About high pressure die casting process

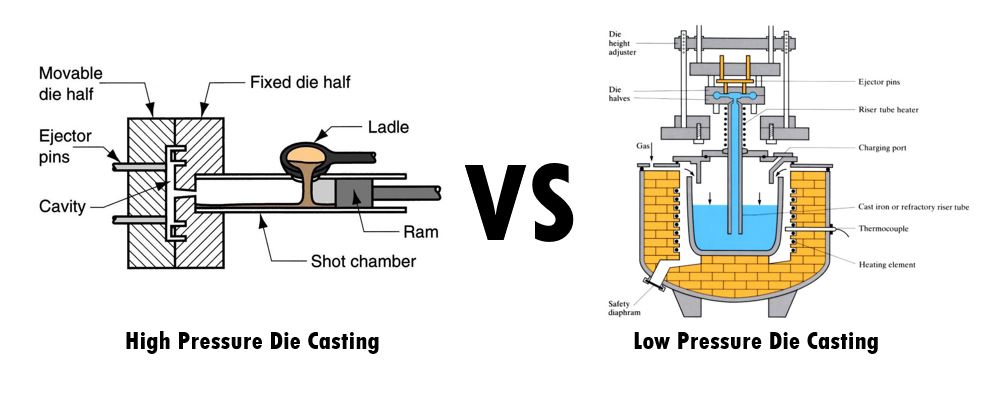

High pressure die casting can produce castings quickly and economically. These castings can be composed of various holes, threads and notches, which are characterized by high dimensional accuracy and good surface finish. They make the metal economical and require little or no surface treatment. The principle of pressure die-casting is to press molten metal into a mold or die under considerable pressure. Machines used for this purpose operate on one or both systems:

Hot chamber die casting machine (for metals with low melting point)

Cold chamber die casting machine (for metal with high melting point)

In a hot-chamber die-casting machine, the metal is kept liquid in a crucible inside the machine, and the pressure chamber that feeds the metal into the mold is located in the metal groove. Such machines can be operated pneumatically, or more usually by the action of a stamping piece to develop pressure. The cast metal of the cold chamber machine is kept liquid in the holding furnace, transferred from the holding furnace to the pressure chamber by a spoon or a special automatic device, and pressed into the mold by a stamping piece. Some simple machines are operated by hand, but in order to increase productivity, fully automatic machines are more commonly used.

In pressure die casting, the complex multi-part design of precision manufactured dies, and therefore very expensive, is exposed to harsh working conditions with continuous changes in high pressure and temperature. For the production of zinc and zinc-alloy castings, molds can be made of unalloyed steel, but for magnesium, aluminum, copper, and alloys of these metals, molds are generally made of hot-worked steel, which is much more durable.

Another development of high-pressure die casting is vacuum die casting. It produces castings with a better finish than ordinary high pressure castings. There are two systems in which the mold is either enclosed in a hood that draws out the air, or an insulated furnace is installed beneath the casting machine so that metal is drawn into the mold and compacting inside it while the air is drawn out. A process for making cast iron castings has been developed based on this principle.