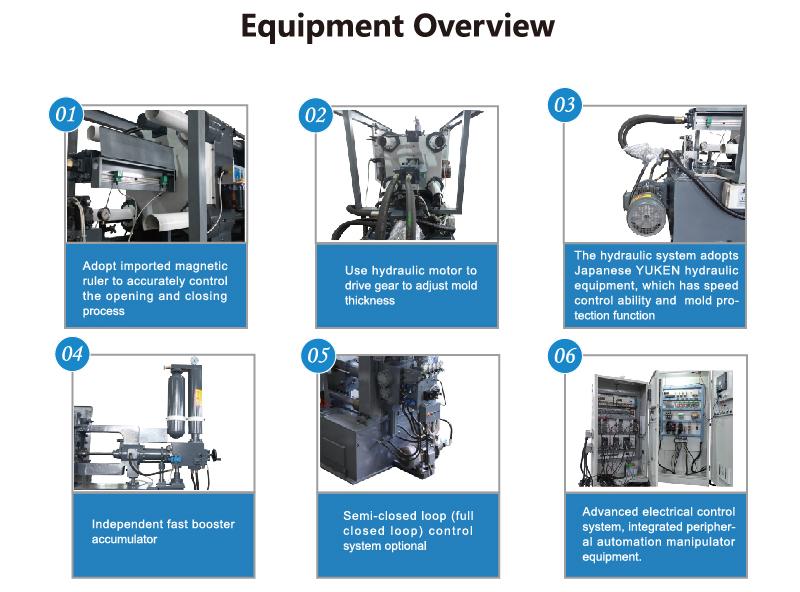

Feature

Features of utility knife shell die-casting machine:

1. Precision casting capability: Utility knife shells usually need to have precise sizes and shapes, so the

Utility Knife Shell Die-casting Machine has high-precision casting capabilities to ensure that the produced

knife shells meet the design requirements.

2. Application of high-strength materials: In order to ensure that the utility knife shell has sufficient

durability and strength, die-casting machines usually use high-strength materials, such as stainless steel,

aluminum alloy, etc.

3. Efficient production capacity: Since utility knife shells are commonly used items, production efficiency

is crucial to manufacturers. The utility knife shell die-casting machine has efficient production capacity and

can produce large quantities of knife shells quickly and stably.

4. Automated control system: Equipped with advanced automated control system, it can realize fully

automatic production, reduce manual intervention, and improve production efficiency and consistency.

5. Flexibility and adjustability: The designs of utility knife shells are diverse, so the utility knife shell

die-casting machine needs to have flexible production line settings and adjustable production parameters

to meet the production needs of different knife shells.

6. Quality control system: The strict quality control system ensures that the quality of the produced knife

shells is stable and reliable and meets relevant standards and requirements.

7. Energy saving and environmental protection: Modern utility knife shell die-casting machines have the

characteristics of energy saving and environmental protection. They use advanced energy-saving

technology and environmentally friendly materials to reduce energy consumption and emissions, and

meet environmental protection requirements.

8. Reliability and stability: The die-casting machine has a solid structure, reliable operation, and can work

continuously for a long time without damage, ensuring the stability and continuity of the production line.

Specification

| LH series of standard parameter table (280 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 2800 |

| Opening stroke | mm | 460 |

| Die thickness(Min--Max) | mm | 250~650 |

| Space between tie bars | mm | 560*560 |

| Ejector stroke | mm | 100 |

| Ejector force | KN | 110 |

| Injection position(0 as center) | mm | 0,-160 |

| Injection force(intensification) | KN | 330 |

| Injection stroke | mm | 380 |

| Plunger diameter | mm | ¢50 ¢60 ¢70 |

| lnjection weight(aluminum) | Kg | 3 |

| Casting pressure (intensification) | MPa | 168/116/85 |

| Max. casting area(40Mpa) | CM2 | 700 |

| Injection plunger penetration | mm | 140 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 15 |

| Dimensions (L*W*H) | m | 6.4*1.7*2.8 |

| Machine lifting reference weight | T | 12 |

| Oil tank capacity | L | 650 |

(Due to the continuous progress of science and technology,the picture,parameter configuration,etc,

will not be changed without notice)

Die casting product

Features of utility knife die castings:

1. High precision: Utility knife die-casting parts usually require high-precision processing capabilities to ensure

that the size, shape and fit of the tool meet the design requirements and ensure its functionality and reliability.

2. Excellent strength and durability: Utility knife die-casting parts need to have good strength and durability,

be able to withstand various forces and pressures during use, and ensure long-term stable operation of the knife.

3. Complex shapes: Utility knife die-casting parts may have complex shapes and structures to meet different

functions and usage requirements, such as the design of blades, handles and other components.

4. Surface treatment: In order to improve the appearance quality and corrosion resistance of utility knives,

utility knife die-casting parts usually require surface treatment, such as polishing, chrome plating, spraying,

etc., to enhance their surface smoothness and anti-oxidation properties.

5. Lightweight design: In order to improve the carrying convenience and operating comfort of the utility knife,

the die-casting part of the utility knife may adopt a lightweight design to reduce the overall weight and

improve the flexibility and ease of use of the knife.

6. Multi-material adaptability: Utility knife die-casting parts can be made of a variety of metal materials,

such as aluminum alloy, stainless steel, etc., to meet the specific requirements of different knives and the

use needs in the working environment.

7. Process requirements: The manufacturing of utility knife die-casting parts involves a variety of processes,

including mold design, material selection, casting, cooling, deburring, processing, etc. Each link needs to

be strictly controlled to ensure that the final product quality meets standard requirements.

8. Cost control: When manufacturing utility knife die-casting parts, cost control needs to be considered,

including material costs, production process costs, labor costs, etc., to ensure that product prices are

competitive.

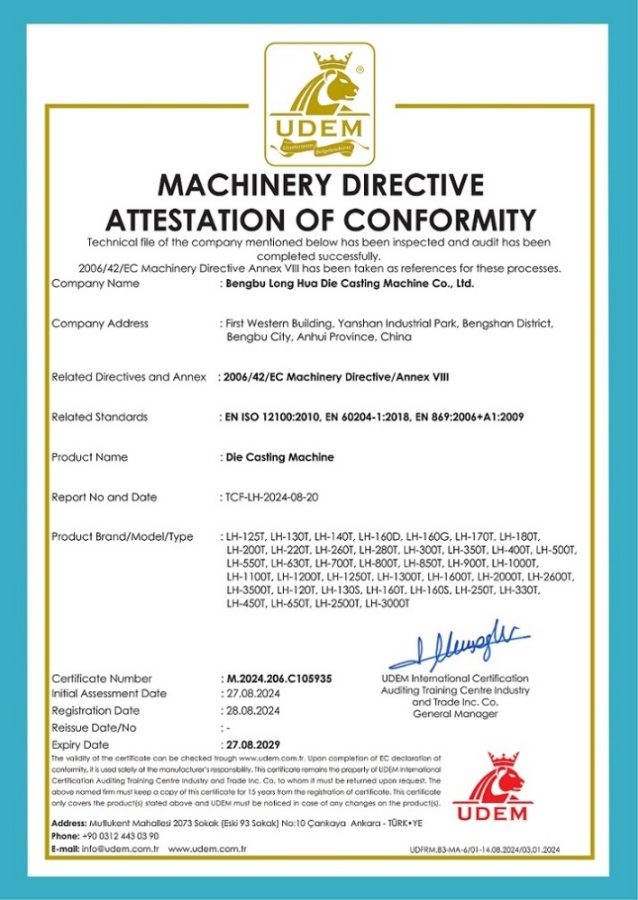

ABOUT US

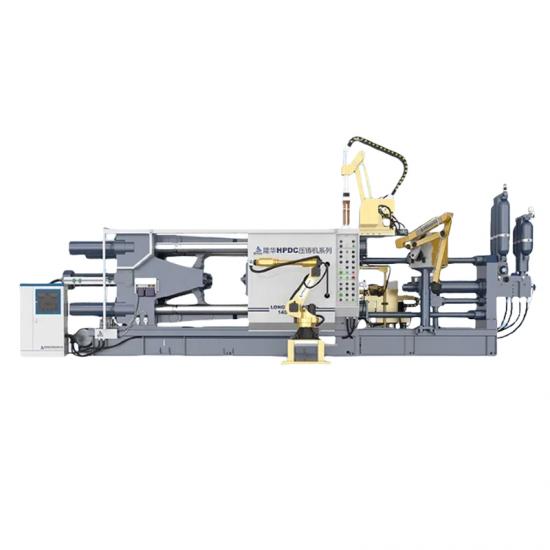

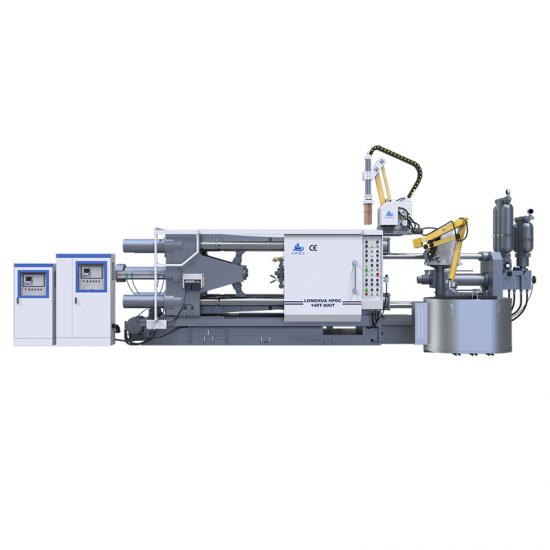

Bengbu Longhua Die Casting Machine Co.,Lid is a company based in Bengbu City,Anhui Province,

China.It specializes in the manufacturing of die casting machines and related equipment.

Established in 1982,Longhua Die Casting Machine Co.,Ltd has been involved in the die casting

industry for several decades.The company focuses on research,development,production,and

sales of various types of die casting machines.The company's product range covers cold chamber

die-casting machines,die-casting manipulators,industrial robots and peripheral equipment of

die-casting machines to meet the needs of different customers.