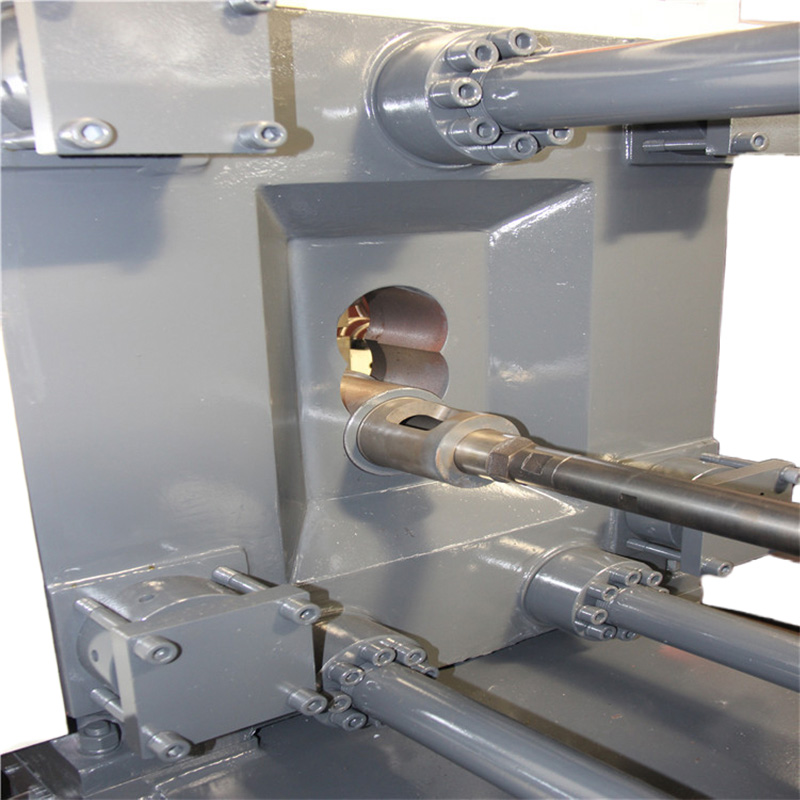

The injection Head is an important component in the die casting machine. Its main function is to quickly inject the molten metal liquid into the mold cavity at high pressure during the die casting process. Specifically, the functions of the shot head include the following aspects:

1.High-pressure injection: The shot head generates high pressure through a hydraulic system or a mechanical system to quickly inject the molten metal into the mold cavity. This process requires very high pressure to ensure that the molten metal can fully fill the various details of the mold.

2.Maintaining pressure: After the molten metal is injected into the mold cavity, the shot head also needs to maintain a certain pressure to ensure that the molten metal will not produce defects such as pores and shrinkage during the solidification process.

3.Control speed: The movement speed of the shot head needs to be precisely controlled to ensure that the molten metal is injected into the mold at the appropriate time and speed. This is crucial to avoid problems such as oxidation of the molten metal and cooling too fast or too slow.

4.Quality consistency: By precisely controlling the parameters of the shot process, the shot head helps to ensure the quality consistency of each casting and reduce the defective rate.

ABOUT US

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.It specializes in the manufacturing of die casting machines and related equipment.Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry for several decades.The company focuses on research,development,production,and sales of various types of die casting machines.The company's product range covers cold chamber die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of die-casting machines to meet the needs of different customers.