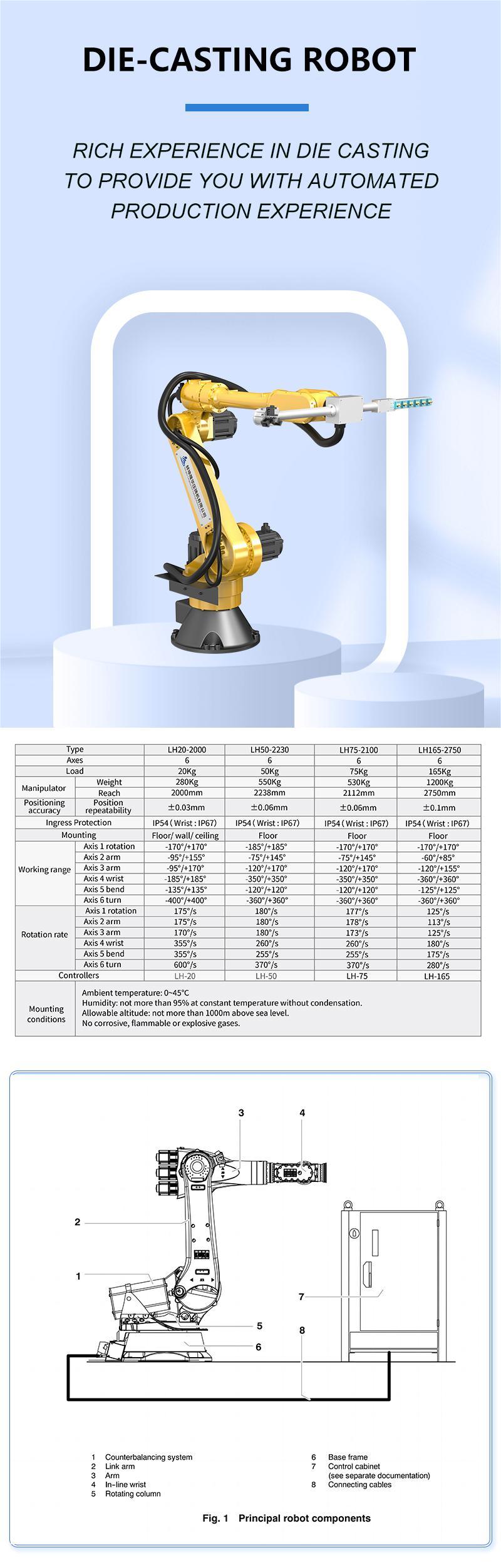

Type

LH-50KG

Axes

6

Load

50Kg

Weight

550Kg

Reach

2238mm

Position repeatability

±0.06mm

Ingress Protection

IP54(Wrist:IP67)

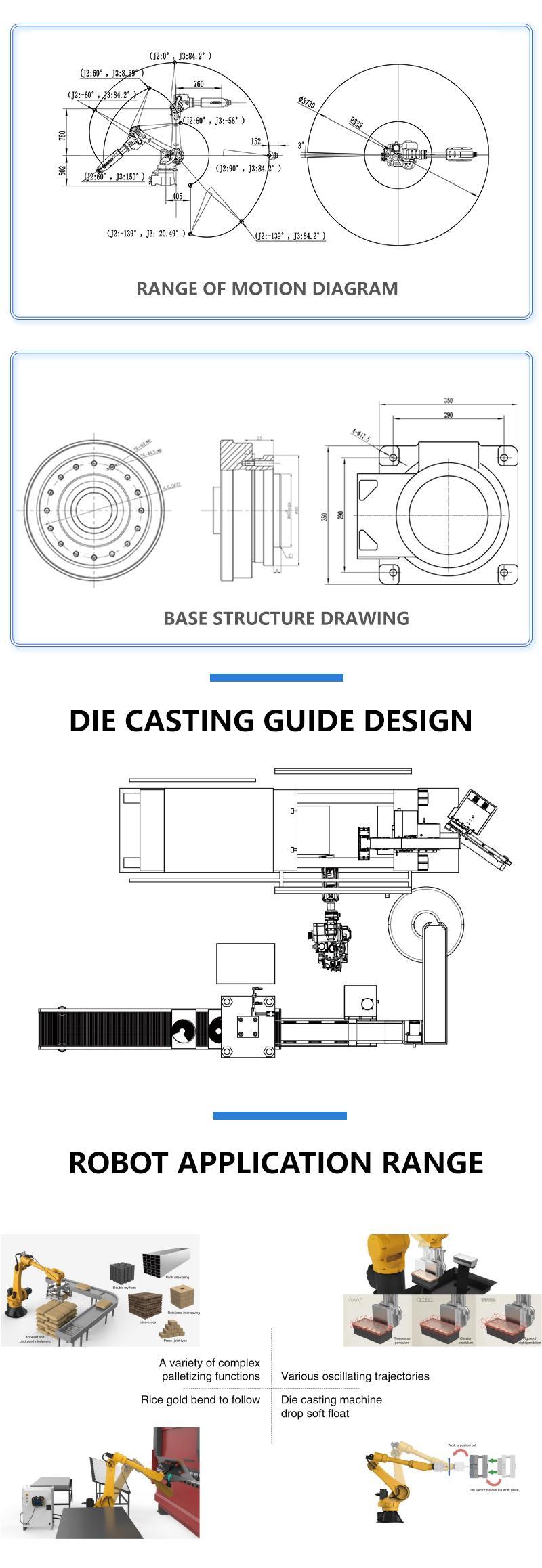

1. Loading and unloading: Automatically feed raw materials (such as aluminum alloy) into the die-casting machine, and remove the finished product from the mold after die-casting is completed, improve production efficiency, and reduce the labor intensity of manual operation.

2. Mold spraying: During the die-casting process, automatically spray lubricants or mold release agents on the mold to ensure uniform spraying, extend the life of the mold, and improve product quality.

3. Product transfer and stacking: Transfer the die-cast products to the designated location for cooling, inspection or further processing, and neatly stack them on pallets or conveyor belts for subsequent processing.

4. Deburring and trimming: Use special tools for deburring and trimming to ensure that the product surface is smooth and flat, reducing the need for subsequent processing.

5. Quality inspection: Equipped with a visual inspection system, it can perform rapid appearance and size inspection after the product is taken out, identify defects and unqualified products, and improve the efficiency of product quality control.

6. Mold replacement: Automatically replace molds to improve the flexibility and switching efficiency of the production line, and meet the needs of multi-variety and small batch production.

7. Data collection and monitoring: Real-time monitoring of various parameters in the production process (such as temperature, pressure, time, etc.) to help operators optimize process parameters and improve production stability and product consistency.

ABOUT US

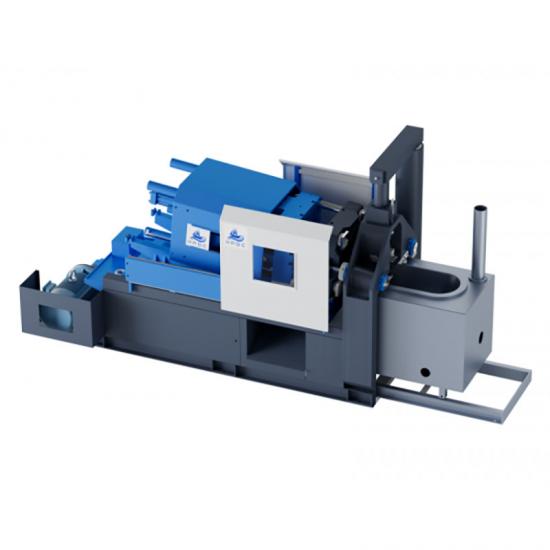

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry for several decades.The company focuses on research,development,production,and sales of various types of die casting machines.The company's product range covers cold chamber die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of die-casting machines to meet the needs of different customers.