Cold chamber die casting machines for die casting radiators have some properties and advantages:

1. High-density castings: The cold chamber die-casting machine can quickly inject aluminum alloy into the mold

at a lower temperature, reducing the thermal deformation and shrinkage of the castings, so it can produce

castings with higher density and strength, improving heating tablet durability and stability.

2. High-quality surface quality: The cold chamber die-casting machine can control the temperature and pressure

of the aluminum alloy, making the surface of the radiator smoother and more uniform, reducing defects such as

pores and bubbles, and improving the appearance quality.

3. Precision machining: The cold chamber die-casting machine can produce radiators with complex shapes and

precise dimensions, which is suitable for various design requirements and improves the processing accuracy

and consistency of radiators.

4. Energy saving and environmental protection: Compared with traditional sand casting or other die-casting

processes, the cold chamber die-casting machine can reduce energy consumption and energy costs during the

production of radiators. It also reduces the waste of aluminum alloy and meets the requirements of energy

saving and environmental protection.

5. Efficient production: The cold chamber die-casting machine has the functions of rapid injection, cooling and

demoulding. It has high production efficiency, can meet the needs of mass production, and improves the

production efficiency of radiators.

6. Design flexibility: The cold chamber die-casting machine can produce radiators of various shapes and sizes.

It is highly flexible and can be customized according to customer needs to meet different market needs.

Specification

| LH series of standard parameter table (2000 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 20000 |

| Opening stroke | mm | 1400 |

| Die thickness(Min--Max) | mm | 650~1600 |

| Space between tie bars | mm | 1350*1350 |

| Ejector stroke | mm | 300 |

| Ejector force | KN | 650 |

| Injection position(0 as center) | mm | -175,-350 |

| Injection force(intensification) | KN | 1510 |

| Injection stroke | mm | 960 |

| Plunger diameter | mm | ¢130-¢170 |

| lnjection weight(aluminum) | Kg | 40 |

| Casting pressure (intensification) | MPa | 113/66 |

| Max. casting area(40Mpa) | CM2 | 5000 |

| Injection plunger penetration | mm | 400 |

| Diameter of pressure chamber flange | mm | 260 |

| Height of pressure chamber flange | mm | 30 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 55*3 |

| Dimensions (L*W*H) | m | 13.5*4.7*4.8 |

| Machine lifting reference weight | T | 120 |

| Oil tank capacity | L | 3600 |

will not be changed without notice)

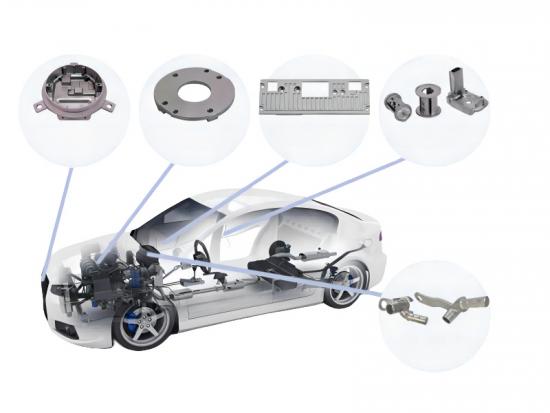

Radiator die castings refer to radiator parts processed and produced by cold chamber die casting

machines. These parts are typically composed of aluminum alloys or aluminum alloys plus other

materials and offer many properties and benefits, including:

1. Excellent thermal conductivity: Because aluminum alloy has good thermal conductivity, radiator

die castings can quickly and effectively transfer heat to the indoor air, improving the thermal efficiency

of the heating system.

2. Lightweight design: Aluminum alloy has a low density, so the radiator die-casting parts are relatively

light and easy to install and carry.

3. High strength and corrosion resistance: The aluminum alloy radiator processed by cold chamber die

casting has high strength and corrosion resistance, and can maintain stable performance in long-term use.

4. Precise sizes and complex shapes: Cold chamber die casting machines are capable of producing parts

with precise sizes and complex shapes, so radiator die castings can be accurately processed according to

design requirements, achieving higher product performance and aesthetics.

5. High production efficiency: The cold chamber die-casting machine has efficient production capacity and

can quickly and continuously produce large quantities of radiator die-casting parts to meet market demand.

6. Energy saving and environmental protection: Compared with traditional manufacturing processes, cold

chamber die-casting technology can reduce material waste and energy consumption, which is beneficial

to energy saving, emission reduction and environmental protection.

To sum up, radiator die-casting has the advantages of excellent thermal conductivity, lightweight design,

high strength and corrosion resistance, precise size and complex shape, high production efficiency,

energy saving and environmental protection, so it is widely used in the manufacturing and installation of

heating systems. widely used in.

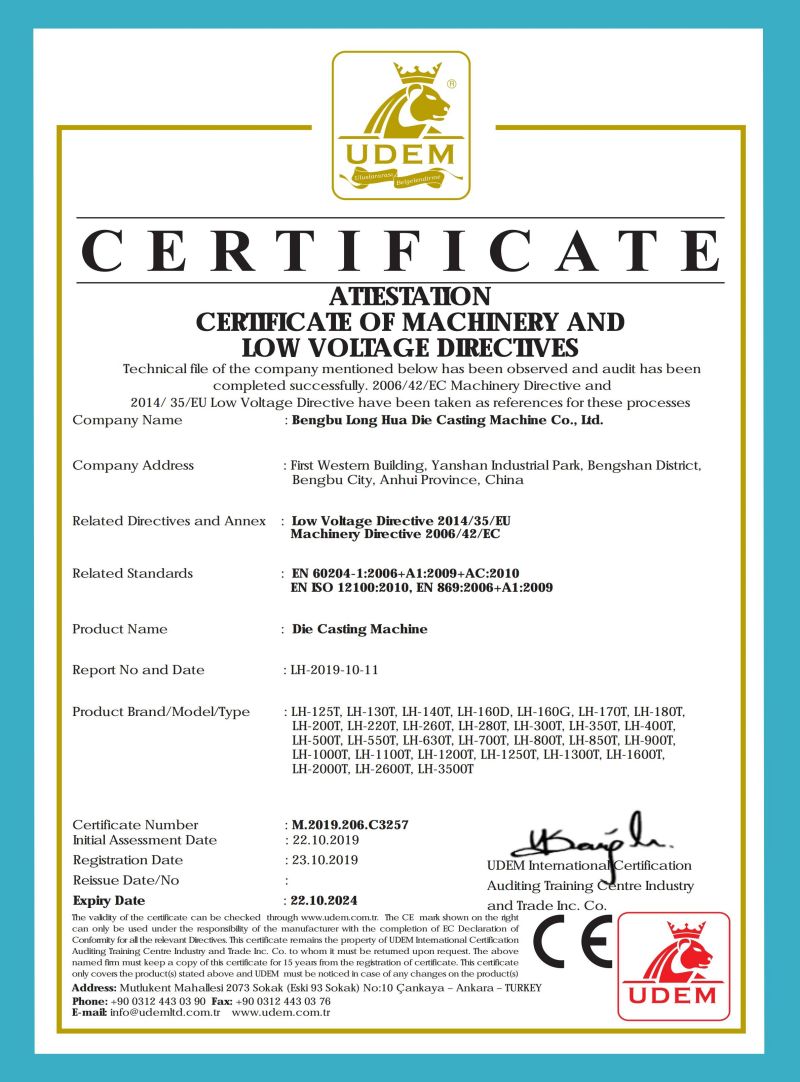

ABOUT US

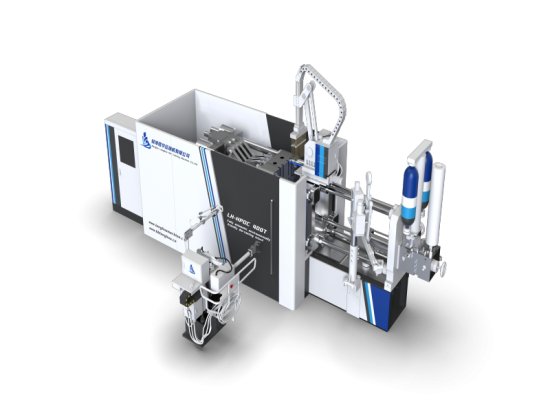

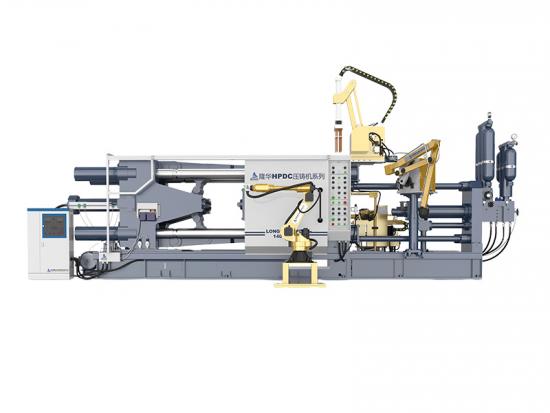

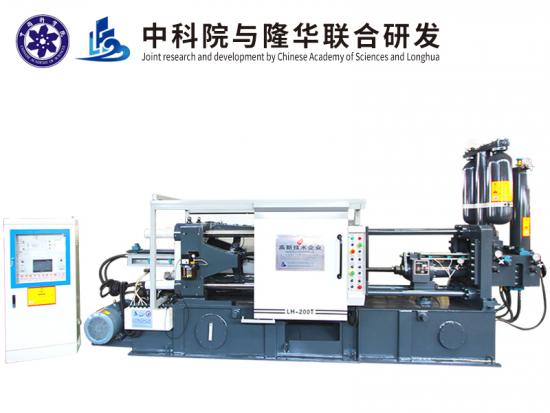

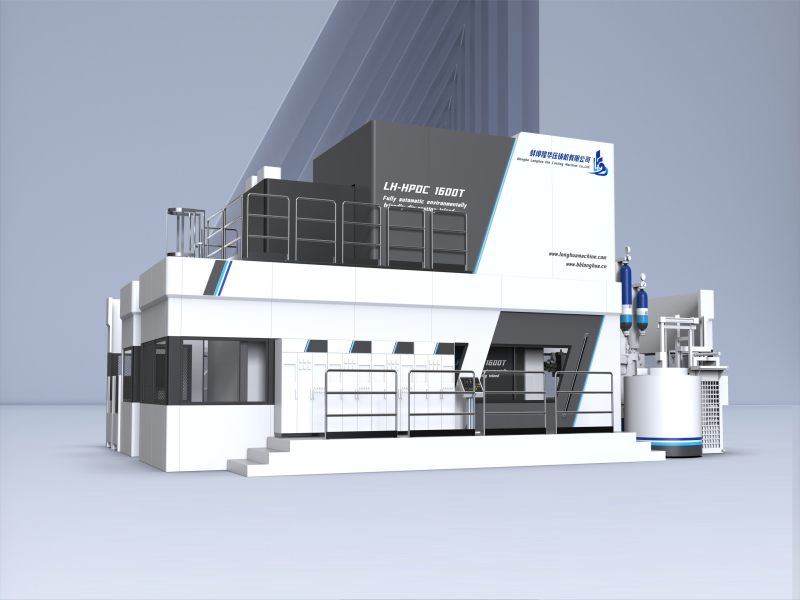

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,

China.It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting

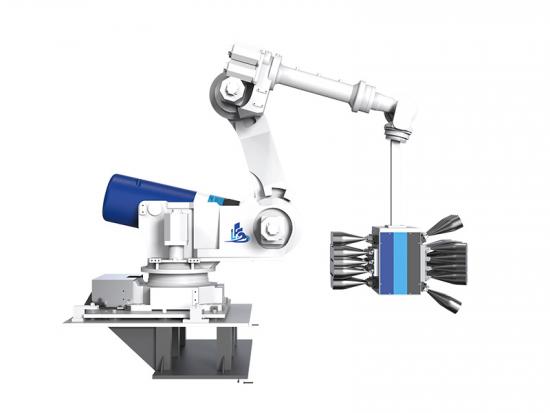

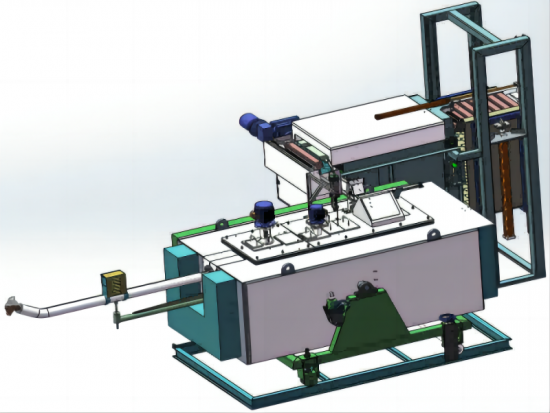

industry for several decades.The company focuses on research,development,production,and

sales of various types of die casting machines.The company's product range covers cold chamber

die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of

die-casting machines to meet the needs of different customers.