium, ethylene, ammonia, etc. A variety of different media. Widely used in natural gas refueling stations, urban construction, gas fields, petroleum, national defense, coal, geology, chemical, metallurgy, machinery manufacturing, medicine, food, beverages and other fields.