First, what is die casting?

Die casting is a process of using pressure to inject molten metal into a mold and then obtaining a cast product with a precise shape or geometry as the internal shape of the mold. In this article, we will talk about the equipment of this process, what is a die casting machine, the common type of die casting machine, and their mechanism and choice.

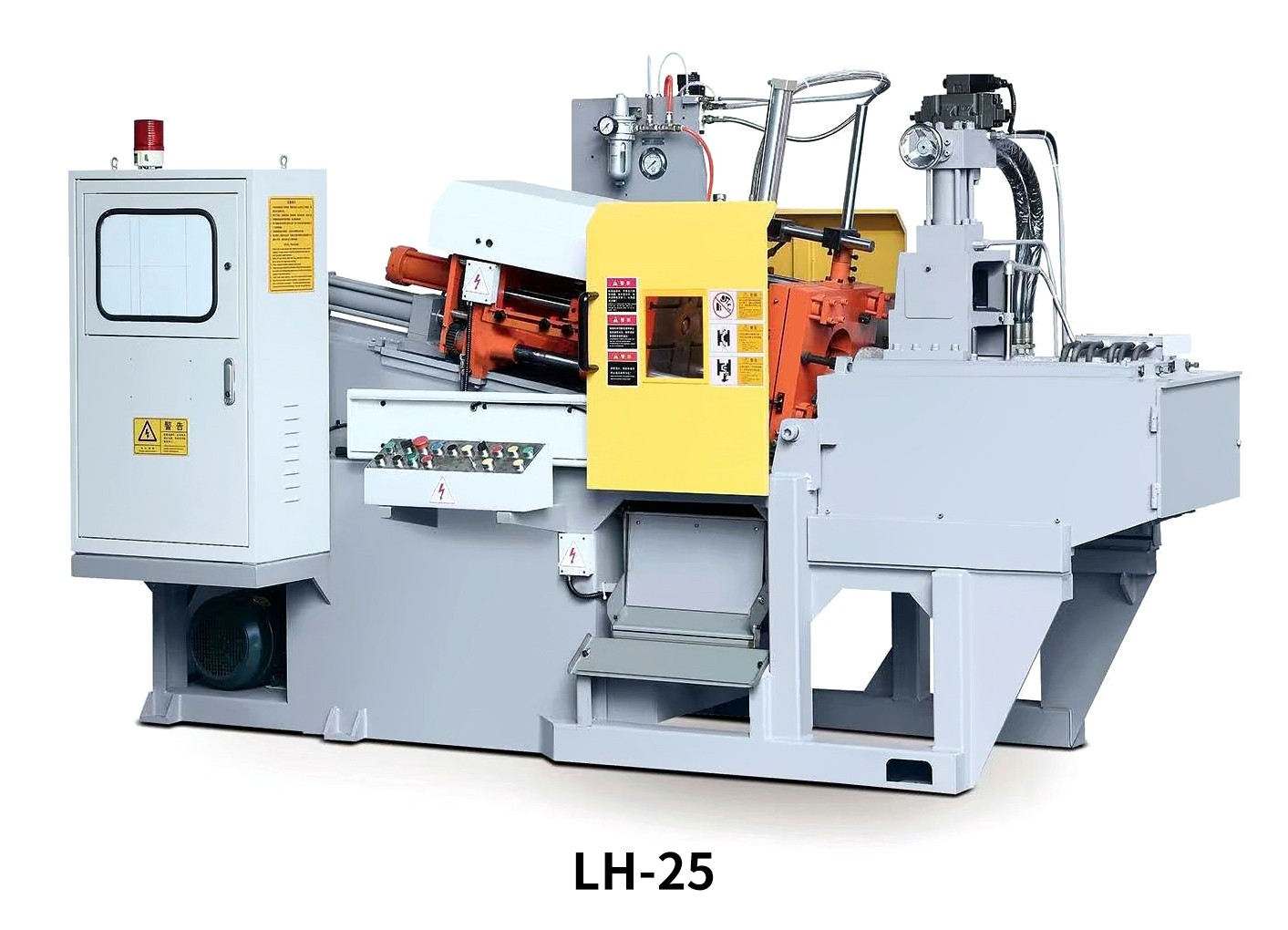

Two, what is the die casting machine?

Die casting machine is used for metal casting process, through the die casting machine to inject molten metal into the mold cavity, when the metal cools and solidifies, it will form the shape of a die casting, which is a manufacturing method to obtain metal castings such as aluminum or zinc die casting.

Three, die casting machine type:

Die casting machines can be divided into different categories according to different classification methods such as use and size. Generally speaking, die casting machines can be divided into two kinds: hot chamber and cold chamber.

1.1. Hot chamber die casting machine

The hot chamber machine has a pressure chamber connected to the mold cavity to which molten metal can flow continuously. When the cylinder of the chamber returns to its unpressured position, the molten metal is fed into the casting mold. A crucible for melting metal is attached to the machine, and a piston mechanism for hydraulic injection of metal into the mold is installed in the crucible. Some hot chamber die-casting machines use compressed air to press metal directly into the mold, without the need for a piston mechanism. The injection mechanism is immersed in molten metal, so it is necessary to avoid chemical corrosion or corrosion of the immersion injection system. Hot chamber die casting machine is mainly used for casting zinc, tin and other low melting point alloys.

1.2. Advantages of hot chamber die casting machine

-- High productivity

- Improve surface finish

- Capable of producing complex castings

- Tight dimensional tolerances

- Suitable for zinc die casting

2.1 Cold chamber die casting machine

In the cold chamber machine, metal melted from a separate holding furnace is scooped into the cold chamber sleeve after the mold is closed. The metal is then pressed into the mold, which is opened to solidify, and the cast will be injected. The metal is melted outside the machine and added to the compression chamber. It can be divided into vertical cold chamber die casting machine and horizontal cold chamber die casting machine according to the motion direction of compression piston. The molten metal is removed from the furnace of the vertical cold chamber die casting machine and injected into the compression chamber. The metal is injected into the mold by a compression piston, and the remaining metal is pushed out by another piston. The horizontal cold chamber die casting machine works in the same way as the vertical die casting machine, except that the direction of piston movement is horizontal. Most modern die casting machines are horizontal. Cold chamber die casting machines can die cast metals with high melting point, such as copper alloys.

2.2. Advantages of cold chamber die casting machine

Reduce the chance of corrosion

- Suitable for casting aluminum, copper and their alloys

- Can be used to manufacture large parts

Which type of die casting machine should you choose? You can choose the machine according to the metal you want to use. For example, if you are getting zinc, tin, and lead castings, you should choose a hot chamber die casting machine because it is prone to corrosion and is better suited to alloys with low melting temperatures and suitable mobility. In addition, the high temperature used in casting aluminum and copper alloys will shorten the life of the hot chamber machine. In contrast, cold chamber casters are more suitable for casting metals with high melting points, such as aluminum or alloys with high aluminum content.