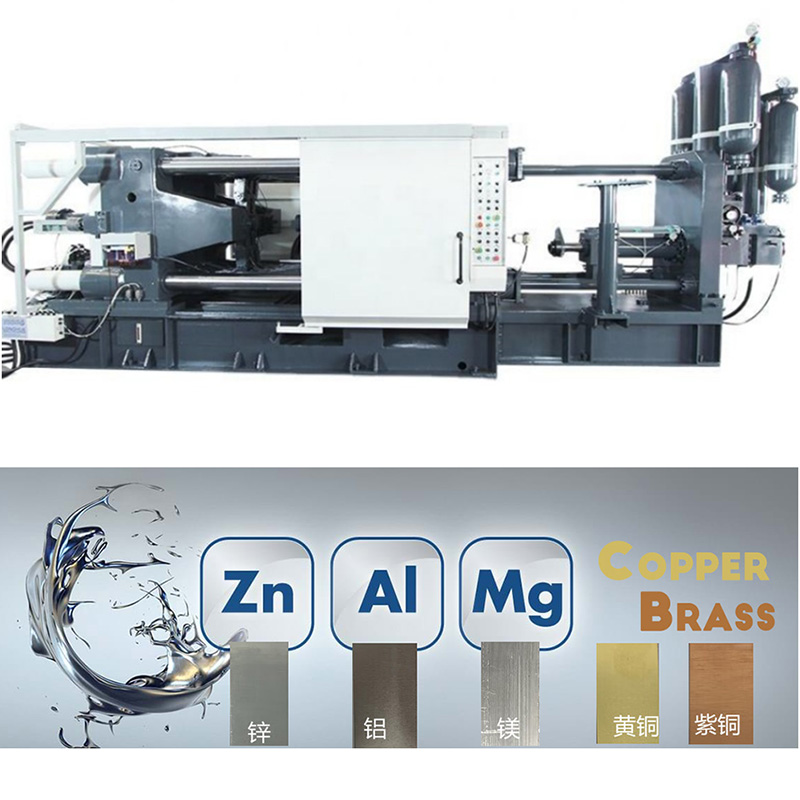

A "non-ferrous die casting machine" is a machine used to cast metal parts from non-ferrous metals, meaning metals that do not contain iron, such as aluminum, zinc, magnesium, copper, or brass, by injecting molten metal under high pressure into a closed mold (die) to create the desired shape; essentially, it's a die casting machine specifically designed to work with non-ferrous alloys.

Key points about non-ferrous die casting machines:

Metal types:

Commonly used non-ferrous metals for die casting include aluminum, zinc, and magnesium, each with different properties and applications depending on the desired strength, weight, and corrosion resistance.

Machine types:

Die casting machines can be categorized as "hot chamber" or "cold chamber" depending on how the molten metal is delivered to the mold. Hot chamber machines are often used for low-melting point metals like zinc, while cold chamber machines offer more flexibility for a wider range of alloys.

Advantages of non-ferrous die casting:

High precision: Can produce complex shapes with tight tolerances.

Lightweight parts: Ideal for applications where weight reduction is crucial.

Good surface finish: Often requires minimal post-processing.

Choose our reliable non-ferrous metal die casting machines and take your production capabilities to new heights. Contact us today to learn more about our innovative solutions and how they can benefit your business.