The electrical control of the die-casting machine's automation equipment is the key to achieving efficient and stable production.

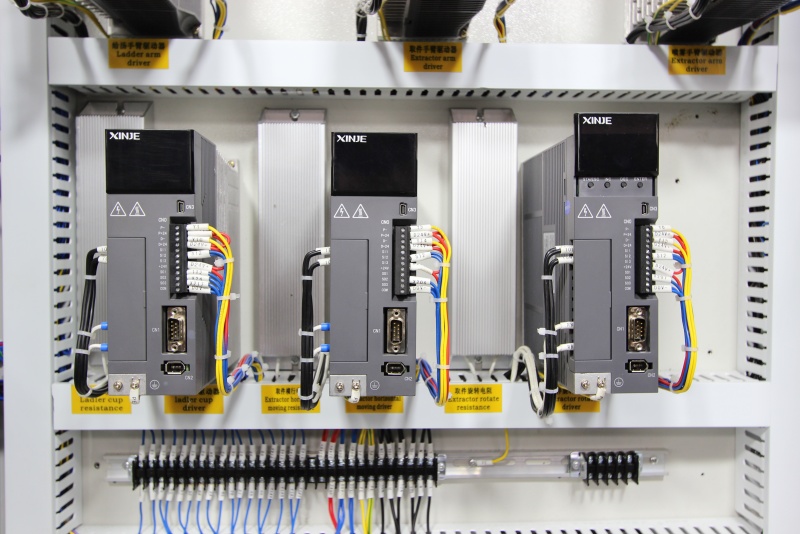

·System composition: The die-casting machine's electrical control system is mainly composed of PLC controller, motor drive, sensor detection and other parts. As the core, the PLC controller is responsible for receiving instructions, processing data and controlling the motor. The motor drive part is responsible for driving the moving parts of the die-casting machine, while the sensor detection monitors various parameters in the die-casting process in real time.

·Key technology: PLC programming technology, motor drive technology and sensor detection technology are the three key technologies of the die-casting machine's electrical control system. These technologies ensure the automation, high precision and stability of the die-casting process.

·Application example: In the automotive manufacturing industry and other fields, the die-casting machine electrical control system is widely used in the production of key components, such as engine cylinders, gearbox housings, etc., to ensure the dimensional accuracy and mechanical properties of the products.

The development of electrical control of die-casting machine automation equipment has greatly improved production efficiency and product quality, and promoted the automation and intelligentization of the manufacturing industry.