Feature

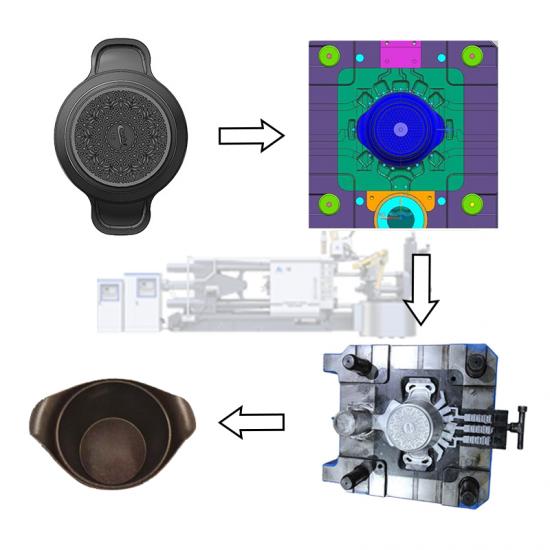

Molds for die-cast pots and kitchenware have some specific features to adapt to the die-casting production process and meet the requirements of the

kitchenware. Here are some features of die-cast pot and kitchenware molds:

1. High temperature resistant materials: Molds usually need to be made of materials such as high temperature resistant alloy steel to withstand the

high temperatures and pressures during the casting process.

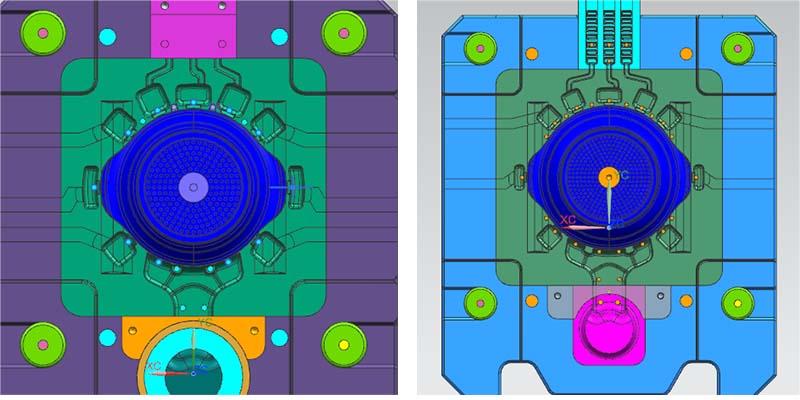

2. High precision and surface quality: Due to the high requirements for the appearance of kitchenware, the mold needs to have high precision to

ensure that the size and shape of the pot meet the design requirements and have a smooth and flat surface quality.

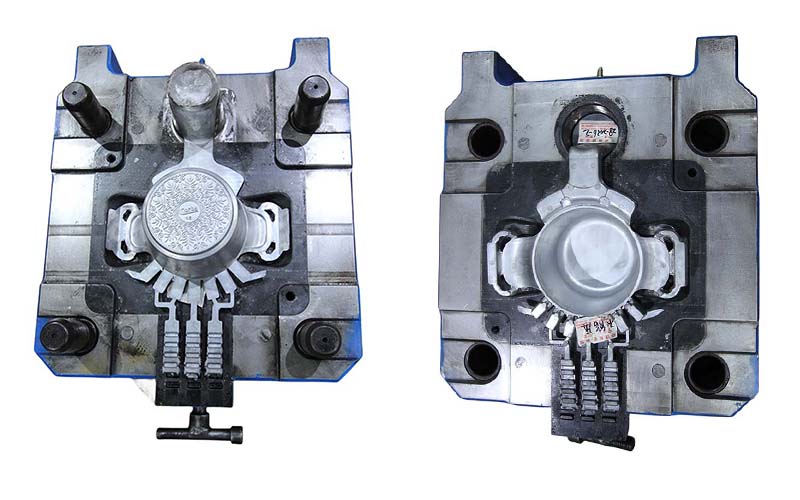

3. Complex internal structure design: Considering the special structures inside kitchenware, such as handles, grips, bottom grooves, etc., mold

design needs to reasonably consider how to realize these complex structures.

4. Cooling system: In order to speed up the cooling rate of castings and improve production efficiency, pot molds are usually equipped with an

effective cooling system, which can reduce the mold temperature in time during the casting process, avoid hot cracking and increase the

service life of the mold.

5. Anti-wear and durable: Since the metal has a certain wear effect on the mold surface during the die-casting process, the mold needs to

have high wear resistance to extend the service life of the mold.

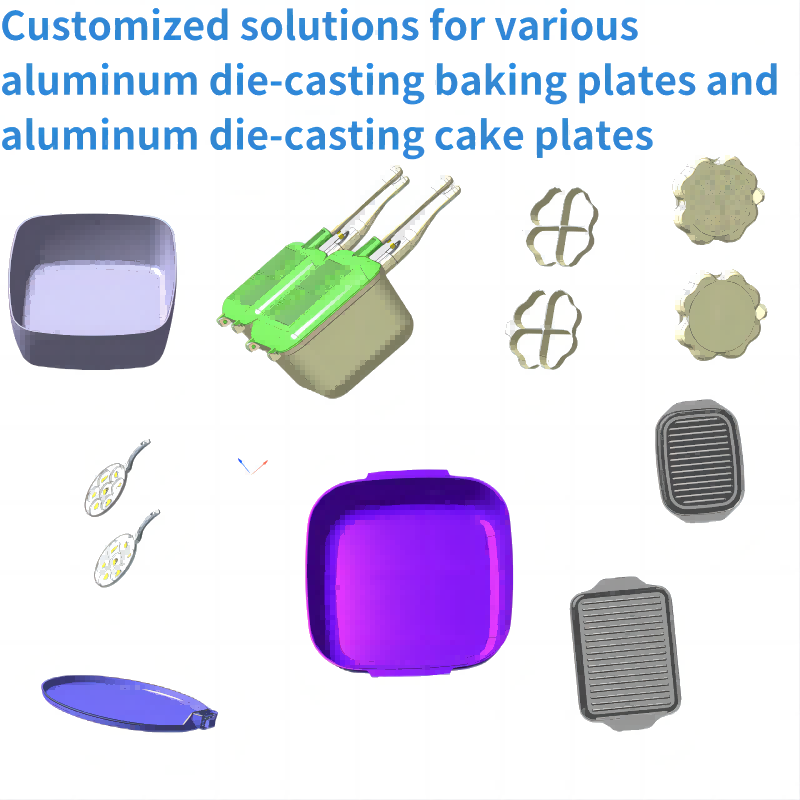

6. Quick replacement and easy maintenance: In order to adapt to the production needs of different types of kitchenware, mold design

should consider the ability to quickly replace the mold, while also making it easy to maintain the mold and replace parts.

7. Production efficiency: Molds need to have high production efficiency and be able to achieve a fast production cycle while ensuring

product quality to meet market demand.

8. Production cost control: Considering the cost of mold manufacturing, the design needs to simplify the structure as much as possible,

reduce material waste, and reduce energy consumption and production costs during the production process.

To sum up, the characteristics of die-cast pot and kitchenware molds include high-temperature resistant materials, high precision and

surface quality, complex internal structure design, cooling system, anti-wear and durability, quick replacement and easy maintenance,

production efficiency, and production cost control. These features can ensure the stability, efficiency and quality of the mold in the

production of pots and kitchenware.

|

Shaping Mode |

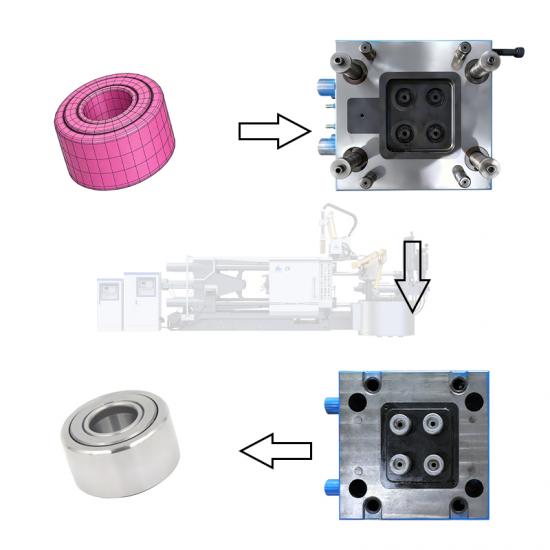

Die Casting |

|

Product Material |

Steel |

|

Product |

Pot mold |

|

ApplicationMould material |

45#/50#/P20/718/2738/NAK80/S136 |

|

Surface treatment |

Polish. Etched. Texture |

|

Size |

Customized Size |

|

Type |

Mold Tool |

|

Mould Life |

500000shots |

die-casting machines to meet the needs of different customers.