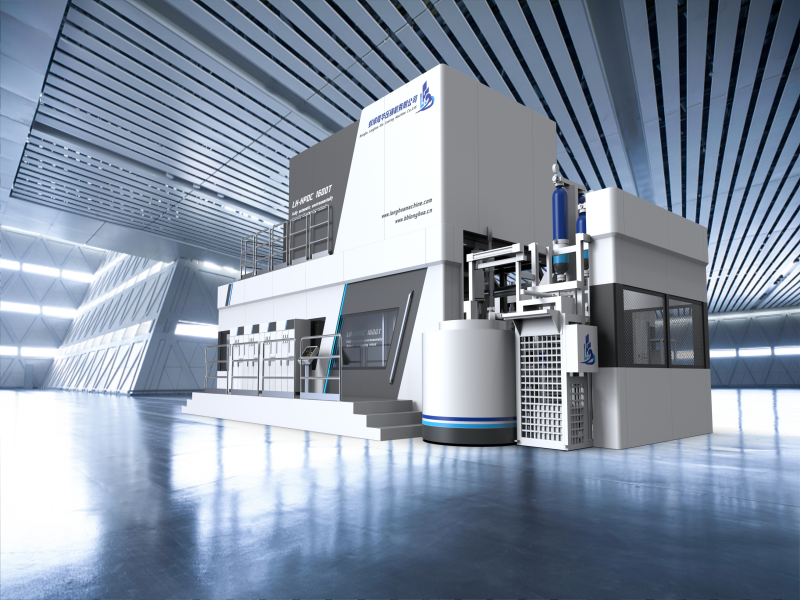

The large-scale high-pressure horizontal cold chamber aluminum alloy die-casting machine has many excellent

properties, making it an important equipment for aluminum alloy die-casting processing.

Here are some of the main performance features of this type of die casting machine:

1. High-pressure injection capability: This type of die-casting machine usually has high-pressure injection

capability, which can provide enough pressure to quickly inject aluminum alloy materials into the mold to ensure

that the castings are filled evenly, thereby producing high-quality aluminum alloy castings.

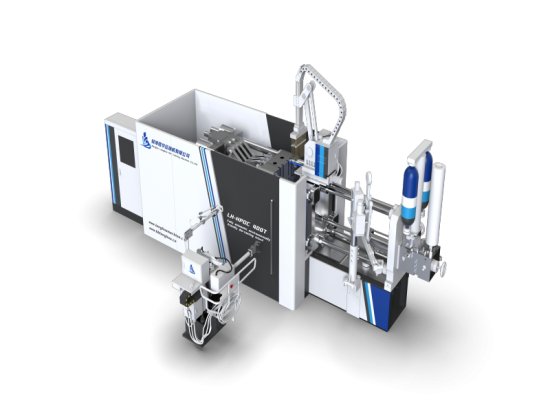

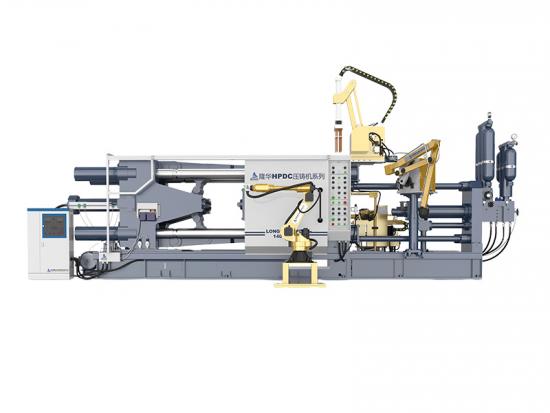

2. Horizontal structural design: The horizontal structural design makes operation more convenient. Operators can

enter the work area from the side or above to perform mold replacement, cleaning and maintenance, etc., which

improves the convenience and safety of operation.

3. Advanced cooling system: This type of die-casting machine is usually equipped with an advanced cooling

system, which can effectively control the cooling rate of the casting to ensure a uniform grain structure inside

the casting and improve the mechanical properties of the casting.

4. Precise control system: Large-scale high-pressure horizontal cold chamber aluminum alloy die-casting machines

usually adopt advanced control systems, which can achieve precise control of injection speed, pressure,

temperature and other parameters to meet the processing requirements of different castings.

5. High efficiency and high stability: This type of die-casting machine has high production efficiency and high

stability, which can meet the needs of large-scale production, improve production efficiency and ensure stable

product quality.

6. Reliable safety system: In order to ensure the safety of operators and equipment, large-scale high-pressure

horizontal cold chamber aluminum alloy die-casting machines are usually equipped with reliable safety systems,

including emergency stop devices, safety shields, safety light curtains, etc., to ensure that during operation Stop

the machine in time in case of emergency and prevent accidental injuries.

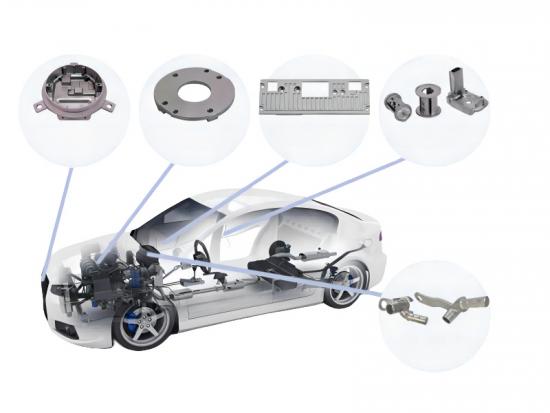

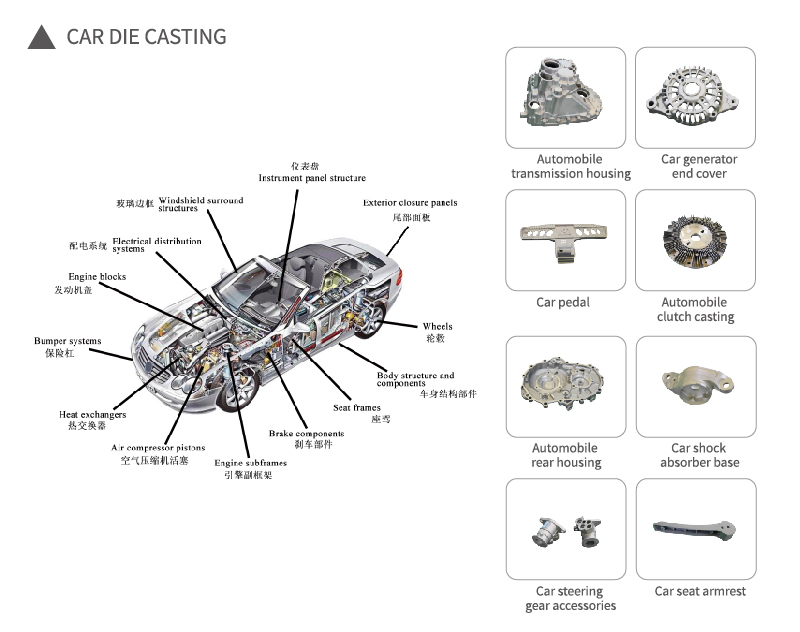

7. Wide range of applications: This type of die-casting machine is suitable for processing aluminum alloy castings

of various shapes and sizes, and can be widely used in parts manufacturing in automobiles, aerospace,

electronic products and other fields.

Specification

| LH series of standard parameter table (2500 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 25000 |

| Opening stroke | mm | 1500 |

| Die thickness(Min--Max) | mm | 800~1800 |

| Space between tie bars | mm | 1500*1500 |

| Ejector stroke | mm | 300 |

| Ejector force | KN | 750 |

| Injection position(0 as center) | mm | -200,-400 |

| Injection force(intensification) | KN | 1800 |

| Injection stroke | mm | 1050 |

| Plunger diameter | mm | ¢140----¢180 |

| lnjection weight(aluminum) | Kg | 50 |

| Casting pressure (intensification) | MPa | 110/66 |

| Max. casting area(40Mpa) | CM2 | 6250 |

| Injection plunger penetration | mm | 450 |

| Diameter of pressure chamber flange | mm | 280 |

| Height of pressure chamber flange | mm | 30 |

| Max.working pressure | MPa | 16 |

| Motor power | Kw | 75*2 |

| Dimensions (L*W*H) | m | 14.7*5*5 |

| Machine lifting reference weight | T | 160 |

| Oil tank capacity | L | 4700 |

will not be changed without notice)

Aluminum alloy die casting machine safety operating procedures

1. Before starting the aluminum alloy die-casting machine, you first need to place the pressure reducing valve

handle in the pressure relief position of the pressure reducing valve until the motor runs normally, and then

loosen the pressure reducing valve handle.

2. The aluminum alloy die-casting machine must heat the model to the specified temperature before injection,

and then press it into the metal solution.

3. A protective baffle should be installed at the contact point between the mold parting surface and the gate.

Operators must wear protective glasses. Operators must not stand on the opposite side of the parting surface

contact. Prevent metal liquid splash damage.

4. Never bring open flames near the fuel tank. When the tank temperature exceeds the specified operating

temperature of the equipment, water cooling should be used.

5. Tools should be used when removing castings and casting risers from die casting molds. After the casting

is dismantled, the metal slag stuck on the mold and pores should be removed in time.

6. After the work is completed, the oil pump must be stopped and all valves closed. If the holding furnace

is used to keep metal liquid warm, the power supply should be turned off and the ventilation equipment

on the holding furnace should be stopped.

ABOUT US

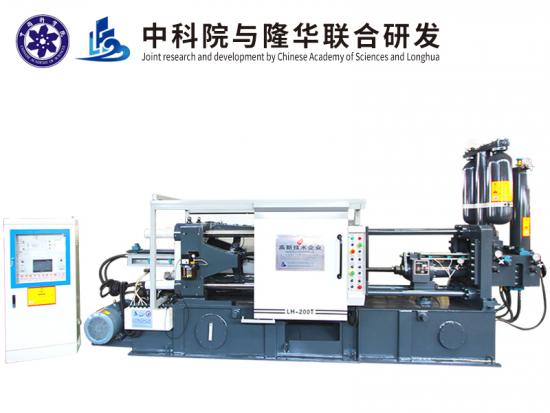

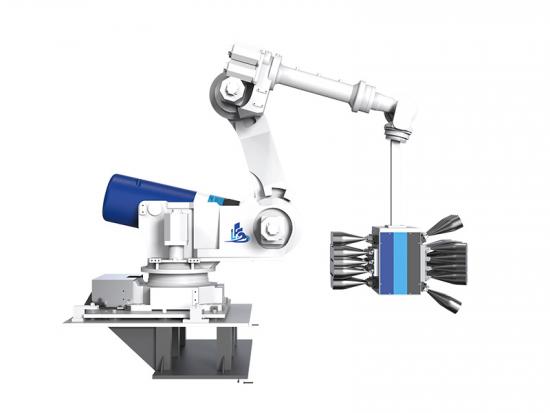

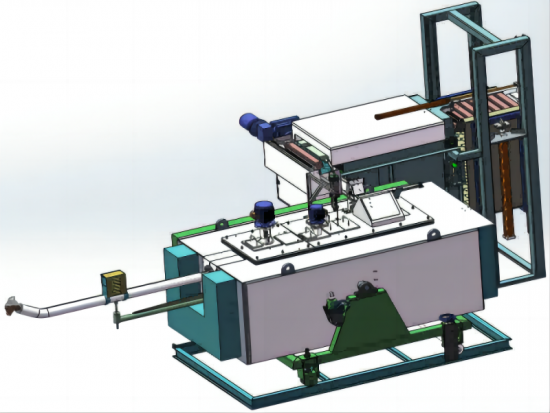

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,

China.It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting

industry for several decades.The company focuses on research,development,production,and

sales of various types of die casting machines.The company's product range covers cold chamber

die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of

die-casting machines to meet the needs of different customers.