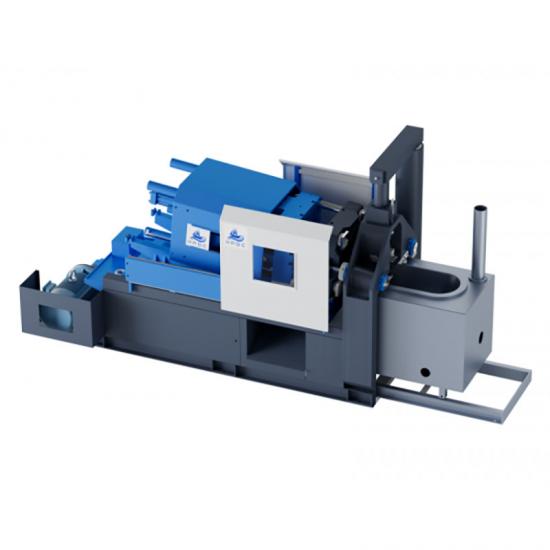

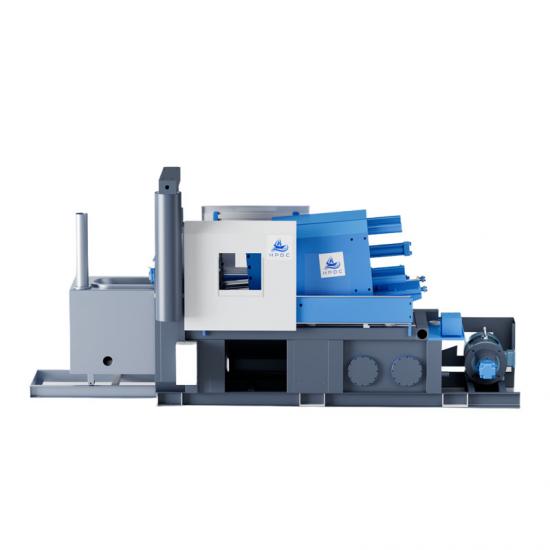

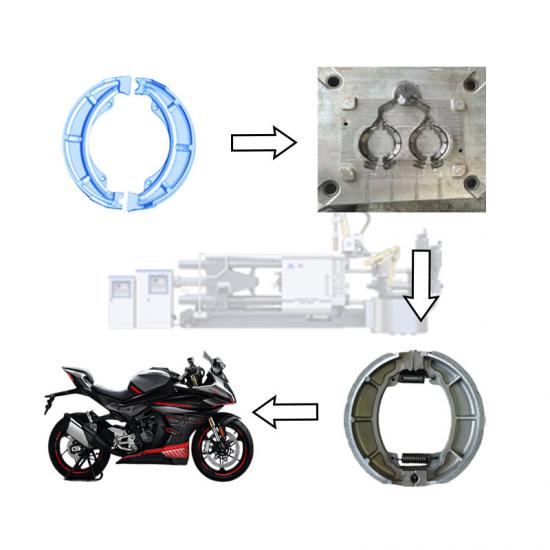

Hot chamber die-casting machines are widely used in industrial sectors such as automobiles, motorcycle parts, instruments and meters, daily hardware, and household appliances, especially for the production of small zinc alloy die-casting parts. Due to its high production efficiency and ease of automation, hot chamber die casting machines play an important role in the production of small parts.