Aluminum alloy and zinc alloy die casting machines have many similarities in design and application, but there are also some important differences. The following are the main features of both:

Features of aluminum alloy die casting machines

1. High melting point: Aluminum alloy has a high melting point, generally around 660℃, so aluminum alloy die casting machines need to be able to withstand higher temperatures and stricter temperature control.

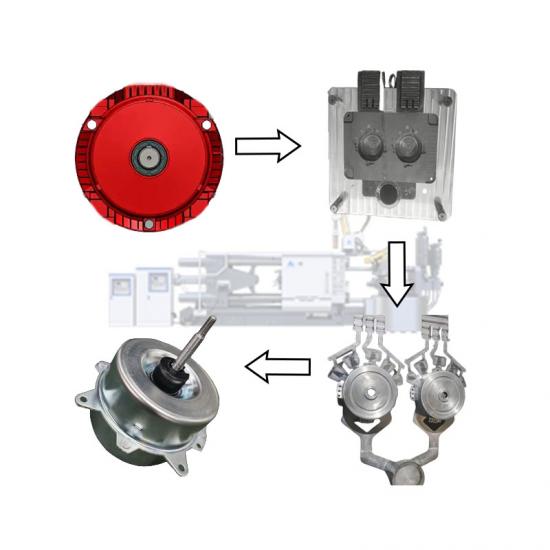

2. High strength and light weight: Aluminum alloy has high strength and low density, making it an ideal material for parts that require lightweight and high strength, and is widely used in aviation, automotive and other industries.

3. Lower fluidity: Compared with zinc alloy, aluminum alloy has poor fluidity, so mold design and injection pressure control are more important to ensure that the casting can fully fill the mold.

4. Longer cooling time: The solidification time of aluminum alloy is relatively long, which requires the die casting machine to have sufficient cooling capacity and cycle time control to ensure production efficiency and casting quality.

5. Surface treatment: Aluminum alloy castings usually require subsequent surface treatment, such as anodizing, electroplating or painting, to improve corrosion resistance and aesthetics.

6. High cost: The high cost of aluminum alloy materials, coupled with high energy consumption, makes the operating cost of aluminum alloy die-casting machines relatively high.

Characteristics of zinc alloy die-casting machines

1. Low melting point: The melting point of zinc alloy is low, generally around 380℃, which makes the temperature control of zinc alloy die-casting machines relatively simple and the energy consumption is low.

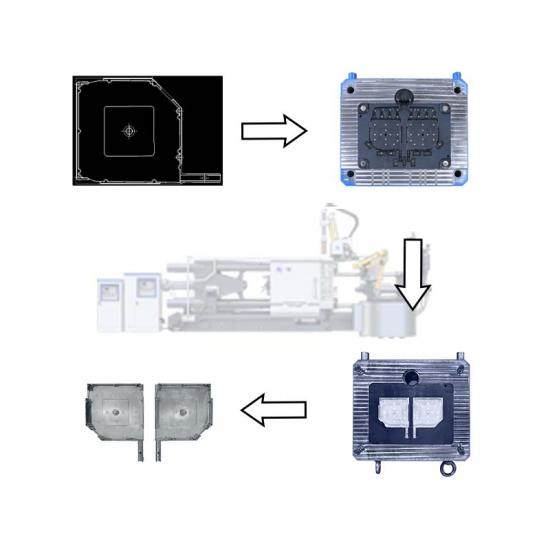

2. High fluidity: Zinc alloy has good fluidity and can easily fill complex mold shapes to produce castings with high precision and high surface quality.

3. Short cooling time: Zinc alloy solidifies quickly, which helps to improve production efficiency and shorten the die-casting cycle.

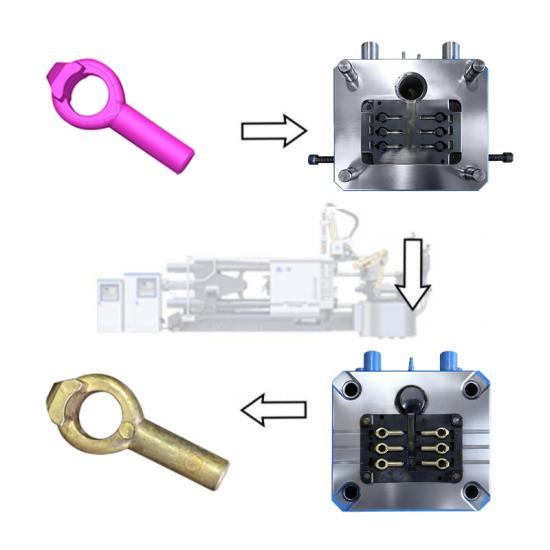

4. Excellent mechanical properties: Zinc alloy has good strength, hardness and wear resistance, and is suitable for manufacturing precision mechanical parts and high-demand decorative parts.

5. Low cost: Zinc alloy material cost is low, processing energy consumption is low, and production efficiency is high, making the overall production cost low.

6. Environmental protection: Zinc alloy is non-toxic and recyclable, which meets modern environmental protection requirements.

7. Wide range of applications: Zinc alloy die-casting machines are widely used in electronics, electrical appliances, automobiles, home furnishings and other industries to produce various complex and high-precision parts.

Common features

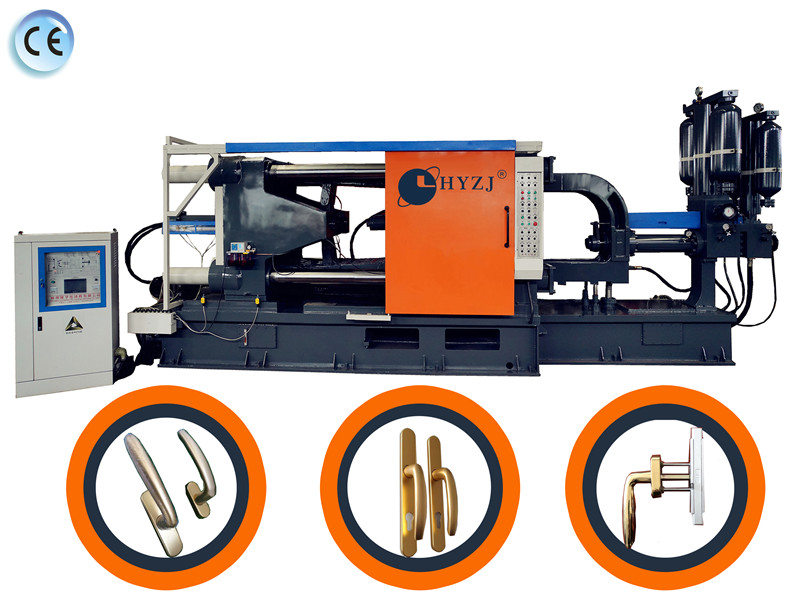

1. High automation and intelligence: Modern die-casting machines are usually equipped with high-level automation and intelligent systems to improve production efficiency and product quality, and reduce labor costs and human errors.

2. Mold temperature control: Both die-casting machines require accurate mold temperature control systems to ensure casting quality and mold life.

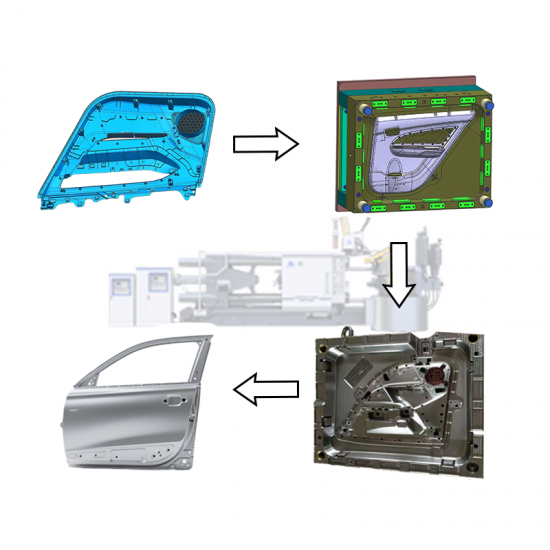

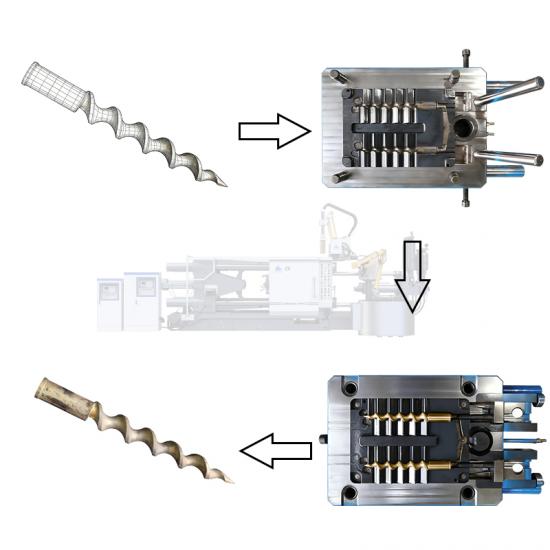

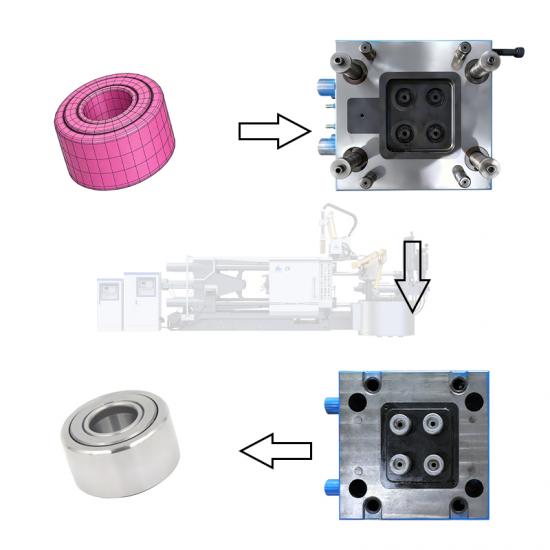

3. Multi-cavity mold design: In order to improve production efficiency, both aluminum alloy and zinc alloy die-casting machines can use multi-cavity mold design to die-cast multiple parts at a time.

4. Efficient cooling system: Die-casting machines require efficient cooling systems to ensure rapid cooling and solidification of castings and improve production efficiency.

5. High material utilization: The die-casting process has high material utilization, less waste, and waste can be recycled and reused to reduce waste.

ABOUT US

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,China.It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting industry for several decades.The company focuses on research,development,production,and sales of various types of die casting machines.The company's product range covers cold chamber die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of die-casting machines to meet the needs of different customers.