Die casting is a widely used process in the manufacturing industry for producing accurate, high-quality metal parts. Two popular types of die casting machines are the horizontal and vertical die casting machines. While they serve the same purpose of injecting molten metal into a mold cavity, there are distinct differences between the two.

Horizontal Die Casting Machine:

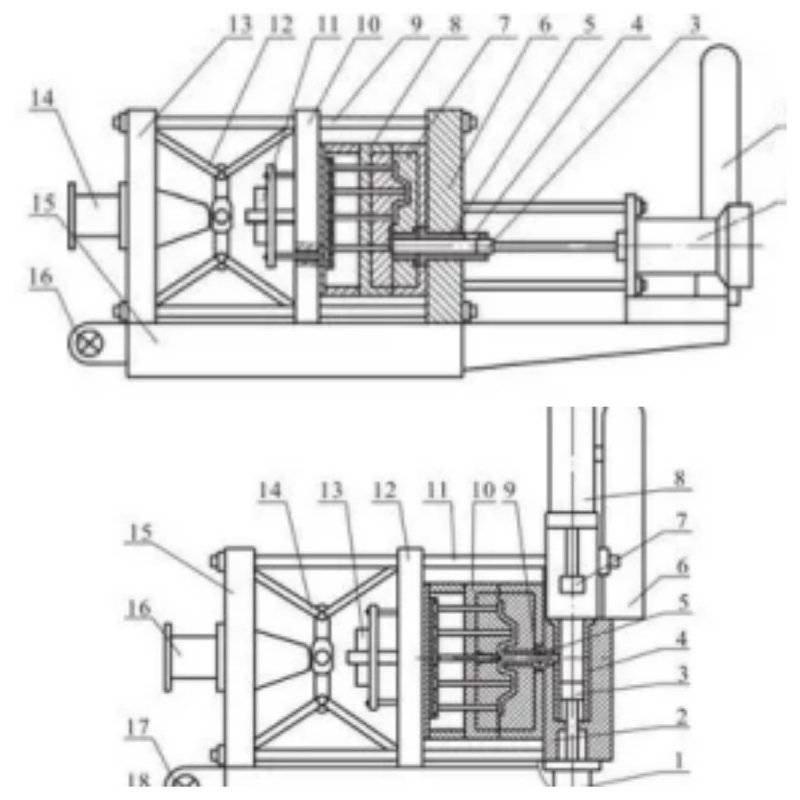

A horizontal die casting machine, as the name suggests, operates in a horizontal orientation. This machine is designed to inject molten metal, such as aluminum, into the mold cavity using a horizontal shot chamber and a hydraulic system. The mold is securely fixed in a horizontal position, and the molten metal is injected horizontally into the mold cavity.

Advantages of Horizontal Die Casting Machines:

1. Efficient Cooling: Horizontal die casting machines provide better natural air cooling due to their horizontal orientation, resulting in faster solidification of the molten metal.

2. Better Casting Complexities: These machines are ideal for producing complex and large-sized parts since they allow for multi-directional flow of the molten metal, ensuring even distribution within the mold cavity.

3. Easier Mold Changes: Horizontal die casting machines typically offer a simpler and quicker mold change process, making it more convenient and efficient for production.

Vertical Die Casting Machine:

In contrast, a vertical die casting machine operates in a vertical orientation. The molten metal is injected from the bottom of the machine into the mold cavity that is positioned vertically. The mold is securely held in the vertical position during the casting process.

Advantages of Vertical Die Casting Machines:

1. Reduced Metal Oxidation: The vertical orientation of these machines minimizes the exposure of molten metal to the atmosphere, resulting in reduced metal oxidation and improved casting quality.

2. Smaller Footprint: Vertical die casting machines generally have a smaller footprint compared to their horizontal counterparts, making them suitable for space-restricted production facilities.

3. Enhanced Gravity Filling: Gravity plays a crucial role in the vertical die casting process, allowing for better control and consistency in the flow of molten metal into the mold cavity.

In summary, the main difference between horizontal and vertical die casting machines lies in their orientation and the way molten metal is injected into the mold cavity. The choice between the two depends on the specific requirements of the production process, including the size and complexity of the parts, cooling requirements, and available space. Both types of machines have their advantages and are widely used in the die casting industry to meet manufacturing needs.